Raw gas high-temperature residual heat recovery method and device

A waste heat recovery device and waste heat recovery technology are applied in the discharge device of dry distillation gas, steam generation method using heat carrier, steam superheating and other directions, which can solve the waste of high-quality waste heat resources of waste gas, no heat of waste gas, and hidden dangers of production safety. and other problems, to achieve high-quality and high-efficiency waste heat recovery and utilization, improve reliability and safety, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

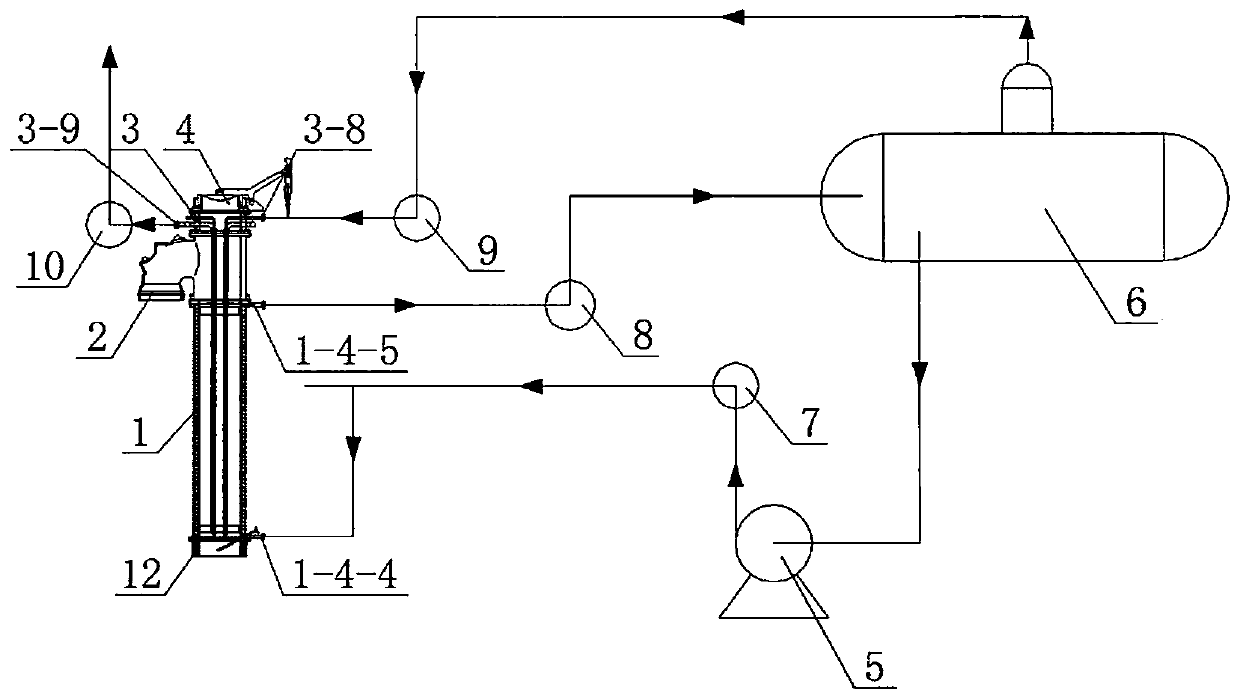

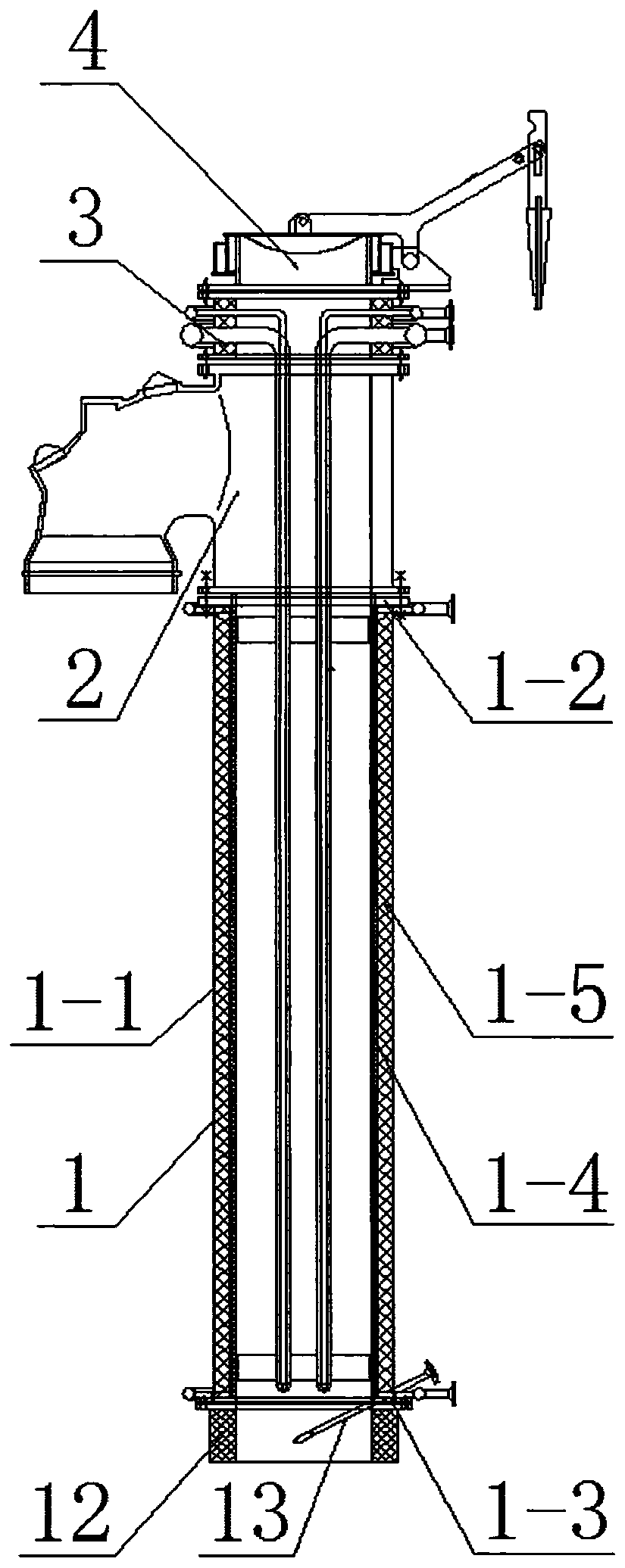

[0077] Example 1: Production of superheated steam by using high temperature waste heat of raw gas

[0078] The present invention relates to a method for producing superheated steam by using high-temperature waste heat of raw coal gas, said method comprising the following steps:

