A complete polishing machine and polishing method for automatic tool change

A technology of automatic tool change and complete machine, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of time-consuming and laborious, low productivity, low efficiency of workpiece polishing, etc., and achieve reduction Small size, increased productivity, and improved polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

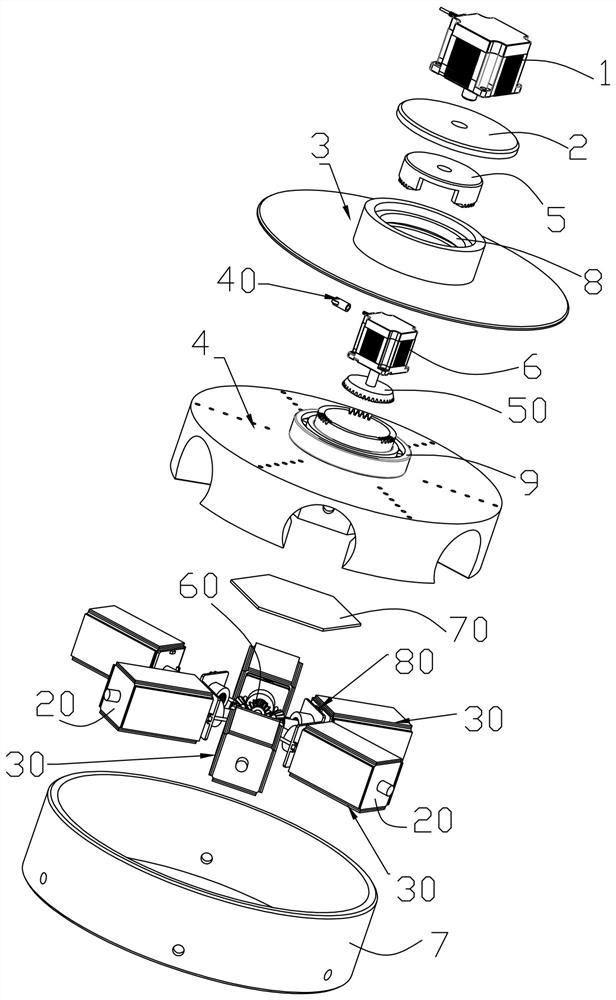

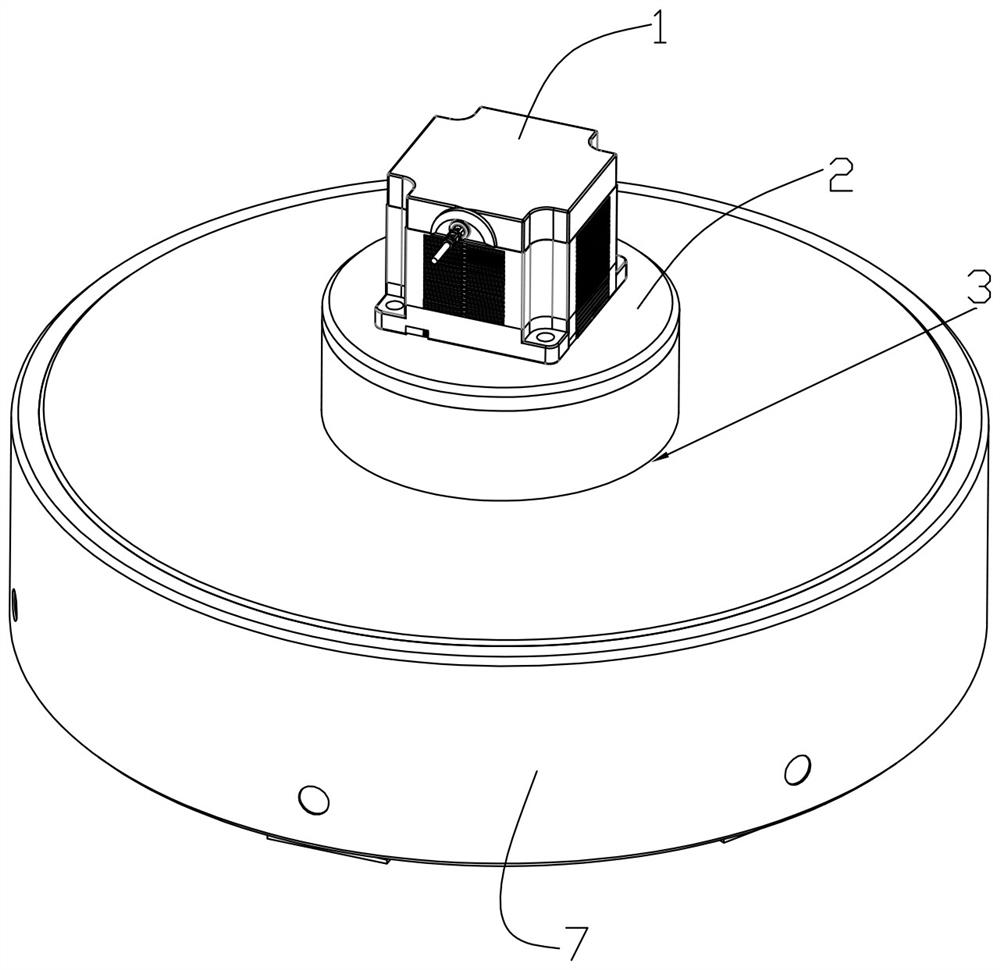

[0031] Such as Figure 1 to Figure 14 As shown, a polishing machine with automatic tool change described in this embodiment includes a storage table for placing objects to be polished, and a boom is arranged above the storage table; a polished structure.

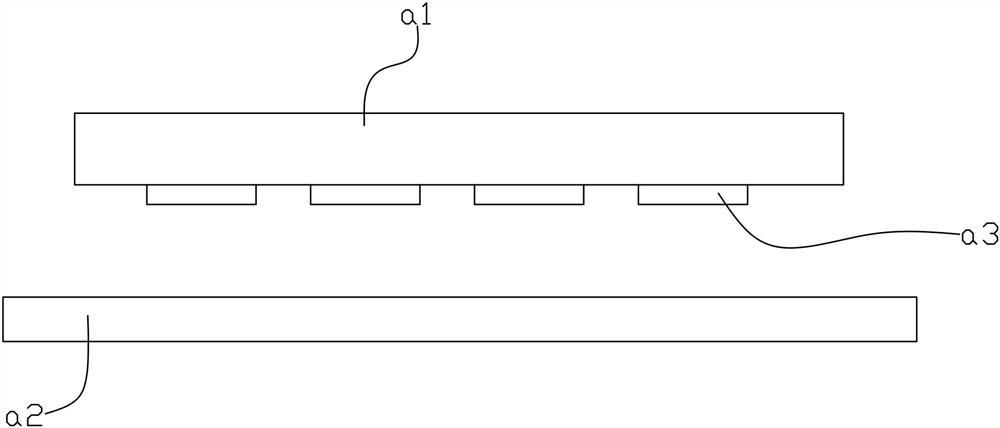

[0032] The polishing structure a3 includes a grinding drive motor 1, a motor mounting plate 2, a dust collection cover 3, a main turntable 4, an end face gear 5, a tool change drive motor 6 and an outer support ring 7, and the dust collection cover 3 includes a set Dust cover 31 and cover base connecting pipe 32, the lower end of the cover base connecting pipe 32 passes through the middle part of the dust collecting cover 31, and is integrally formed with the dust collecting cover 31, the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com