Stirring kettle for producing winding adhesive, and stirring method thereof

A stirring method and a stirring tank technology, which are applied in the direction of mixing methods, mixer accessories, chemical instruments and methods, etc., can solve the problems of unsuitability for large-scale production requirements, inconvenient portability, low stirring efficiency of the stirring tank, etc., and achieve simple structure , improve stirring efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

[0043] A method for stirring a stirred tank for production of ring-wound rubber, comprising the following steps:

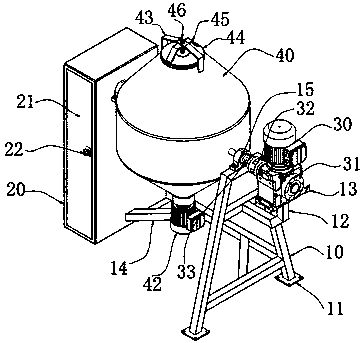

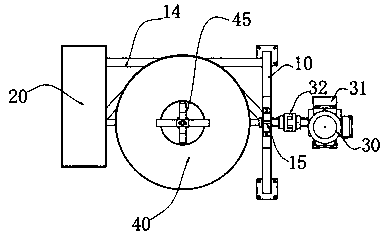

[0044] Step 1. Place the stirred tank at a suitable position, control the rotation of the motor a30 through the switch group 23, and adjust the reducer 31 so that the tank body 40 can be tilted to an angle that is convenient for feeding;

[0045] Step 2, by rotating the dovetail bolt 46, the kettle cover 44 is separated from the top opening of the kettle body 40, and feeding is carried out;

[0046] Step 3: after feeding, fix the kettle cover 44 to completely seal the kettle body 40, and control the rotation of the motor a30 through the switch group 23, so that the whole kettle body 40 is turned over and stirred;

[0047] Step 4. After the stirring is finished, control the opening of the kettle body 40 to tilt downward, open the kettle cover 44 and add it to the fiber-coated glue tank through a glass straw.

[0048] In the embodiment, specifical...

Example Embodiment

[0058] Experimental example 3

[0059] A method for stirring a stirred tank for production of ring-wound rubber, comprising the following steps:

[0060] Step 1. Place the stirred tank at a suitable position, control the rotation of the motor a30 through the switch group 23, and adjust the reducer 31 so that the tank body 40 can be tilted to an angle that is convenient for feeding;

[0061] Step 2, by rotating the dovetail bolt 46, the kettle cover 44 is separated from the top opening of the kettle body 40, and feeding is carried out;

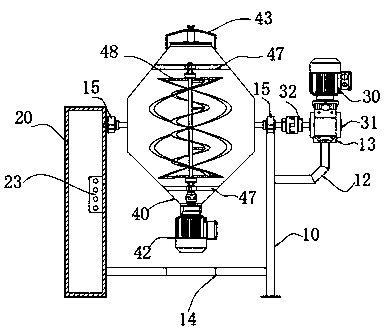

[0062] Step 3: After feeding, fix the kettle cover 44 to completely seal the kettle body 40, and simultaneously control the rotation of the motor a30 and the motor b42 through the switch group 23, and turn over and stir the kettle body 40;

[0063] Step 4. After the stirring is finished, control the opening of the kettle body 40 to tilt downward, open the kettle cover 44 and add it to the fiber-coated glue tank through a glass straw.

[0064]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap