A connection structure between modular car body modules of a shunting locomotive

A technology for shunting locomotives and connecting structures, which is applied in the direction of railway car body, railway car body parts, climate sustainability, etc. It can solve the problems of inconvenient disassembly, high manufacturing cost, complex structure, etc., and achieves good adhesion and good appearance. Beautiful, simple and reliable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that in the following embodiments, the rear engine room, driver's room, power room, and cooling room can be referred to as vehicle rooms. When one or several specific vehicle rooms are mentioned in the foregoing description, it should be clear at this time Which one or several car rooms are referred to by car rooms.

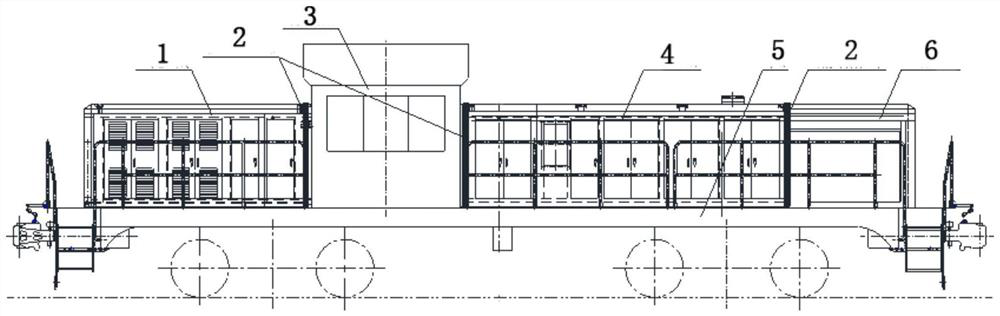

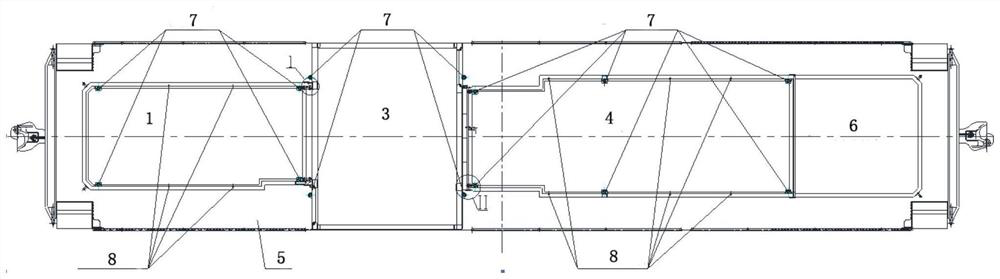

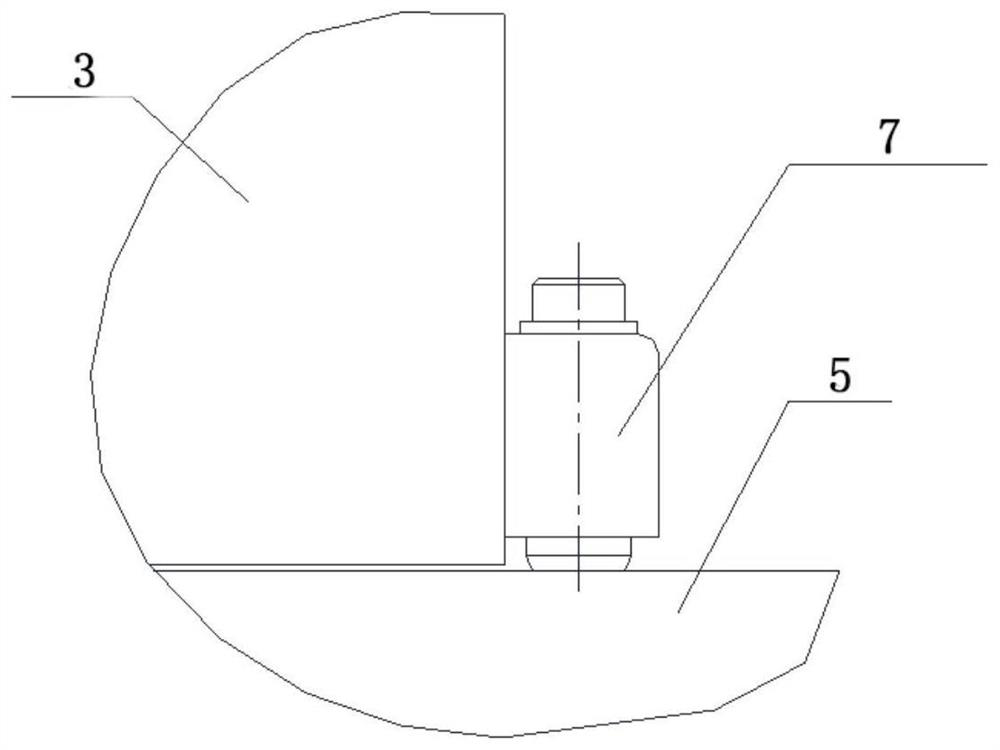

[0036] Such as figure 1 , figure 2 The connection structure between the modular car body modules of the shunting locomotive shown includes four compartments: rear engine compartment 1, driver's compartment 3, power compartment 4, cooling compartment 6, frame 5 at the bottom of the compartment, rear engine compartment , the driver's cab, the power room, and the cooling chamber are installed on the frame from left to right, and the connecting plate structure is used to connect the various compartments. The connecting plate structure incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com