Wine barrel

A wine barrel and barrel body technology, which is applied in the field of wine barrels and beverage containers, can solve the problems of poor structural stability of the upper and lower valve seats, and achieve the effect of ensuring the stability of use and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

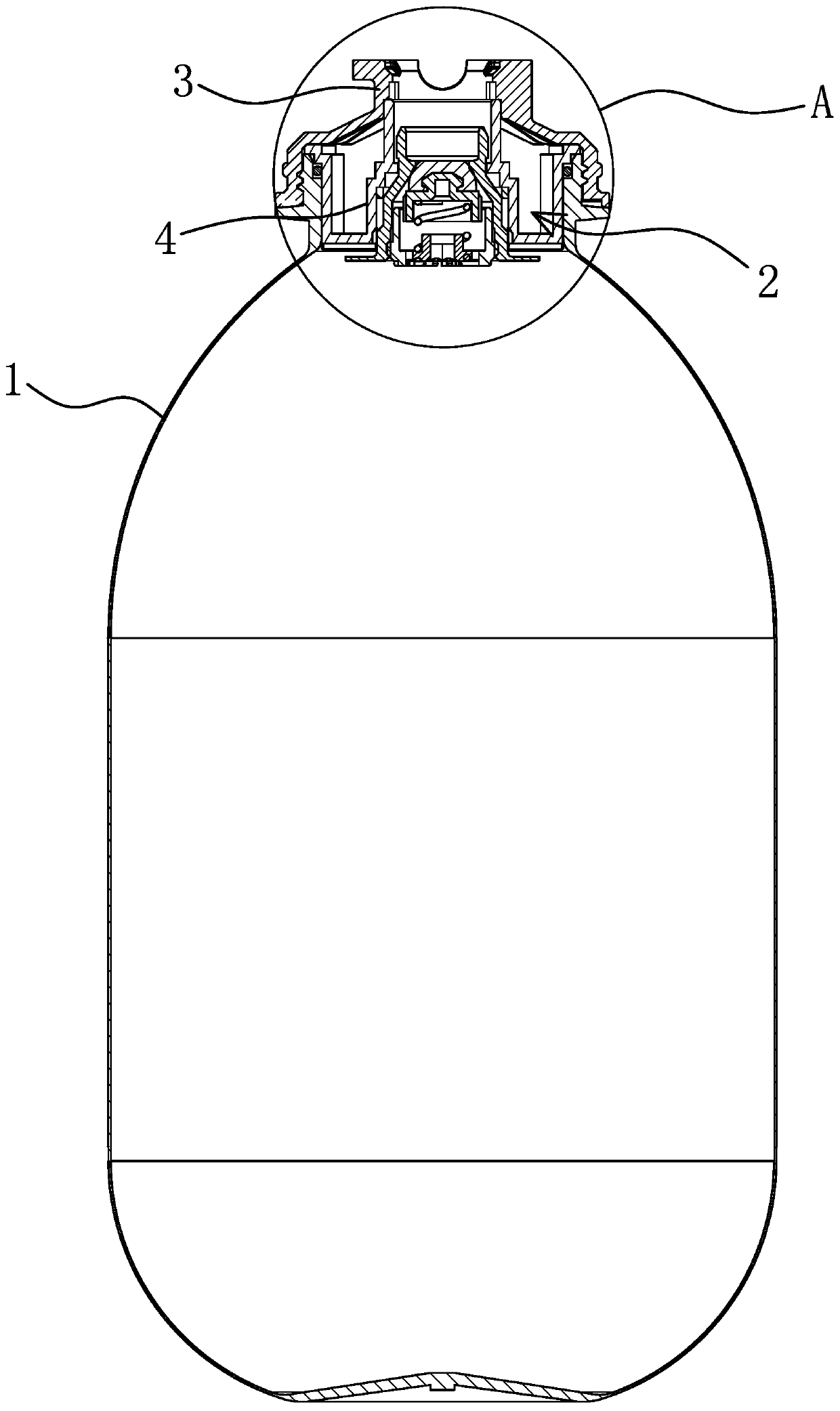

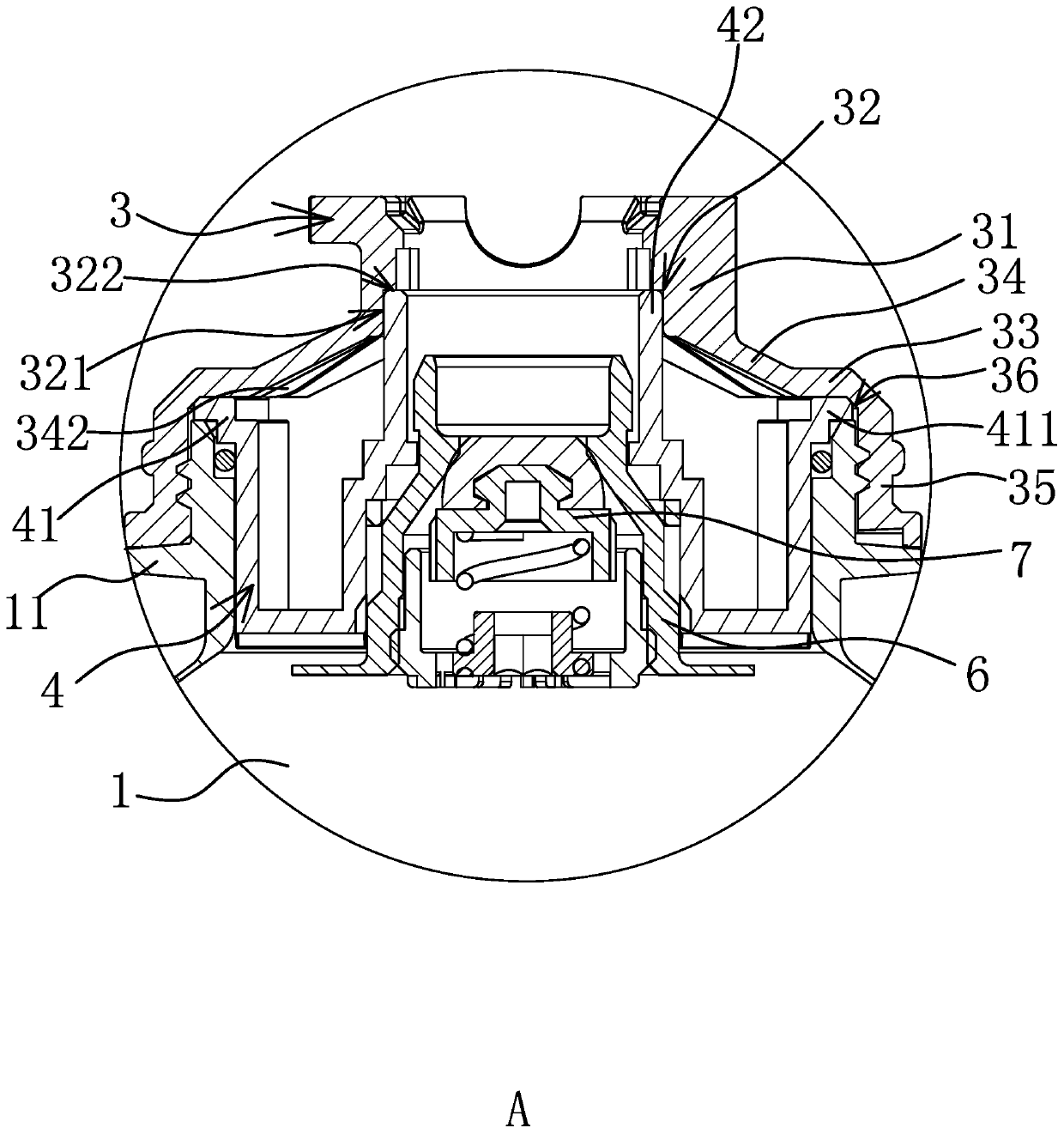

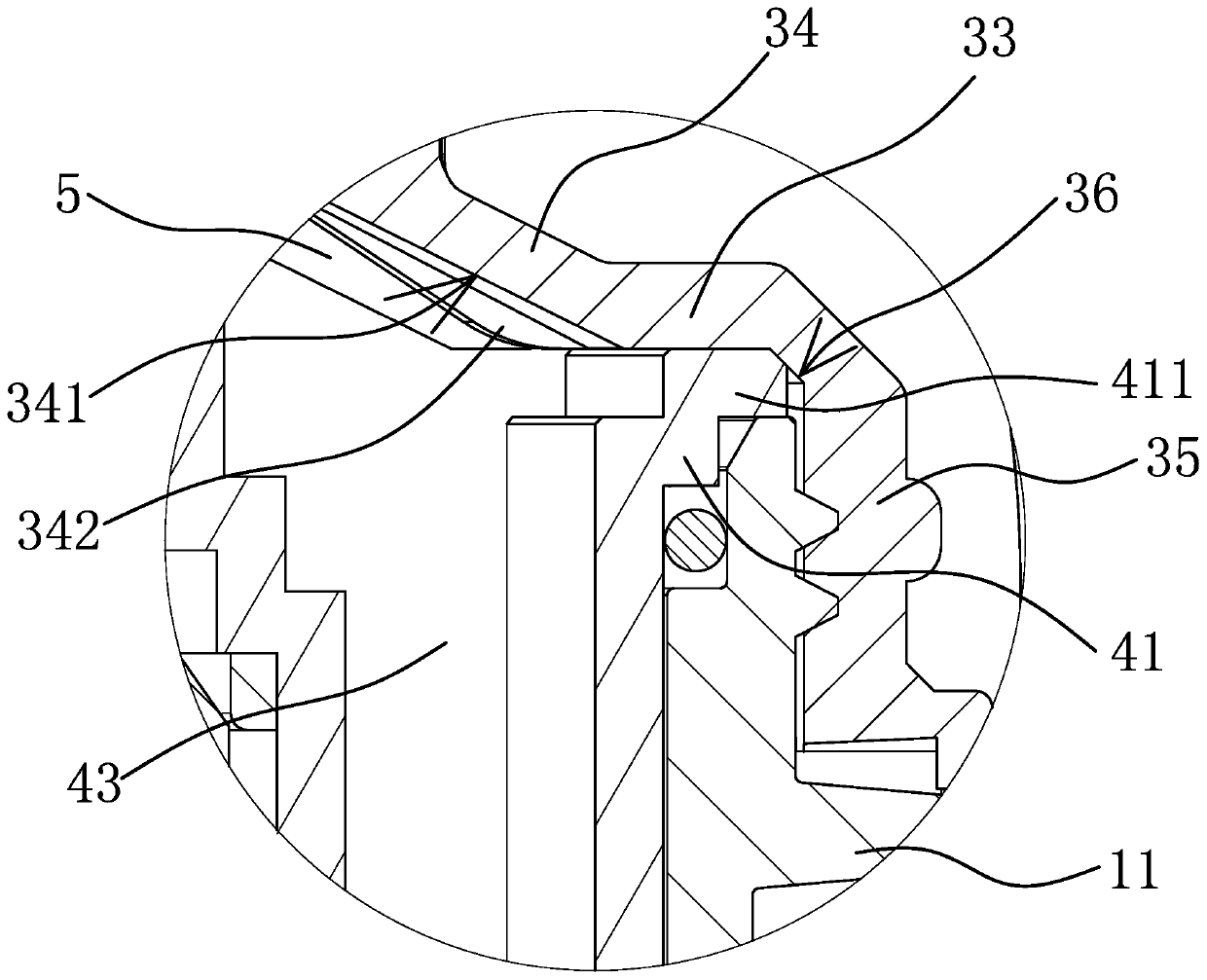

[0032] Such as figure 1 , figure 2 , Figure 5 The wine barrel shown includes a barrel body 1 and a plastic wine spear 2 arranged above the barrel body 1. The wine spear 2 includes an upper valve seat 3 and a lower valve seat 4 positioned below the upper valve seat 3. The lower valve seat 4 is The cross-section is a U-shaped annular structure and includes ring-shaped outer edge 41 and inner edge 42. The inner edge 42 is set higher than the outer edge 41, and the inner edge 42 and the outer edge of the lower valve seat 4 Between the 41, there are several connecting plates 43 connecting the inner edge 42 and the outer edge 41. The connecting plates 43 can respectively abut against the inner edge 42 and the outer edge 41 and prevent the inner edge 42 from reaching the outer edge 41. Approach and produce deformation to ensure structural stability. And in the lower valve seat 4, structures such as valve body 6 and valve core 7 are arranged, between the lower valve seat 4 and th...

Embodiment 2

[0039] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference lies in that: an outwardly protruding annular support flange 11 is provided on the neck of the barrel body 1, and the anti-reversal structure includes a support flange 11 The limit groove on the surface, the upper valve seat 3 is provided with a number of blocks protruding downwards, and the blocks are connected to the lower surface of the clamping connection part 35 by springs. In this manner, the reverse rotation of the upper valve seat 3 can also be effectively prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com