Electronic expansion valve

A technology of electronic expansion valve and valve body, which is applied in the direction of lifting valve, valve details, valve device, etc., and can solve the problems of output shaft eccentricity and electronic expansion valve unreliable actuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

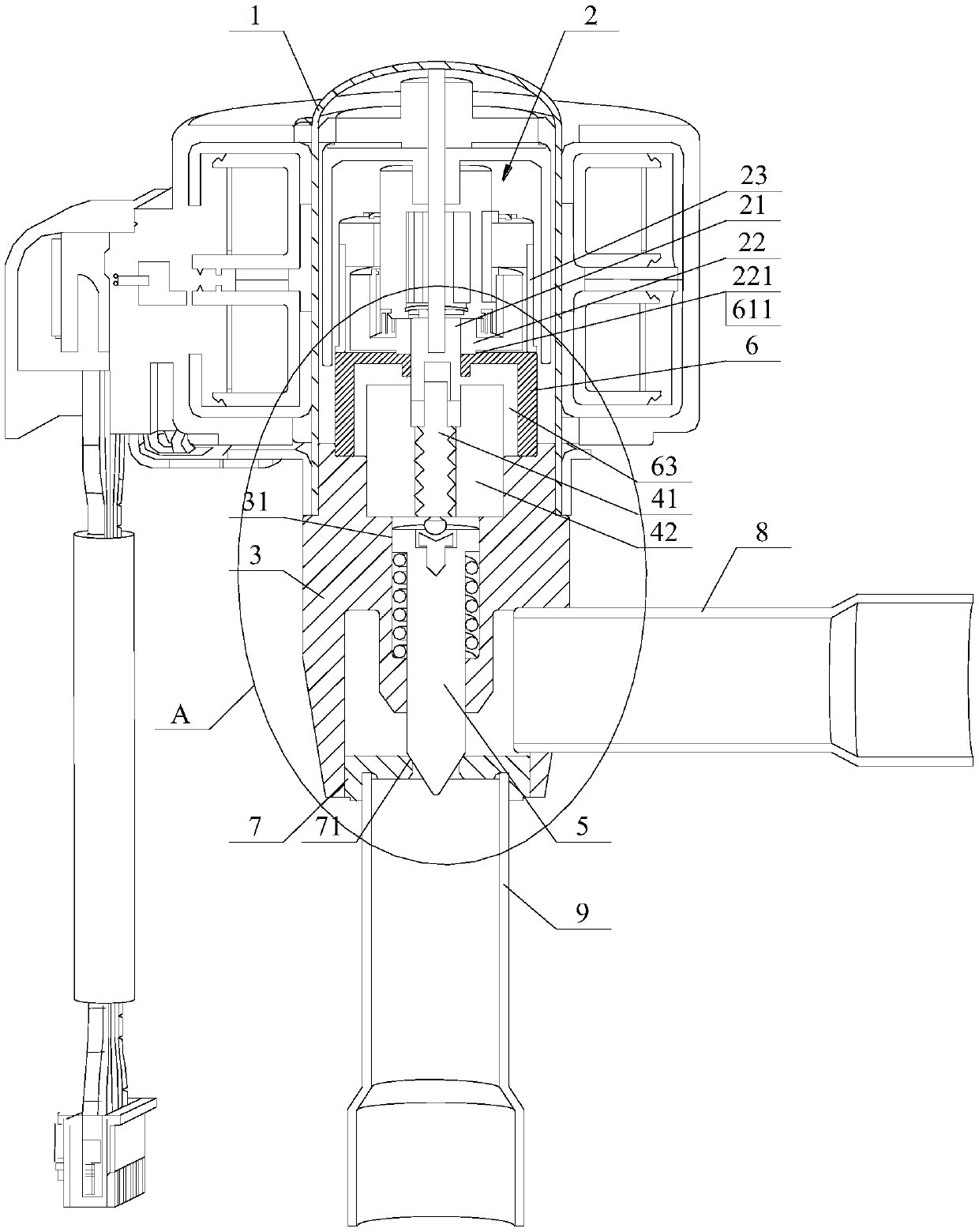

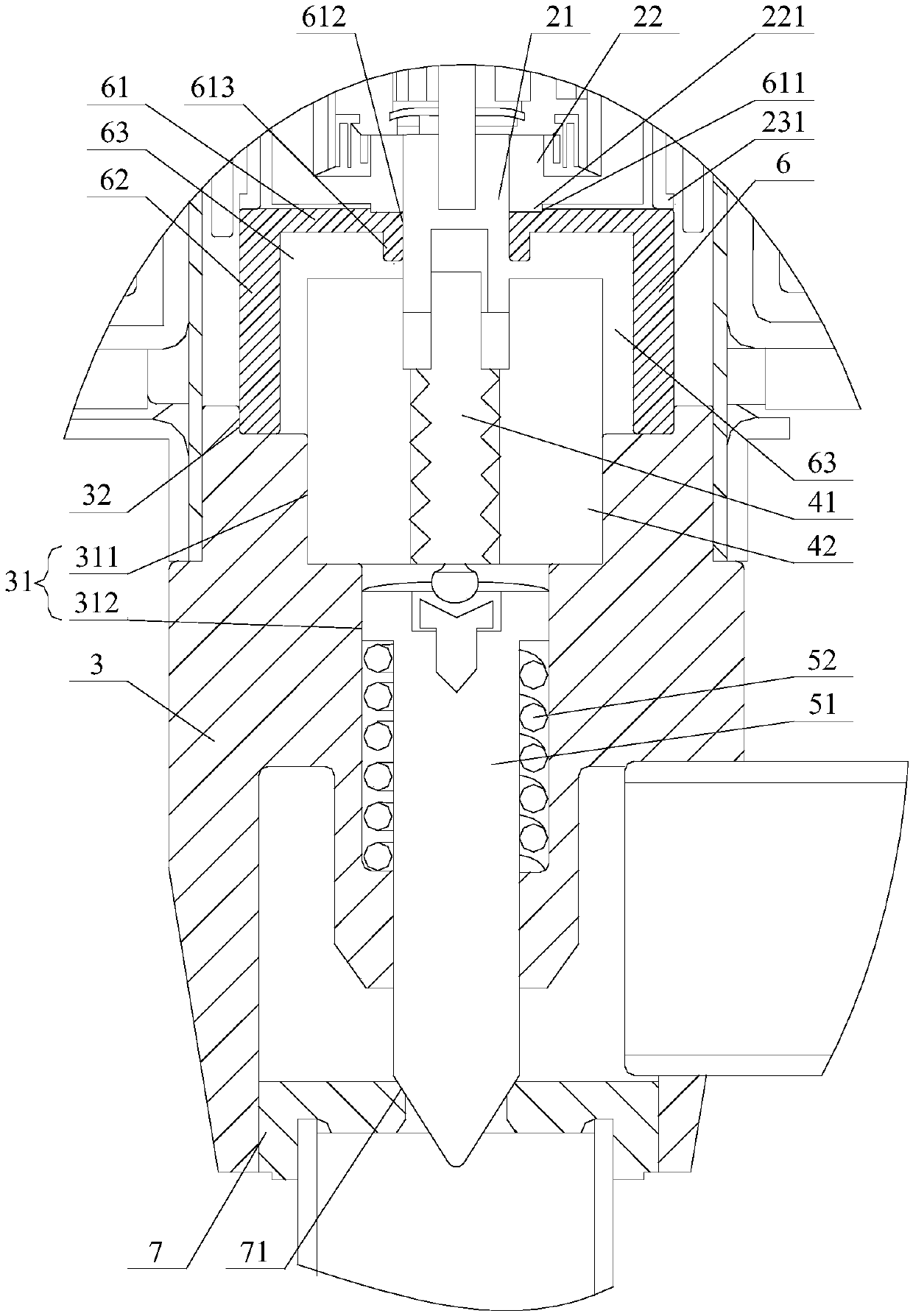

[0014] Please refer to figure 1 , which is a schematic diagram of the overall structure of the electronic expansion valve described in this embodiment.

[0015] The electronic expansion valve includes a housing 1 and a planetary gear reduction device 2 arranged in the housing 1. Its specific transmission principle is the same as that of the prior art. The output gear 22 and the output shaft 21 output power to the screw rod 41 of the nut drive assembly to drive the valve core assembly 5 to carry out axial lifting movement, so as to approach or stay away from the valve port 71 on the valve core seat 7 to realize the adjustment of the valve opening. adjust.

[0016] The housing 1 of the electronic expansion valve is fixedly connected to the valve body 3, the valve body 3 is fixedly connected to the valve seat core 7, the valve body 3 is provided with a cavity 31, at least part of the nut drive assembly (41, 42) and at least part of the valve needle The component 5 is located in...

