Petroleum production pipeline rack

A pipe rack and petroleum technology, applied in the direction of pipe racks, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of unable to fix and clamp pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

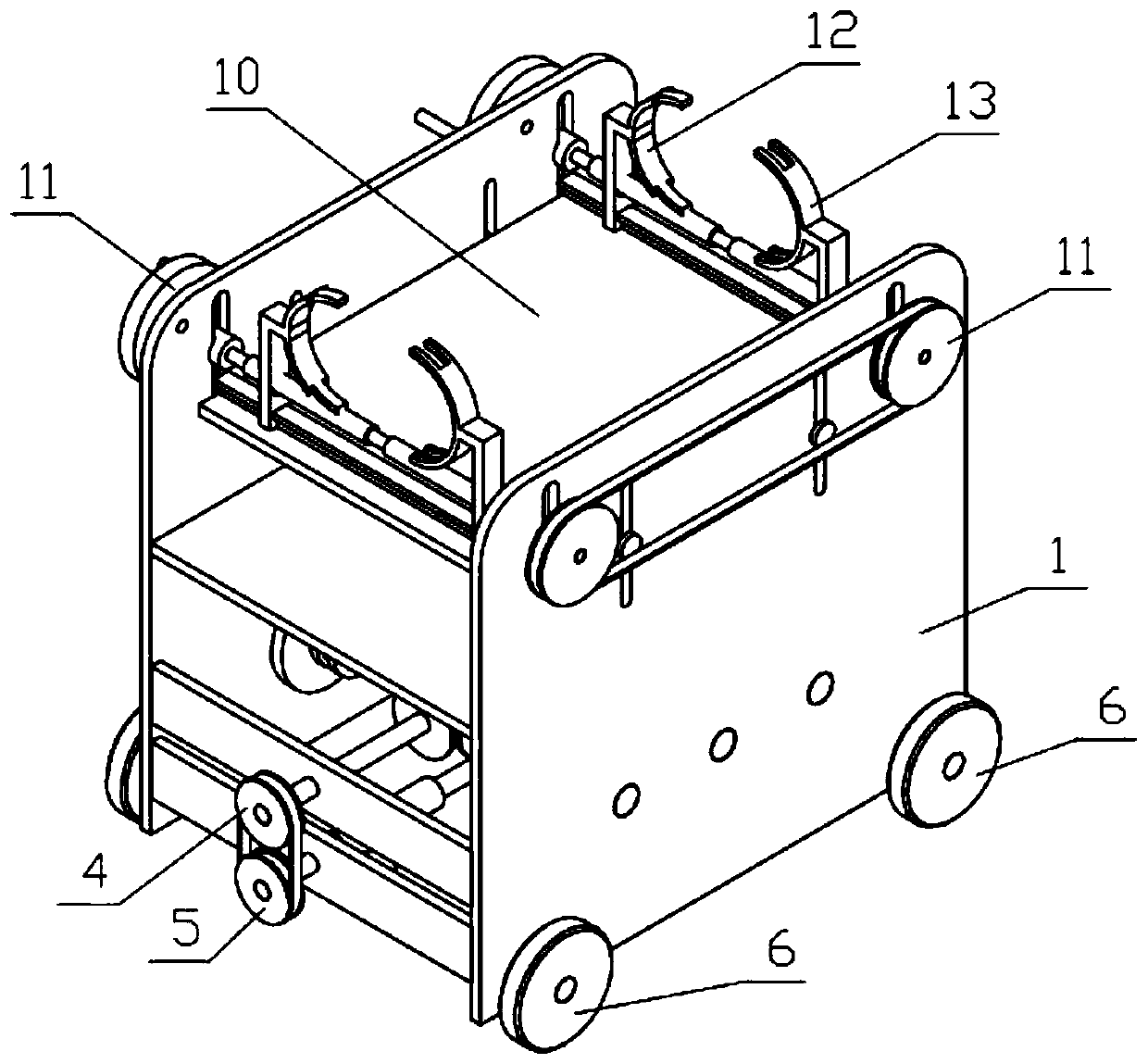

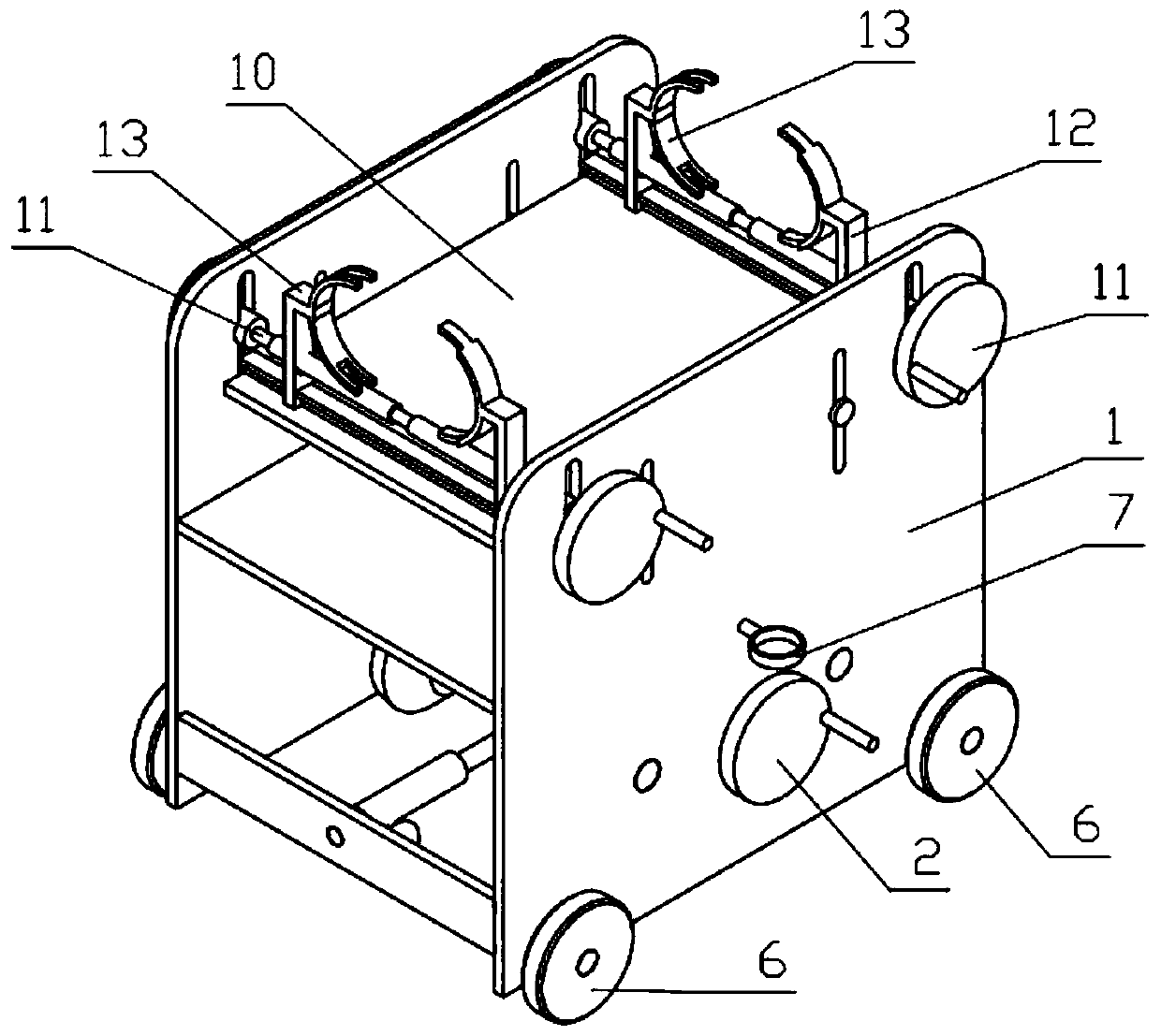

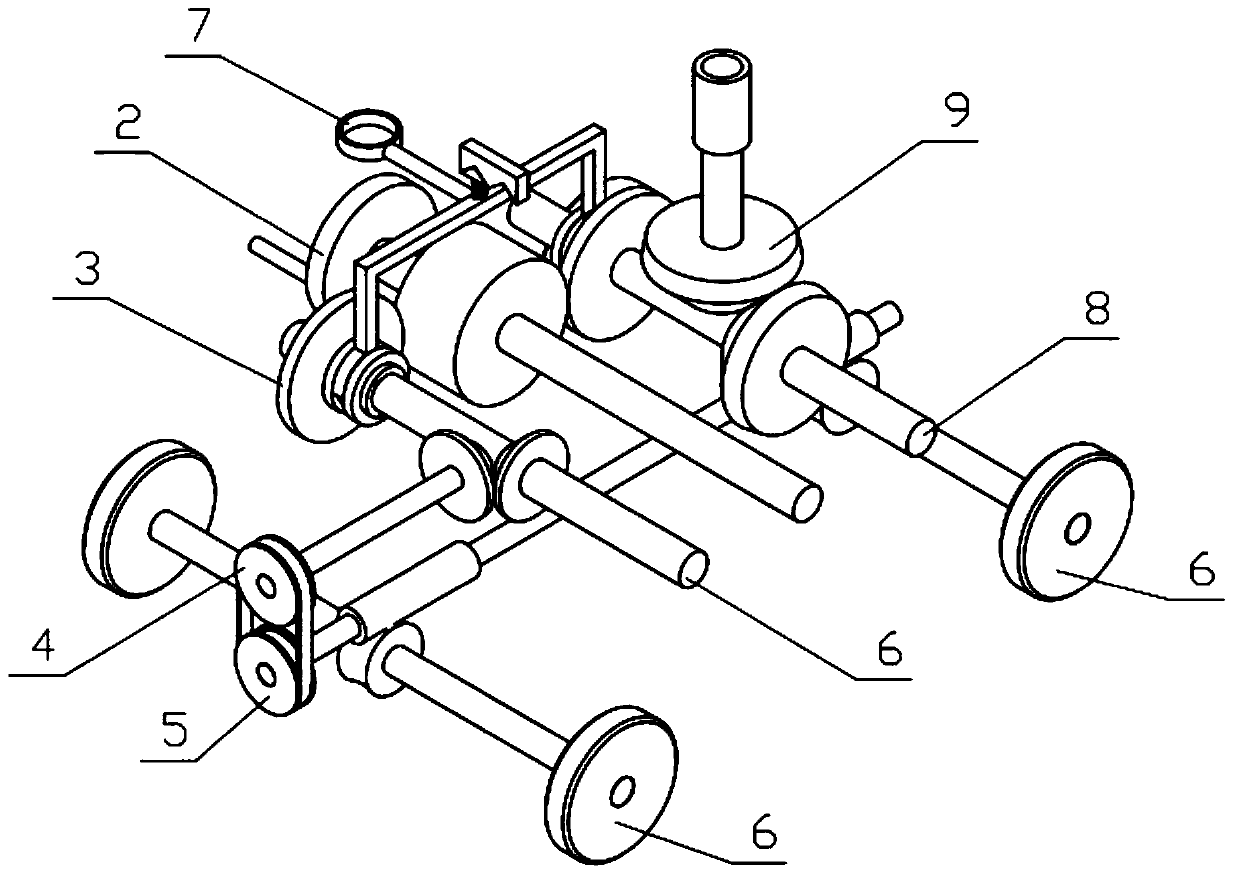

[0044] Combine below Figure 1-20 Description of this embodiment, a petroleum oil production pipeline frame, including the whole machine support 1, the power mechanism 2, the travel drive mechanism 3, the travel transmission mechanism 4, the drive axle 5, the control mechanism 7, the lifting drive mechanism 8, the lifting mechanism 9, the lifting mechanism Plate 10, clamping mechanism 11, clamping hand I12 and clamping hand II13, the power mechanism 2, travel driving mechanism 3, travel transmission mechanism 4, drive axle 5, travel mechanism 6, lifting drive mechanism 8 and lifting mechanism 9 are all Rotationally connected to the bracket 