Automatic stamping control system and method for printing terminal documents

A printing terminal and control method technology, applied to printing devices, printing, typewriters, etc., can solve problems such as large workloads, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

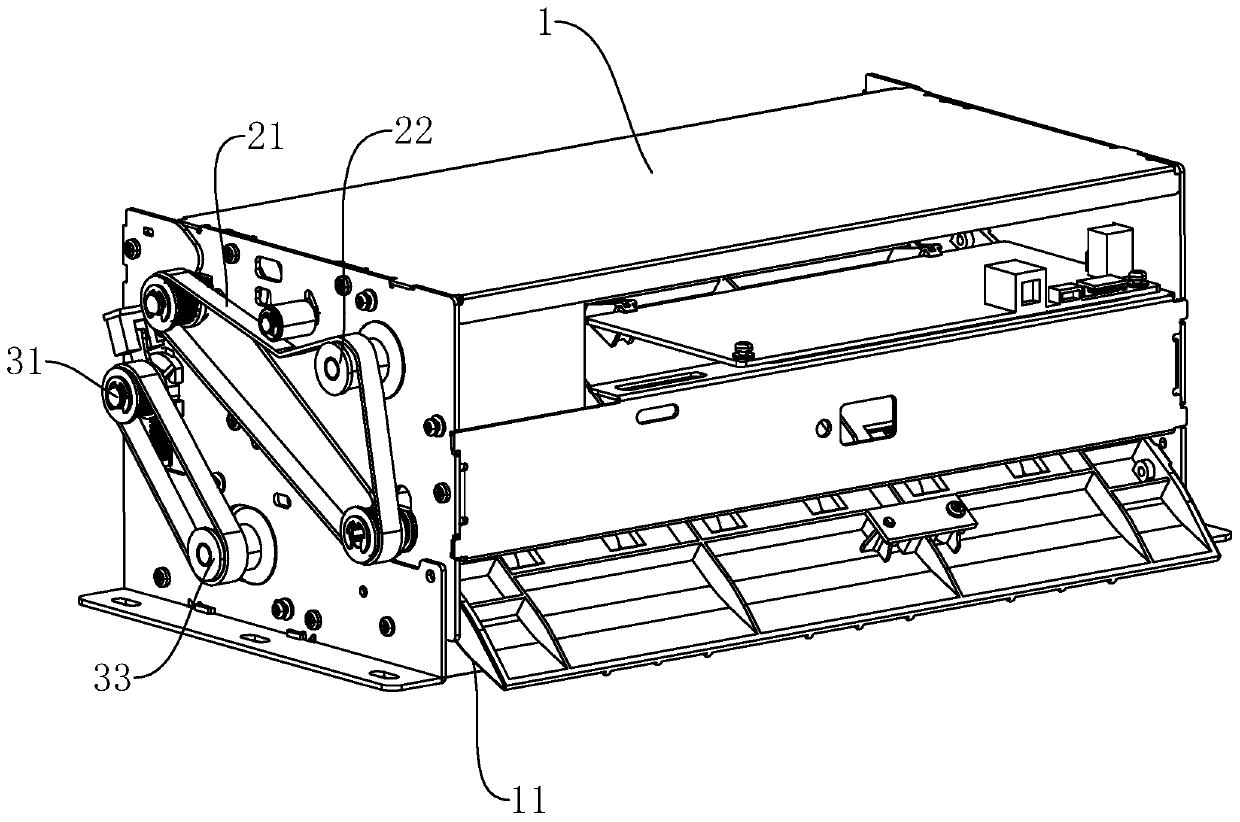

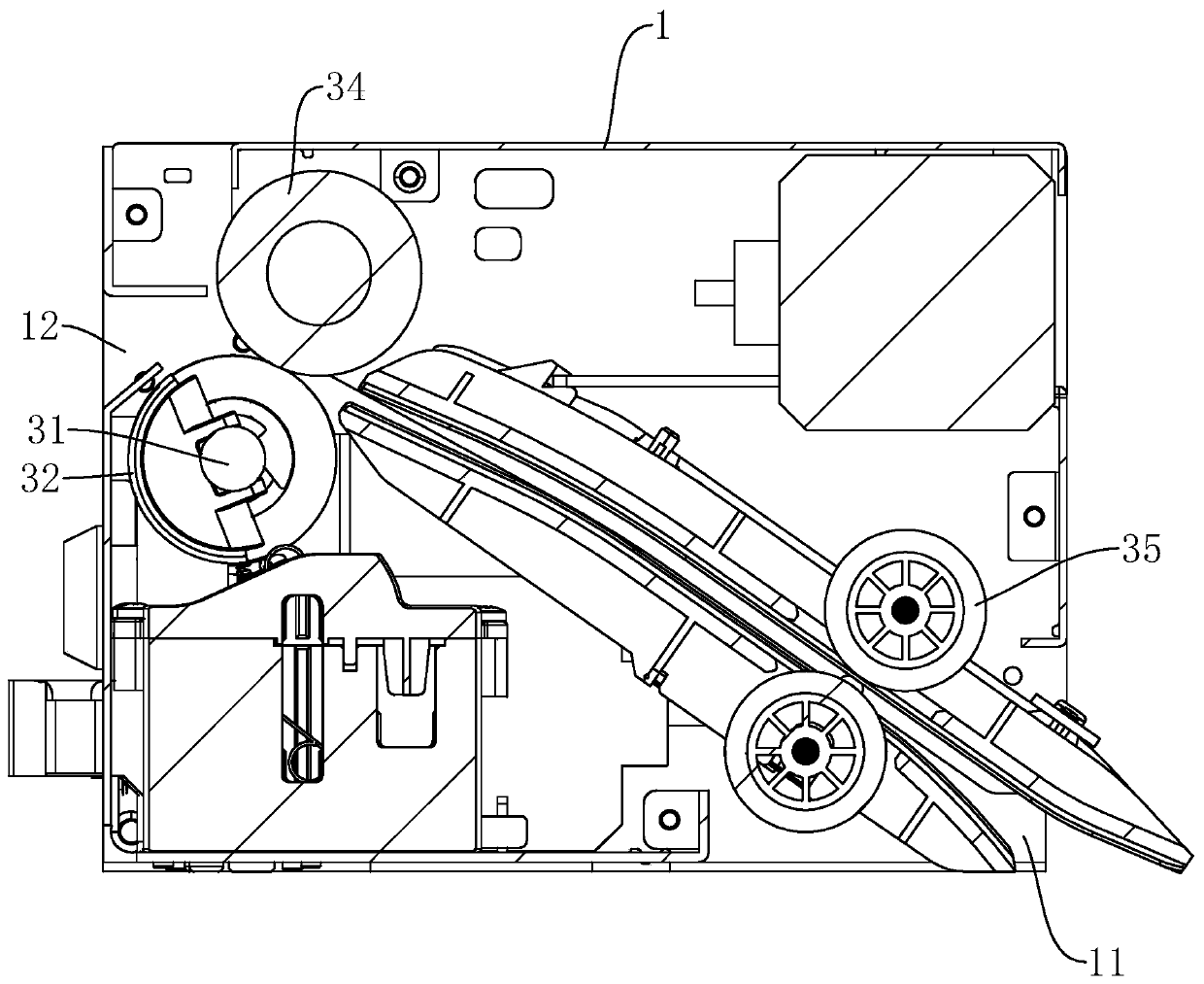

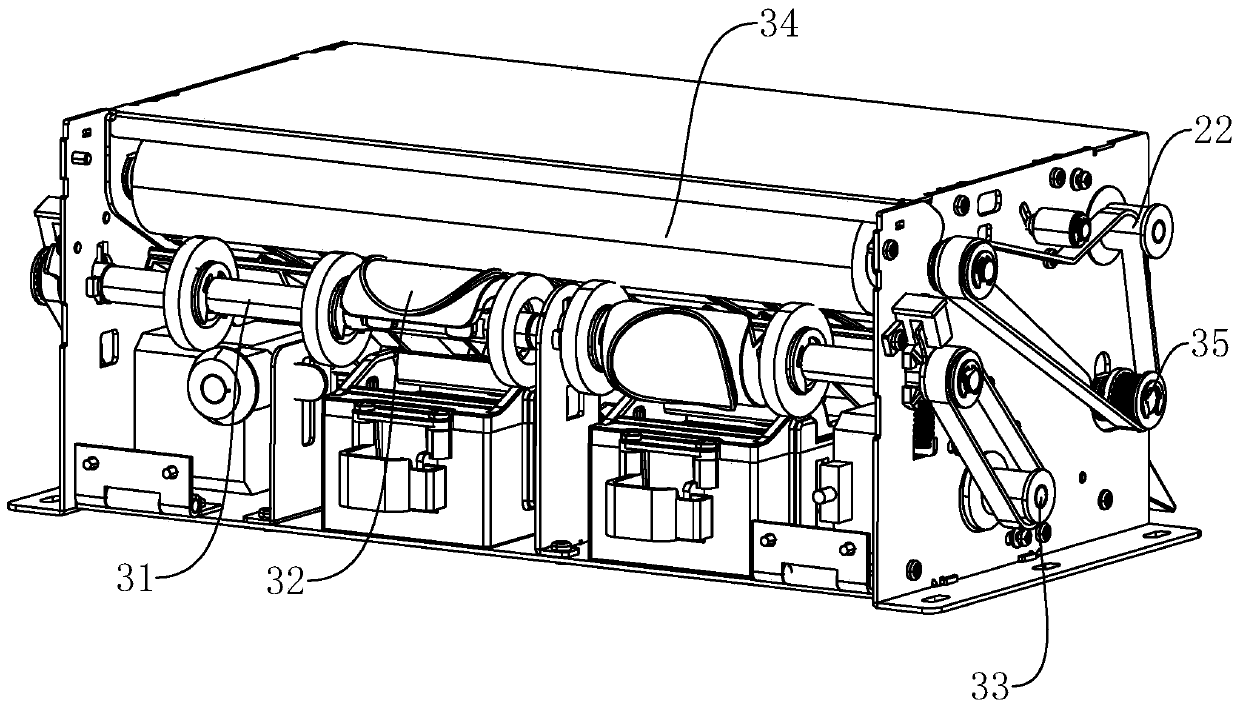

[0024] The invention discloses a printing terminal document automatic seal control system, referring to figure 1 , figure 2 and image 3 , including a casing 1, on which a paper inlet 11 and a paper outlet 12 are arranged. The casing 1 is placed on a matching printer, and the paper inlet 11 on the casing 1 is facing the paper outlet of the printer, so that the paper is sent from the printer into the paper