Embodiment 2

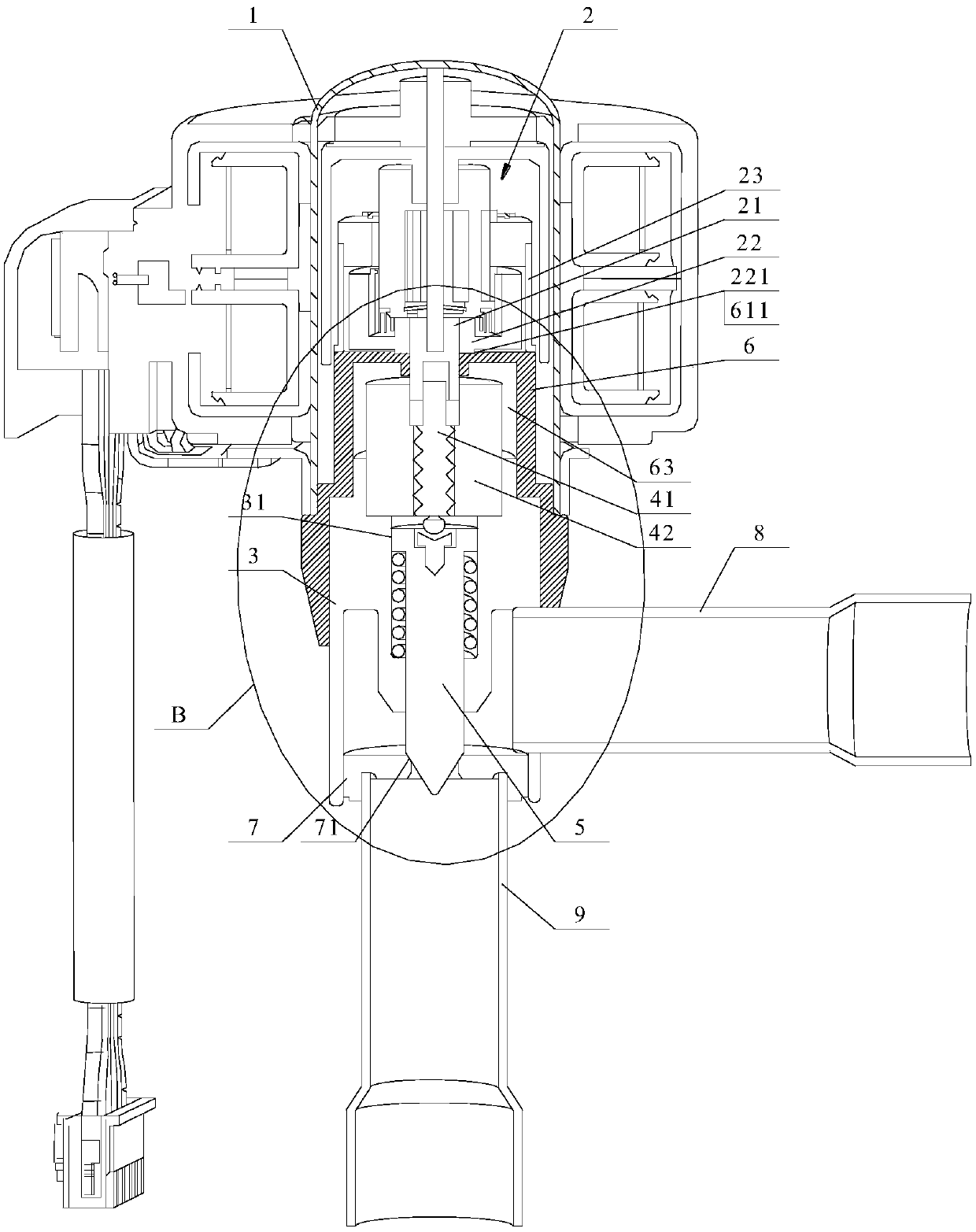

[0025] See image 3 , which is a schematic diagram of the overall structure of the electronic expansion valve described in Embodiment 2.

[0026] The difference between this solution and the first embodiment is that the fixing methods of the support member 6 and the valve body 3 are different. In order to clearly show the differences and connections between the two, the same functional components are shown with the same symbols in the drawings.

[0027] As shown in the figure, the extension portion 62 of the support member 6 has a small diameter portion 621, a large diameter portion 623 and a first step portion 622, the small diameter portion 621 is connected to the main body portion 61, and the small diameter portion 621 and the large diameter portion 623 pass through the first step portion 622 connection; the lower end of the housing 1 is fixedly connected to the valve body 3 through the extension 62 . Specifically, it can be fixed by welding or pressing. further combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com