Mobius type heat exchanger

A technology of heat exchanger and Us type, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., which can solve the problems of easy accumulation of debris in pipelines, failure of heat exchanger, and easy damage of heat exchanger equipment and other problems, to achieve the effects of not easy to accumulate sundries, high heat exchange efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

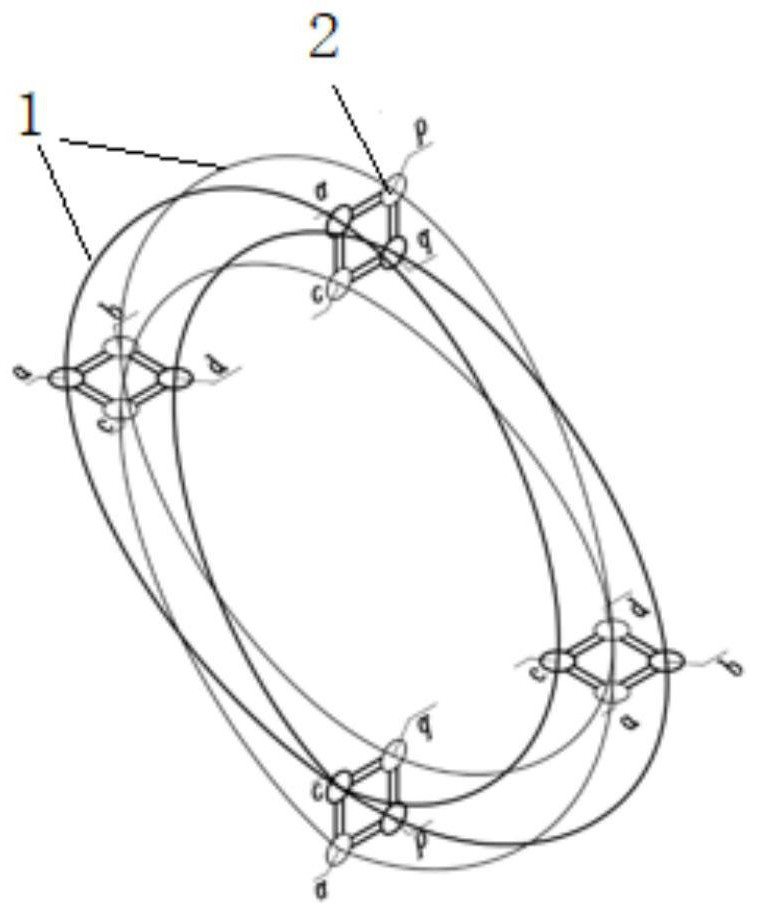

[0029] Such as figure 1 As shown, the Mobius type heat exchanger of the present invention adopts the Mobius strip principle and geometric model, and the Mobius strip principle and geometric model were developed by German mathematician Mobius (Mobius, 1790~1868) and John Listing discovered in 1858.

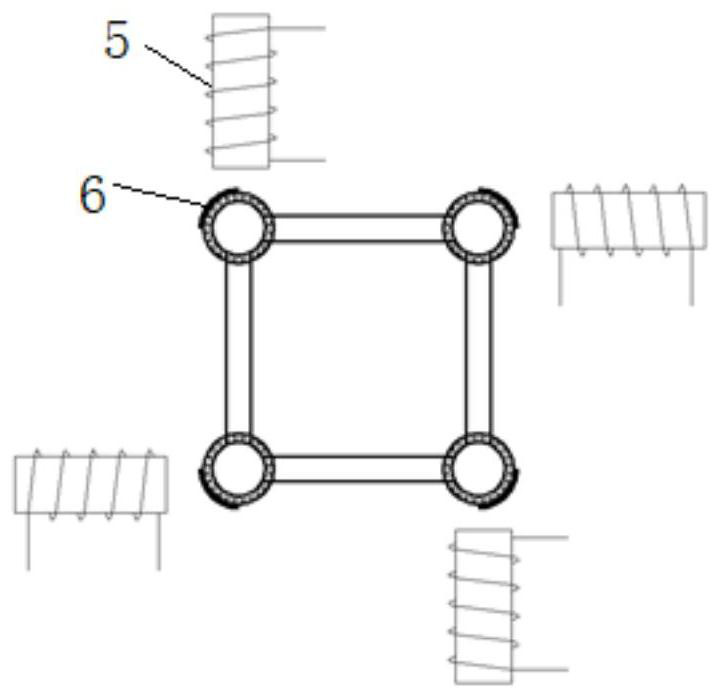

[0030] The heat exchanger includes pipes and connector sets. The pipe is composed of two bundles of mutually independent heat exchange pipes 1, and the two bundles of mutually independent heat exchange pipes 1 are respectively connected to a connector group 2, and the connector group 2 is composed of four mutually connected connectors. The four connectors are respectively connector a, connector b, connector c, and connector d.

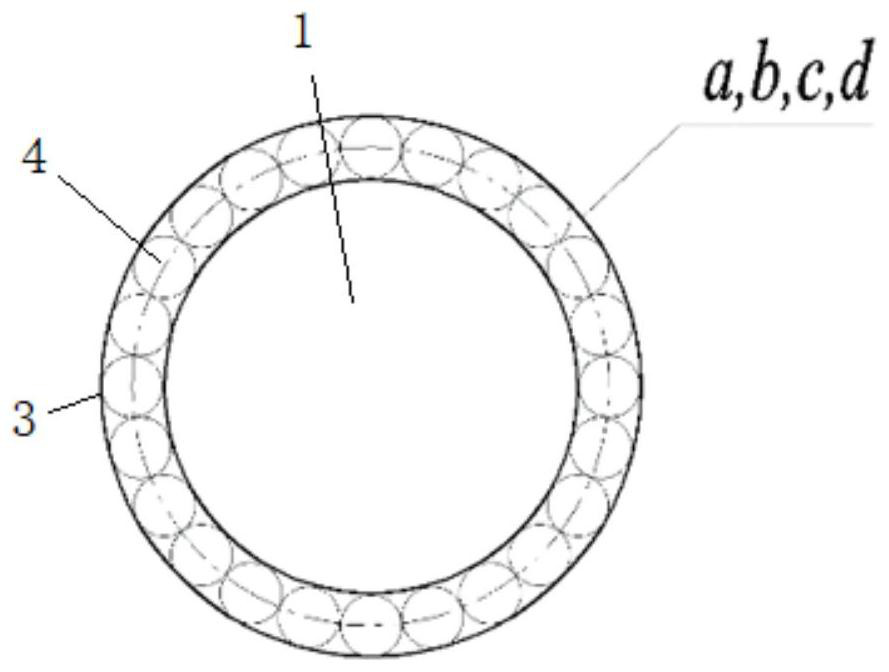

[0031] Such as figure 2 As shown, the outside of the connector is a rotatable pipe 3, the inside is a fixed heat exchange pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com