inlet 11 by the short-distance driving force of the printer. The housing 1 is provided with a paper guiding mechanism near the paper inlet 11 to convey the paper to the paper outlet 12, and the housing 1 is provided with a stamping mechanism near the paper outlet 12 and sending the paper out of the paper outlet.

[0025] A sensor for sensing paper entering the casing 1 is fixed at the paper inlet 11, and the sensor is connected to a programmable logic controller, ie, a PLC, through wires. In this embodiment, the sensor may be a photoelectric sensor, and when the photoelec...

Embodiment 2

[0030] The invention discloses a control method for automatic stamping of a printing terminal document. Firstly, the short-distance driving force of the printer is used to send paper from the printer into the paper inlet 11. After the sensor detects the arrival of the paper, a trigger signal is sent to a programmable logic controller. . After the programmable logic controller receives the trigger signal sent by the sensor, it triggers the first drive mechanism 33 and the second drive mechanism 22 to start respectively, and the first drive mechanism 33 and the second drive mechanism 22 drive the rotating shaft 31, the platen roller 34 and the guide The paper roll 35 rotates. The paper guide roller 35 transmits the paper to the pressing roller 34, the paper enters between the pressing roller 34 and the rotating shaft 31, and the stamp 32 contacts the paper to complete the stamping.

[0031] Input constants in the programmable logic controller by computer, including the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com