Electromagnetic driving device and gas proportional valve with same

An electromagnetic drive and magnet guide technology, which is applied in the direction of electromagnets, valve devices, electrical components, etc., can solve the problems that affect the reliability of electromagnetic drive devices and the inability of moving coil parts to obtain sufficient magnetic thrust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

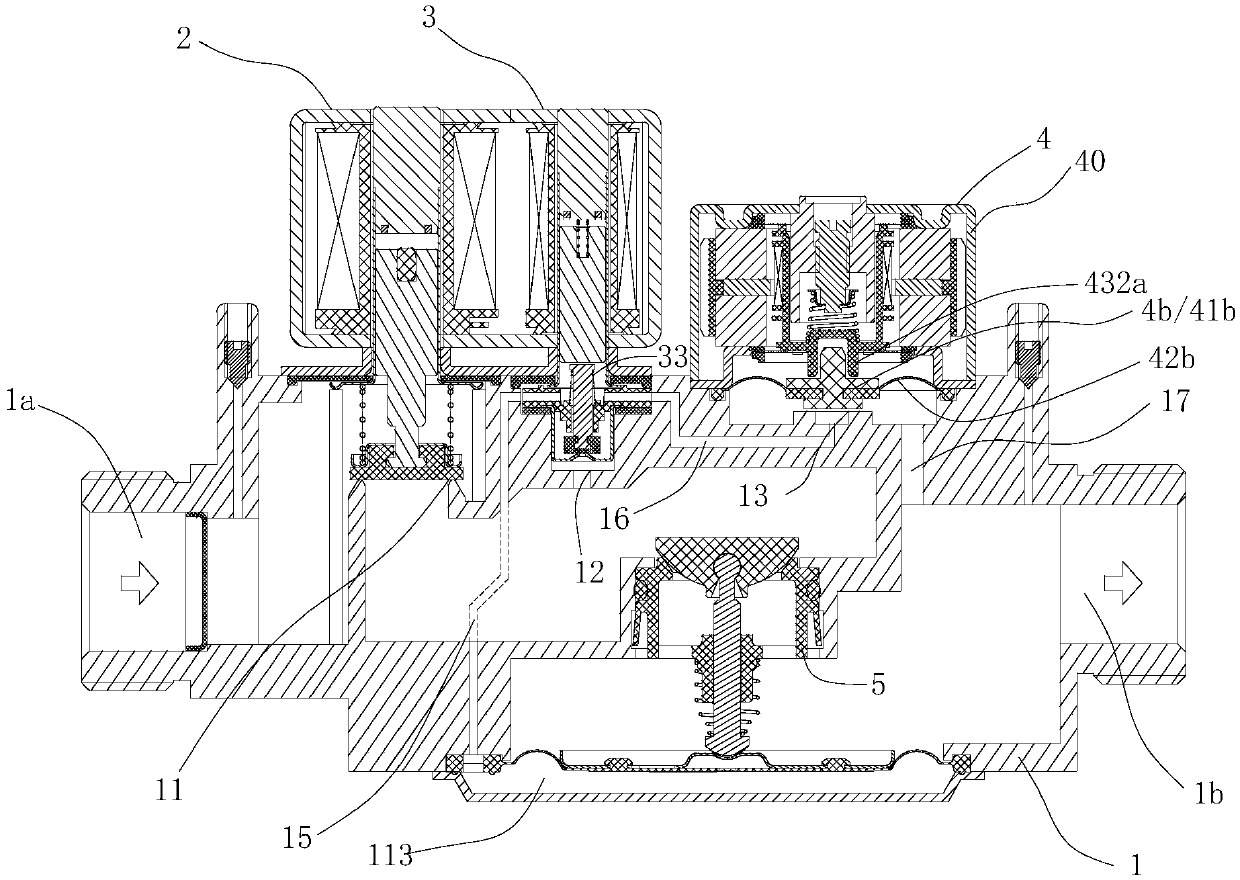

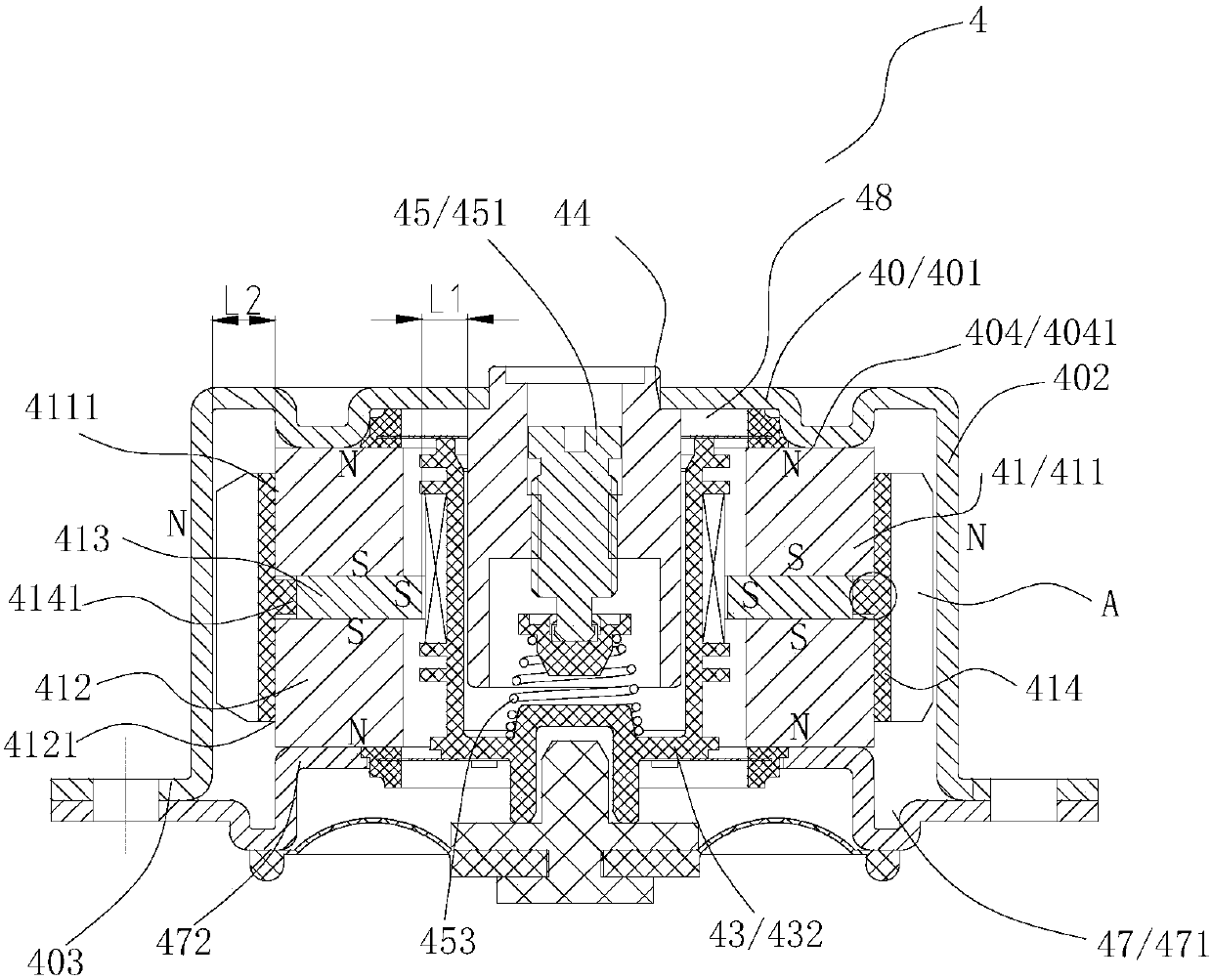

