Push-pull type straight row tool magazine

A technology of push-pull and tool magazine, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of cost increase, large quantity, large volume, etc., achieve the effect of volume reduction, tool change function, and large processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

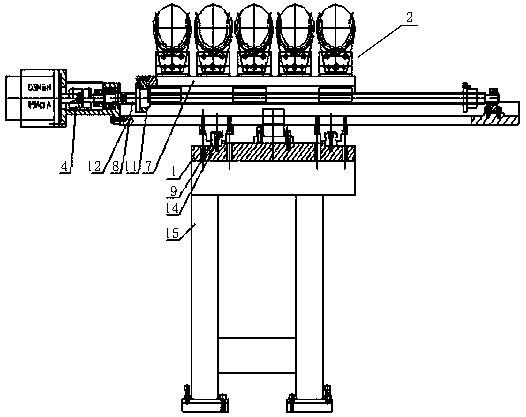

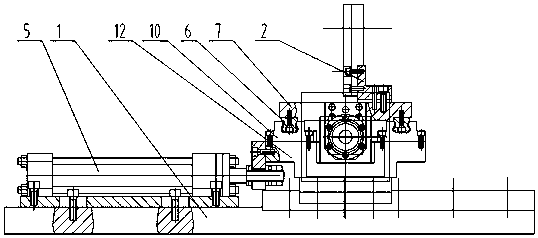

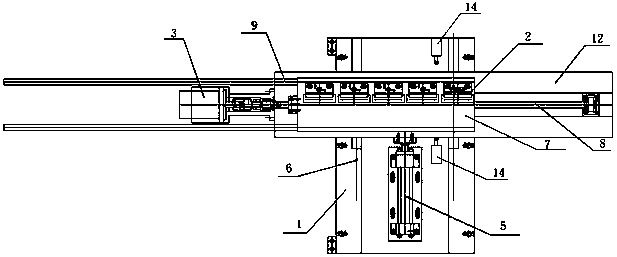

[0015] A push-pull straight row tool magazine, such as Figure 1-3 As shown, including the tool base 2, a plurality of tool bases are installed side by side on the first pallet 7, the bottom of the first pallet 7 is fixed with the first linear guide rail 6, and the first linear guide rail 6 paired with the first The slider 10 is fixed on the second supporting plate 12, the ball screw 8 is fixed on the second supporting plate 12, and the screw nut 13 paired with the ball screw 8 is fixed on the bottom of the first supporting plate 7 , the ball screw 8 is connected with the drive motor 3 through a coupling 4;

[0016] The bottom of the second pallet 12 is equipped with a second slider 14 paired with the second linear guide rail 9, and the second linear guide rail 9 is perpendicular to the first linear guide rail 6 and fixed on the tool magazine body 1; A hydraulic cylinder 5 is also fixed on the tool magazine body 1 , and the hydraulic cylinder 5 is fixedly connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com