High-speed pneumatic sorting and recycling device for plastic bottles

A recycling device and technology for plastic bottles, applied in the field of high-speed pneumatic sorting and recycling devices for plastic bottles, can solve the problems of inconvenient sorting and recycling of beverage bottles, inconvenient sorting and recycling, low sorting efficiency, etc., saving manpower and material resources, improving operability, The effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

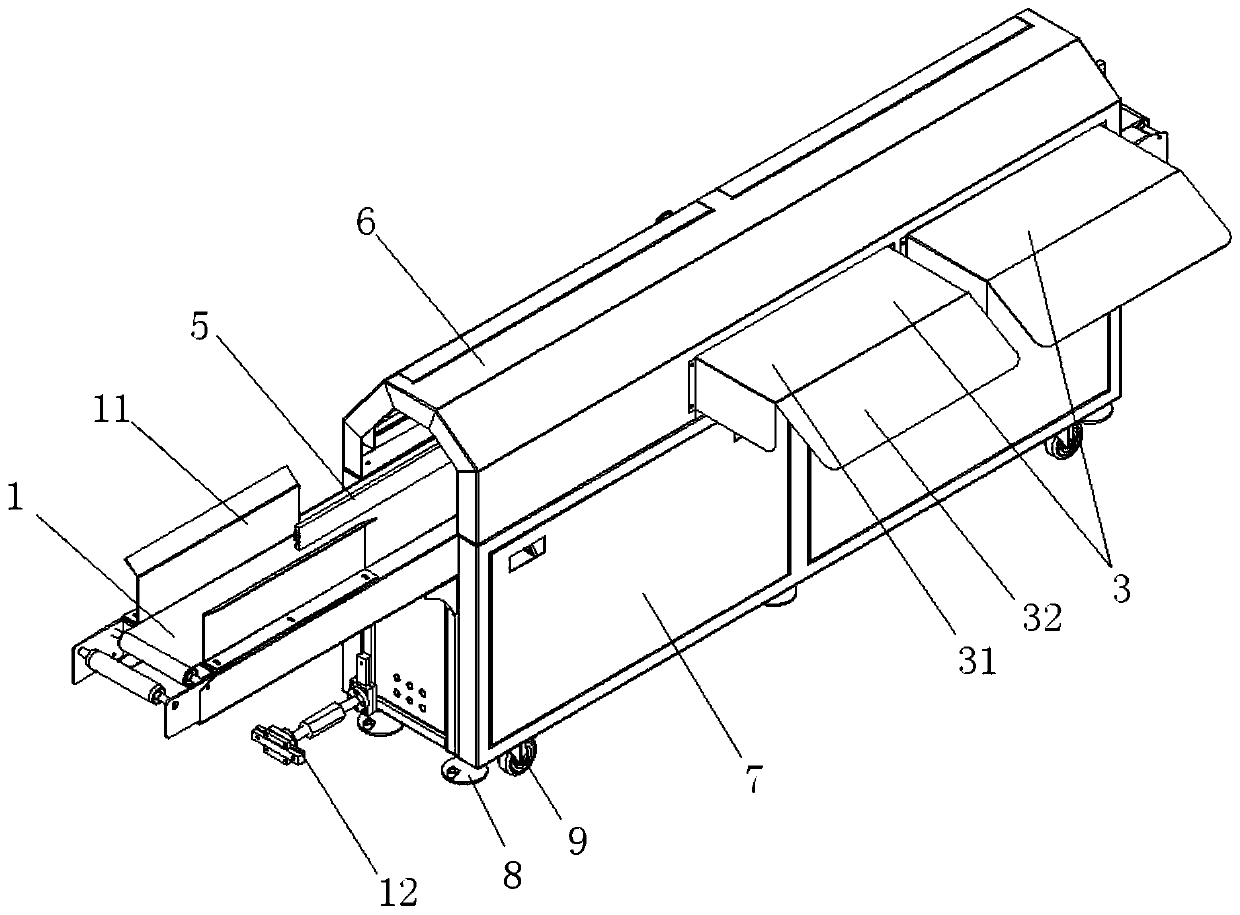

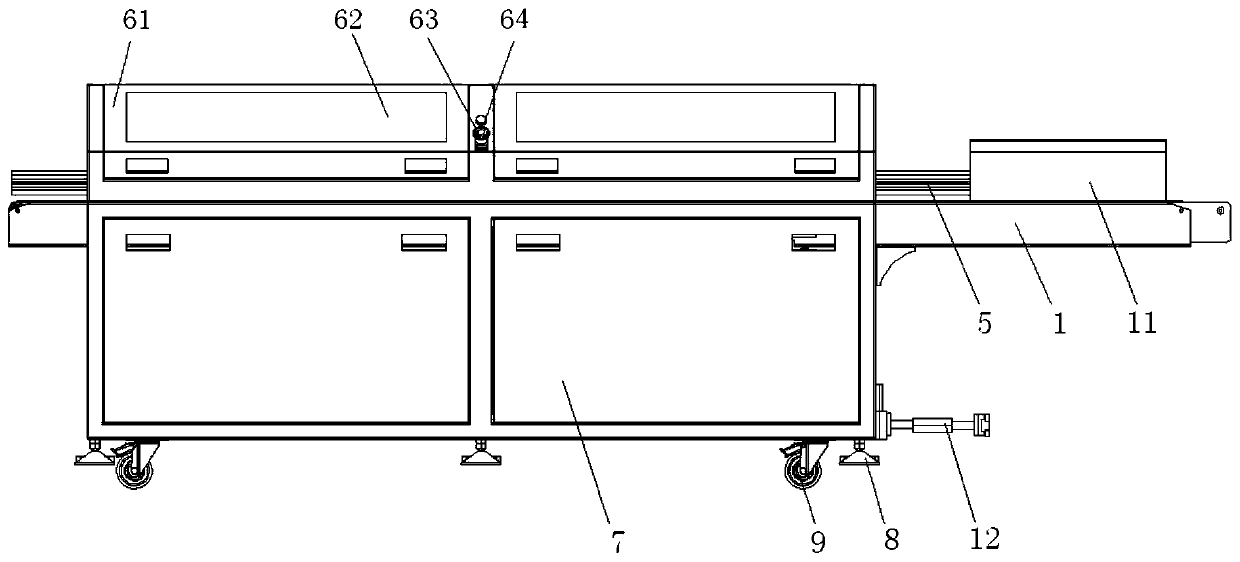

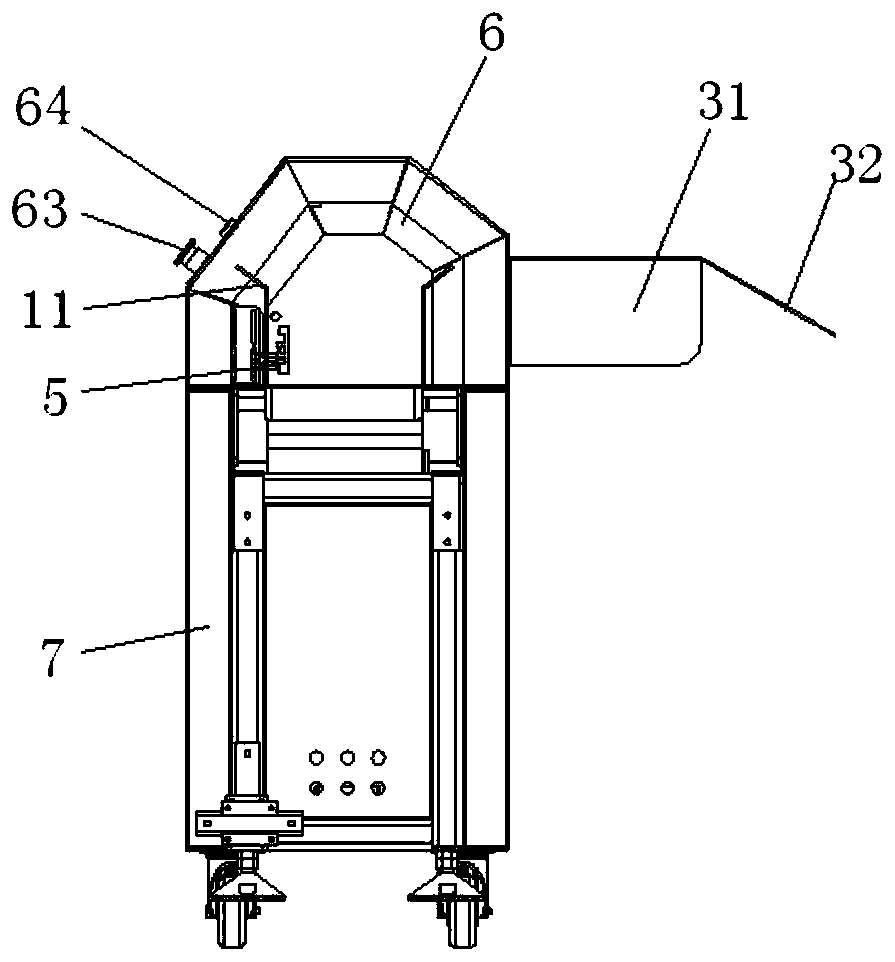

[0029] Refer to attached Figures 1 to 5 As shown, the high-speed pneumatic sorting and recycling device for plastic bottles in this embodiment includes a belt transmission mechanism 1, and a high-pressure air injection mechanism 2 and a classification recovery mechanism 3 that are respectively arranged oppositely on both sides of the belt transmission mechanism 1. The high-pressure air injection mechanism 2 includes Multiple sets of high-pressure gas nozzles 21 and the gas storage mechanism and control mechanism connected thereto. The sorting recovery mechanism 3 includes multiple recovery channels 31 set opposite to the multiple sets of high-pressure gas nozzles 21. The control mechanism is used to receive plastic bottles. Identify the identification information of the identification mechanism, and control the opening or closing of the high-pressure gas nozzle 21 opposite to the corresponding recovery channel 31 according to the identification information, so as to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com