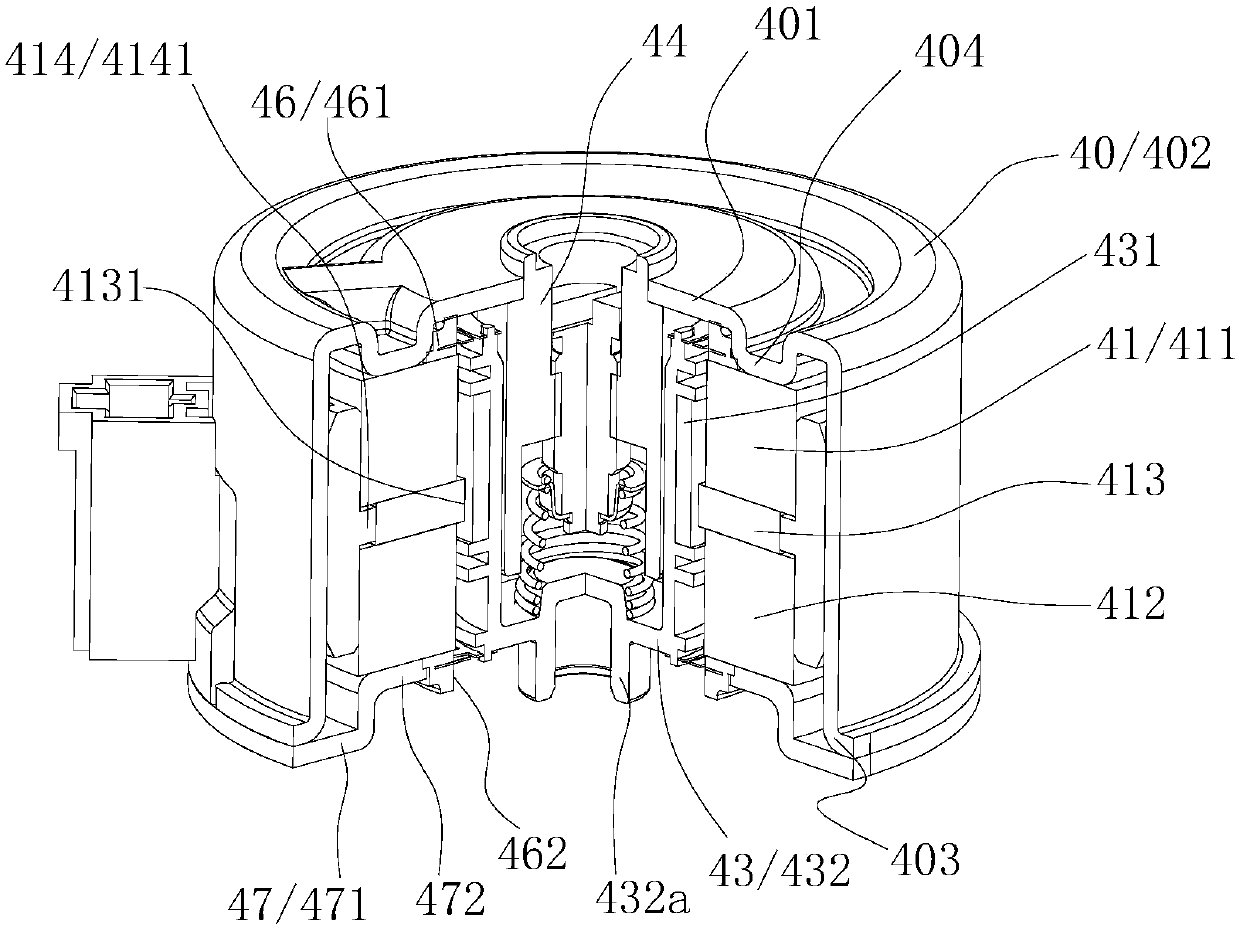

[0010] Such as figure 1 In the shown electromagnetic driving device, the electromagnetic driving device is provided with a cavity 48. The electromagnetic driving device includes a casing 40 and a magnetically conductive core 44. The casing 40 includes at least a magnetically conductive part, and the magnetically conductive part includes a top wall part 401 and a side wall part 402. , the top wall portion 401 is fixedly connected with the magnetically conductive core 44, the outer peripheral portion of the magnetically conductive core 44 is provided with a moving coil assembly 43, and the moving coil assembly 43 can reciprocate along the axial direction of the magnetically conductive core 44, and the electromagnetic drive part also includes a magnet Component 41, the magnet component 41 includes a first permanent magnet 411, a second permanent magnet 412, and a soft magnet 413 located between the first permanent magnet 411 and the second permanent magnet 412. It should be noted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com