Aluminum alloy embedded slotted ceiling board structure and installation method

A technology for ceiling panels and aluminum alloys, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of complex installation structure and process, waste of manpower and time, and reduce the quality of hoisting, so as to achieve fast installation speed, cost reduction, Avoid the effects of manual punching operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to more clearly illustrate the embodiments of the present invention and the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the affiliation related to the orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

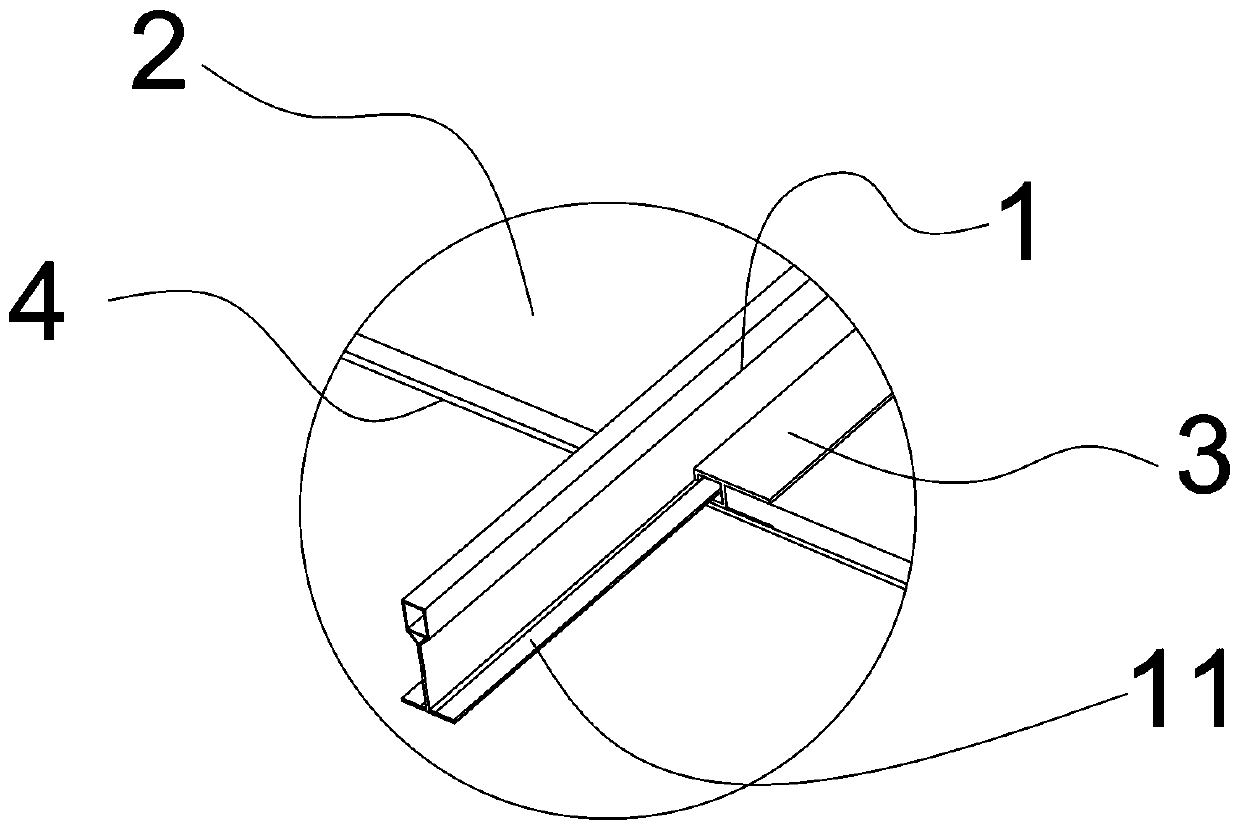

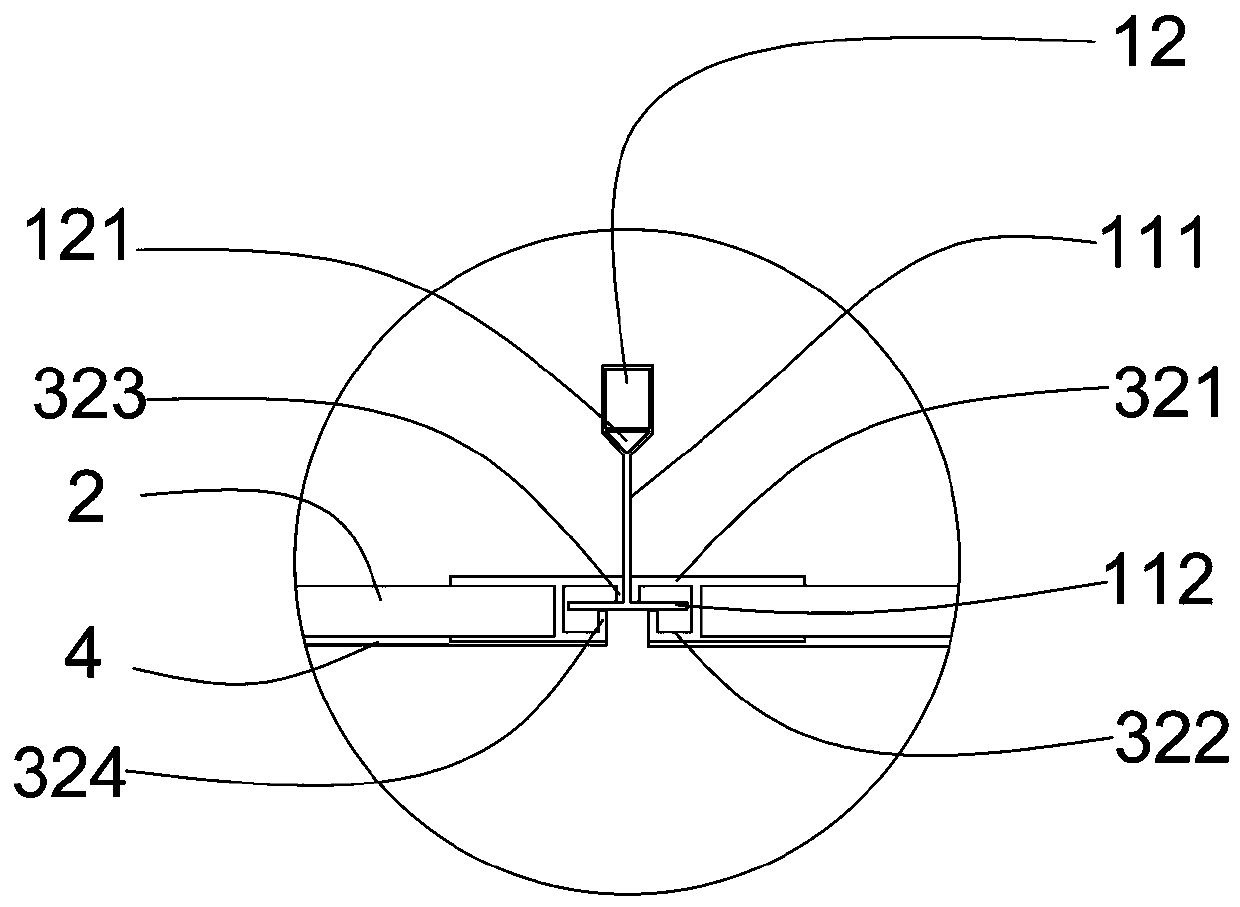

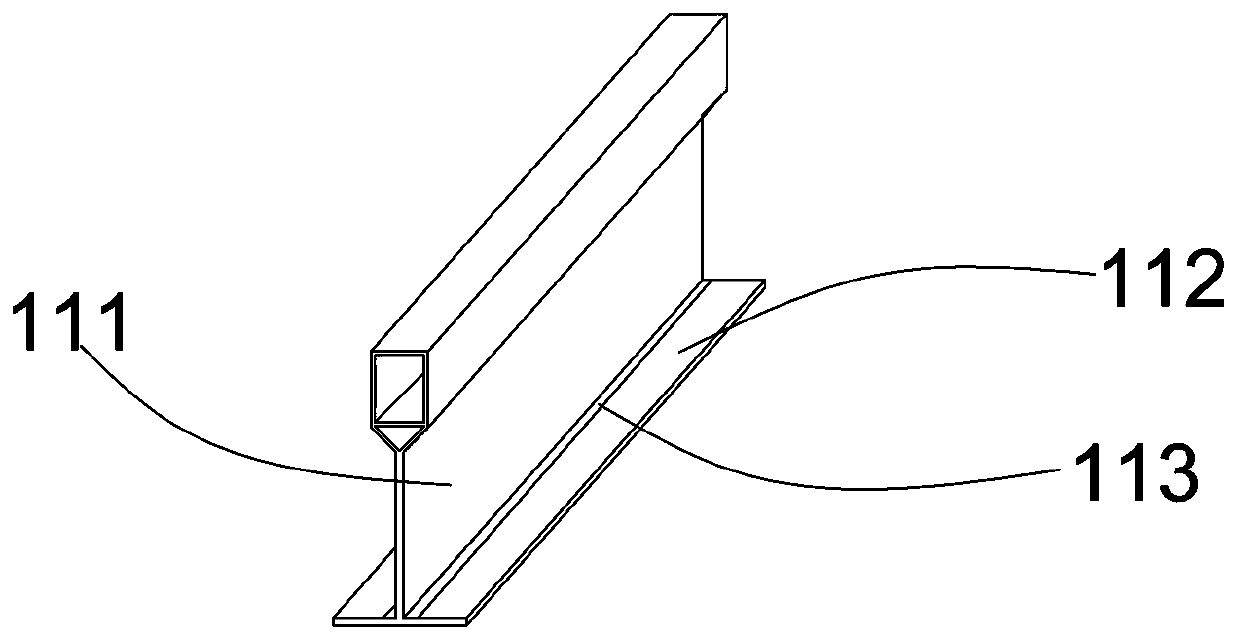

[0028] see figure 1 , figure 2 , image 3 with Figure 4 . An aluminum alloy embedded grooved ceiling panel 2 structure according to an embodiment of the present invention includes a keel 1 and a roof panel 2, and also includes a card insert 3 with one end buckled on one side of the top panel 2 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com