a tricycle

A technology of three-wheel trolleys and wheels, which is applied in the direction of belts/chains/gears, transmission devices, components with teeth, etc., and can solve the problems of inability to complete adaptive automatic torque conversion, increased trolley running distance, and large movement resistance, etc. problems, to achieve the effect of flexible and light movement, increased adhesion, and less axial movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The directions shown in the accompanying drawings are up, down, left, and right.

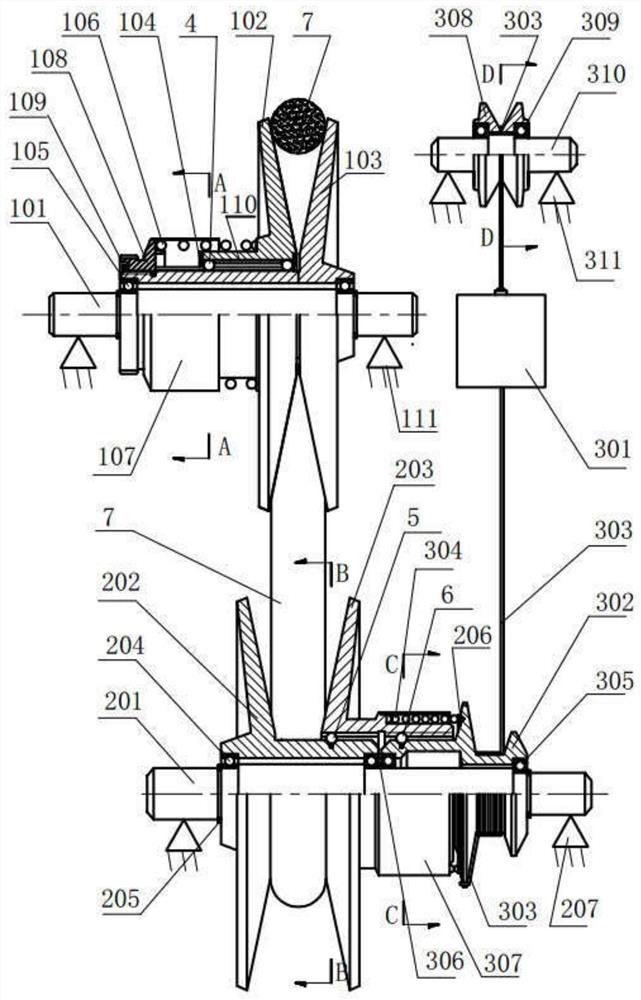

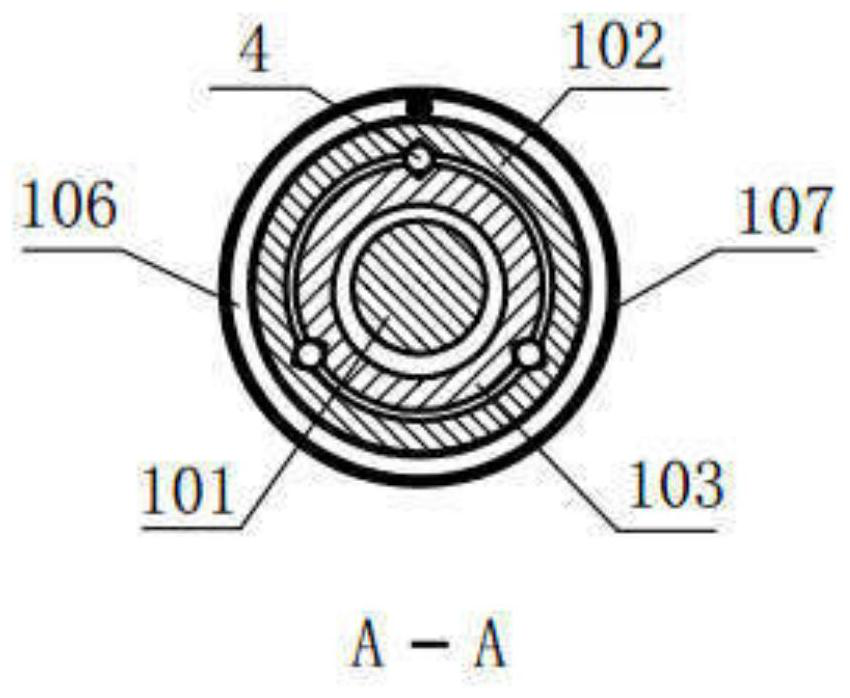

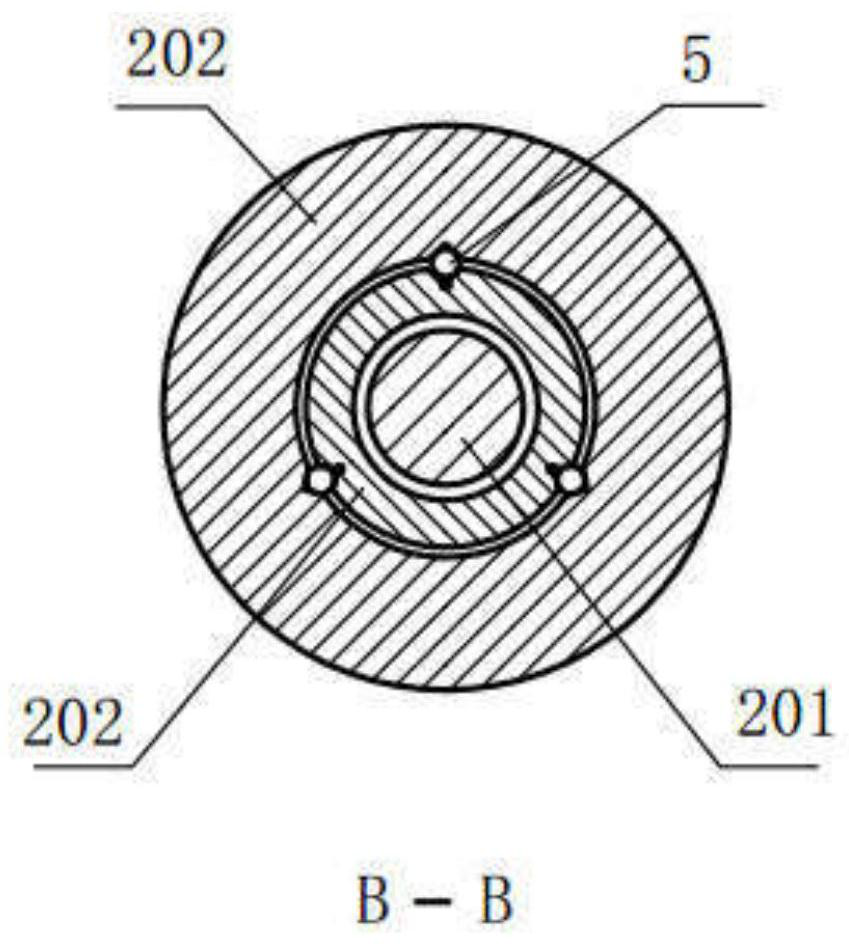

[0027] Such as Figure 1-3 As shown, the carbon-free tricycle consists of three parts: driven mechanism 1, active mechanism 2 and control mechanism 3. The two ends of the inner hole of the right driven wheel sheet 103 are provided with bearing seat holes, and are installed on the outer diameter of the driven wheel shaft 101 middle part through the driven wheel bearing 105, so that the movement is unimpeded. The driven wheel shaft 101 is connected to the driven shaft bracket 111 . According to the principle of three-point fixed circle, at the two ends of the inner hole of the left driven wheel 102, two sets (each group of three of the same specification) of the first steel balls are arranged in 4 equal parts at the outer diameter of the middle part of the right driven wheel 103. Gear 108 sets small spring 106 on the outer diameter of left driven wheel sheet 102 left end, respectively pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com