1 of the whole machine, the power mechanism 2 and the travel drive mechanism 3 are driven through gear meshing, the travel transmission mechanism 4 and the travel drive mechanism 3 are driven through gear meshing, and the travel transmission mechanism 4 and the drive axle 5 are connected through a belt transmission, and the walking There are...

specific Embodiment approach 2

[0046] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain Embodiment 1, the whole machine bracket 1 includes side plates 1-1, bottom plates 1-2, connecting plates 1-3, support plates 1-4, W-shaped clamping blocks 1 -5. Vertical sliding groove I1-6, vertical sliding groove II1-7 and circular through hole 1-8, two side plates 1-1 are symmetrically arranged on the left and right, and the two side plates 1-1 are fixedly connected There are bottom plates 1-2, two connecting plates 1-3 are symmetrically arranged front and back, the left and right ends of the two connecting plates 1-3 are respectively fixedly connected to the front and rear ends of the two side plates 1-1, and the supporting plates 1-4 The left and right ends of the two side plates 1-1 are fixedly connected to the front ends of the two side plates 1-1, the W-shaped block 1-5 is welded to the lower end of the bottom plate 1-2, and the front and rear ends of the upper sides of the...

specific Embodiment approach 3

[0048] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain the second embodiment, the power mechanism 2 includes a power shaft 2-1, a power handle 2-2 and a power gear 2-3, and the power handle 2-2 is fixedly connected to the power shaft At the left end of 2-1, the power gear 2-3 is fixedly connected to the middle end of the power shaft 2-1, and the two ends of the power shaft 2-1 are respectively connected to the two side plates 1-1 in rotation; when in use, manually turn the power handle 2-2, the power handle 2-2 drives the power shaft 2-1 to rotate, and the power shaft 2-1 drives the power gear 2-3 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com