Multi-gradient quantitative alcohol blending bottle

A multi-gradient, alcohol technology, applied in mixer accessories, dissolving, mixer and other directions, can solve the problems of inability to guarantee the accuracy of preparation, large demand for gradient alcohol, labor workload of medical staff, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

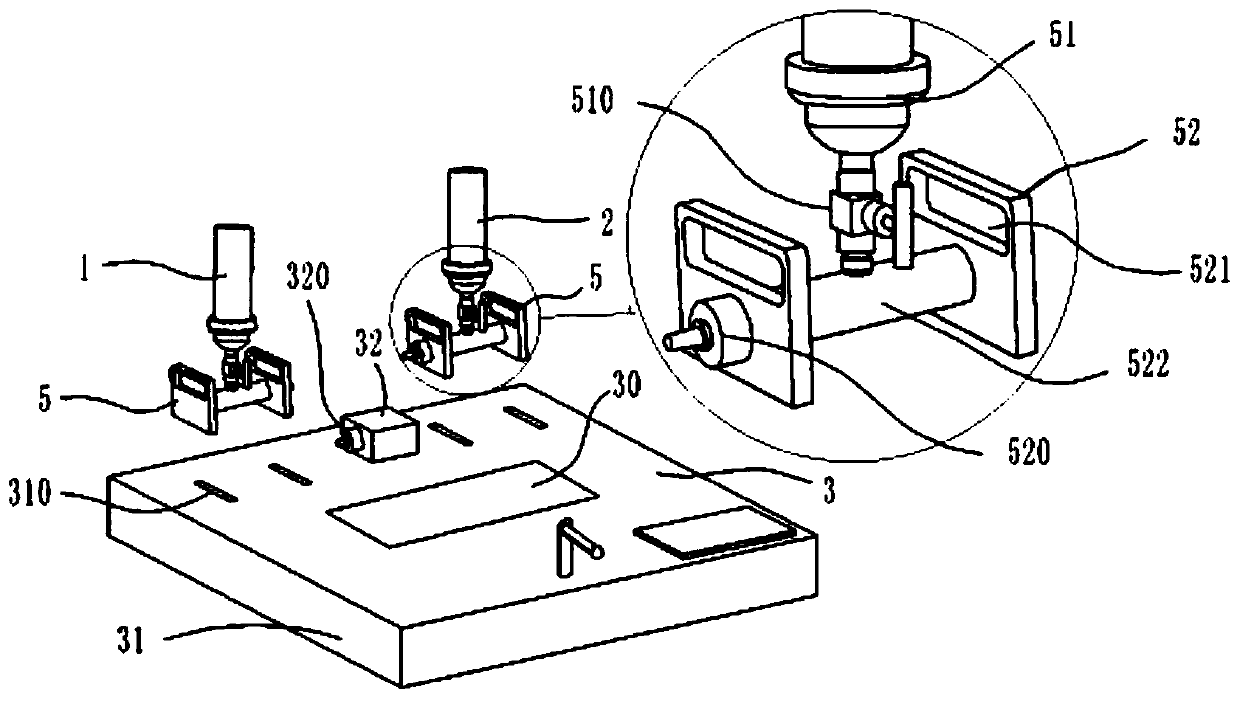

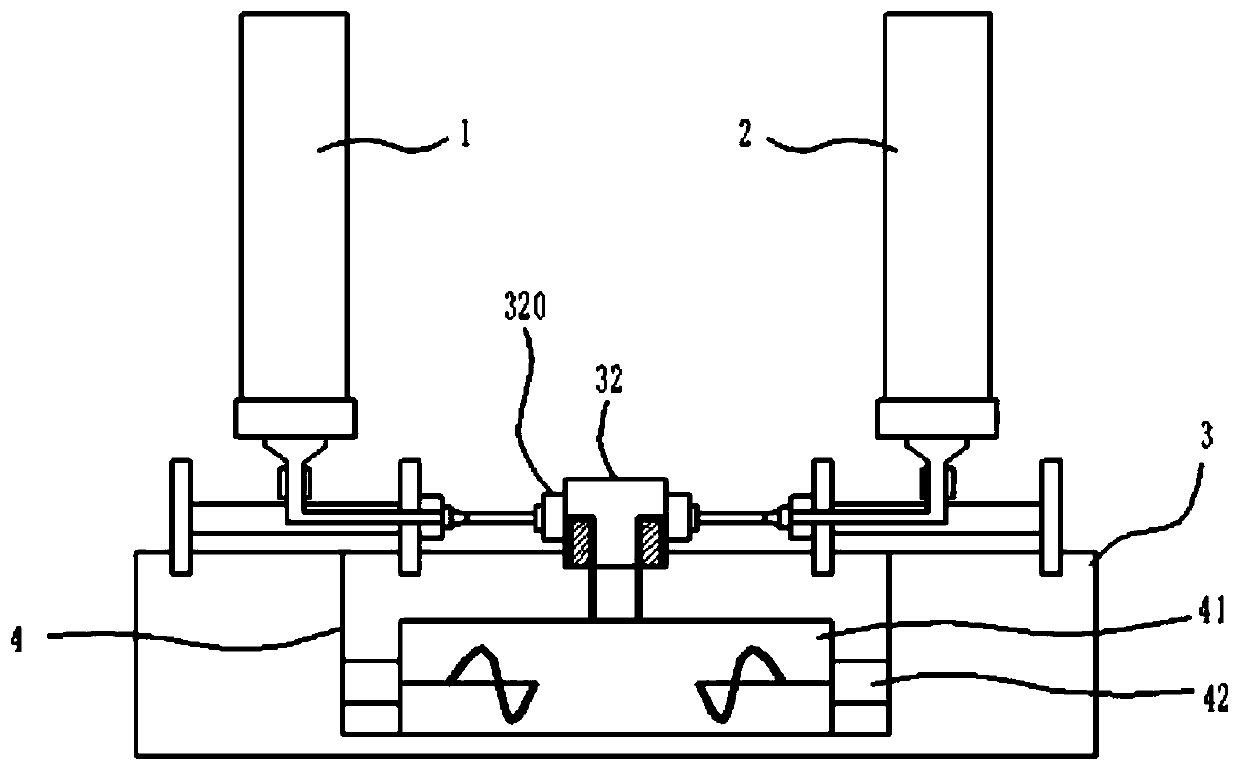

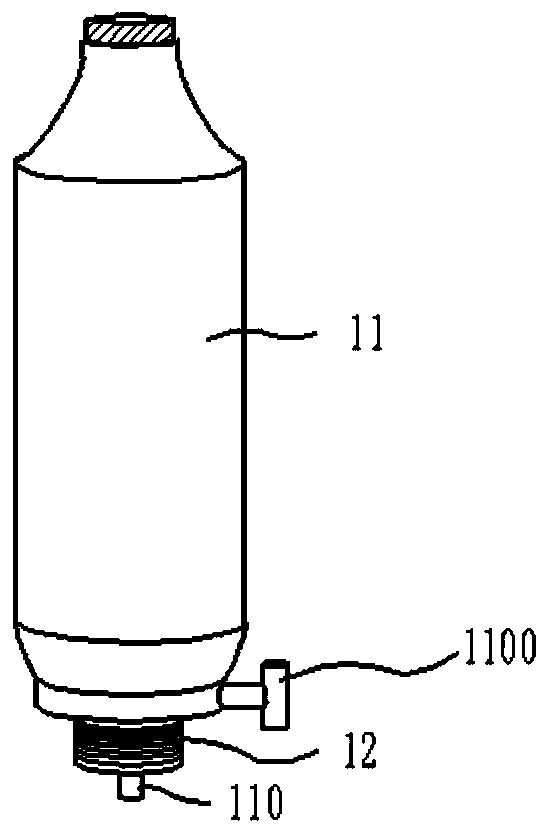

[0032] Embodiment 1: as figure 1 The shown multi-gradient alcohol quantitative preparation bottle includes a first preparation bottle 1 for holding alcohol, a second preparation bottle 2 for holding water, and preparation components for preparing alcohol with different gradient concentrations; The preparation assembly includes a base case 3, a mixing chamber 4 arranged inside the base case 3, a connecting assembly 5 for connecting the mixing chamber 4 and the first preparation bottle 1 and the second preparation bottle 2, and a control device for controlling;

[0033] The base box 3 includes a base box body 31, and a mounting seat 32 arranged on the base box body 31;

[0034] The connecting mixing chamber 4 includes a mixing chamber body, a mixing bottle 41 arranged inside the mixing chamber body, and a stirring device 42 arranged inside the mixing chamber body; the inside of the mixing bottle 41 is provided with a drain for discharging mixed alcohols of different gradient con...

Embodiment 2

[0043] Embodiment 2: Different from Embodiment 1: as Figure 5 As shown, it also includes a suitcase body 6, the base box 3 is embedded in the suitcase body 6, and the suitcase body 6 is provided with slots for placing the first preparation bottle 1, the second preparation bottle 2, and the connection assembly 5.

[0044] When in use, it can be carried to any area for use through the suitcase body 6 .

Embodiment 3

[0045] Embodiment 3: different from Embodiment 1: as Figure 6 As shown, the connection mixing chamber 4 also includes a five-way 43; there are three mixing bottles 41 and three stirring devices 42, each mixing bottle 41 corresponds to one stirring device 42, and each mixing bottle 41 is provided with a liquid discharge pump ; The five ports of the five-way port 43 are respectively connected with two second mounting heads 320 and three mixing bottles 41, and the connection between the five-way port 43 and the three mixing bottles 41 is provided with a solenoid valve.

[0046] When in use, alcohols of different concentrations can be prepared through three mixing bottles 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com