Heating process of aluminum rod for aluminum extruding

A heating process and aluminum rod technology, which is applied in the field of aluminum profile processing, can solve problems such as uneven heating of aluminum rods, time-consuming and labor-intensive effects on product molding, etc., to achieve high-efficiency operation and improve high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

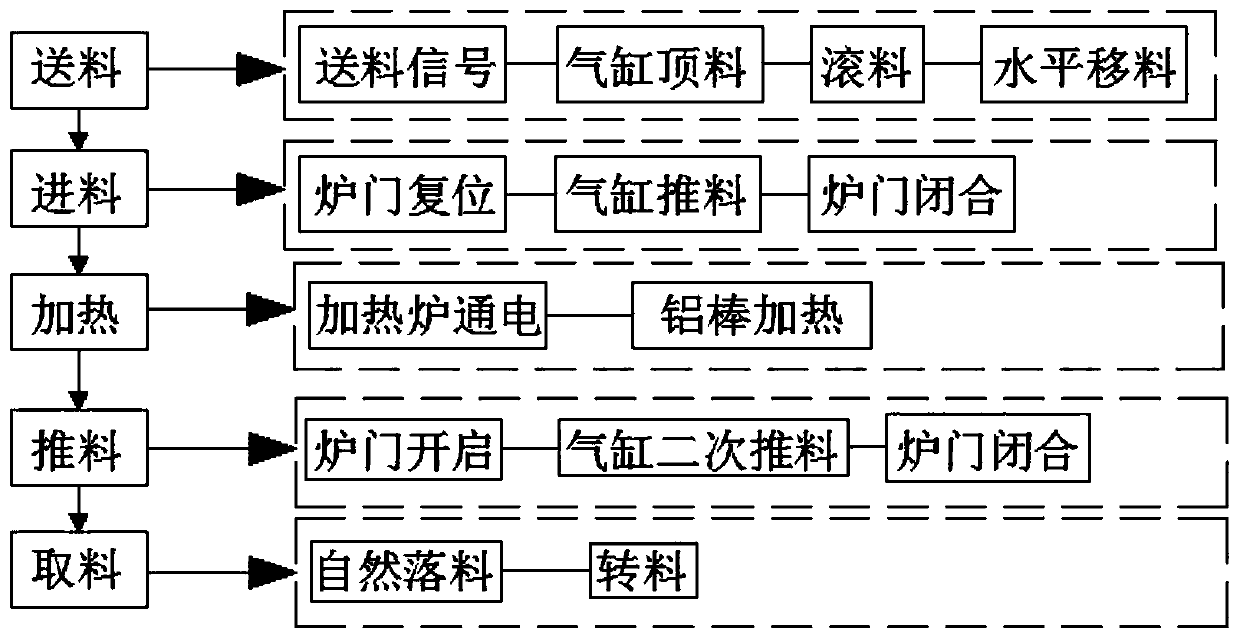

[0023] Such as figure 1 As shown, the aluminum rod heating process for aluminum extrusion includes the following steps:

[0024] The first step, feeding: the feeding system gives a feeding signal, the cylinder under the material plate moves up to lift the material, the aluminum rod slides along the material plate to the feeding table, and the feeding table is controlled to move to the position of the furnace mouth that needs to be supplemented by aluminum rods; The material table is a sliding arc-shaped plate structure, which can well hold the aluminum rods and align the aluminum rods with the aluminum rod channel at the mouth of the furnace.

[0025] Preferably, the feeding system in this embodiment adopts the synchronous hydraulic feeding system designed by Shenzhen Xipak Technology Co., Ltd., through which the opening and closing of the furnace door, the synchronous movement of the feeding platform, the upper and lower lifting of the cylinder, and the cylinder Push materia...

Embodiment 2

[0039] Such as figure 1 As shown, the aluminum rod heating process for aluminum extrusion includes the following steps:

[0040] The first step, feeding: the feeding system gives a feeding signal, the cylinder under the material plate moves up to lift the material, the aluminum rod slides along the material plate to the feeding table, and the feeding table is controlled to move to the position of the furnace mouth that needs to be supplemented by aluminum rods; The material table is a sliding arc-shaped plate structure, which can well hold the aluminum rods and align the aluminum rods with the aluminum rod channel at the mouth of the furnace.

[0041] Preferably, the feeding system in this embodiment adopts the synchronous hydraulic feeding system designed by Shenzhen Xipak Technology Co., Ltd., through which the opening and closing of the furnace door, the synchronous movement of the feeding platform, the upper and lower lifting of the cylinder, and the cylinder Push materia...

Embodiment 3

[0052] Such as figure 1 As shown, the aluminum rod heating process for aluminum extrusion includes the following steps:

[0053] The first step, feeding: the feeding system gives a feeding signal, the cylinder under the material plate moves up to lift the material, the aluminum rod slides along the material plate to the feeding table, and the feeding table is controlled to move to the position of the furnace mouth that needs to be supplemented by aluminum rods; The material table is a sliding arc-shaped plate structure, which can well hold the aluminum rods and align the aluminum rods with the aluminum rod channel at the mouth of the furnace.

[0054] The second step, feeding: the feeding system sends a signal to the furnace door, the furnace door resets and moves up, exposing the aluminum rod channel, the cylinder behind the feeding table pushes the aluminum rod into the aluminum rod channel, and the furnace door falls to block it after the feeding is completed The aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com