[0079] The raw coal gas from each carbonization chamber of the coke oven is respectively passed into the raw gas circulation channels of the respective waste heat recovery risers. , the raw gas in the raw gas channel of the rising pipe performs heat exchange with the heat extractor on the wall of the rising pipe and the heat extractor inside the rising pipe respectively, the water inlet of the circulating water pump is connected with the steam drum, and the circulating water is pumped out The water inlet is connected to the main water supply pipe, and the main water supply pipe sends water to the water inlet of the pipe wall heat extractor of each rising pipe wall heat extractor through multiple paral...

Embodiment 2

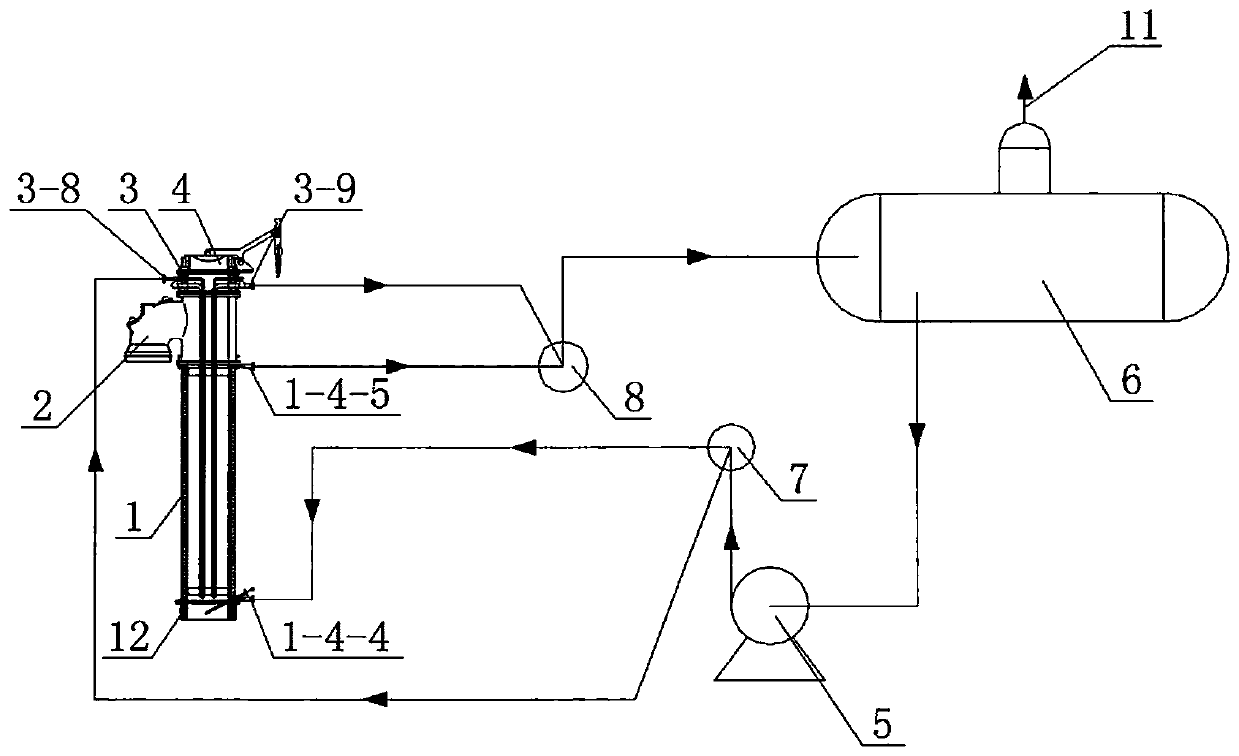

[0083] Example 2: Maximize the production of saturated steam by utilizing the high temperature waste heat of raw gas

[0084] The present invention relates to a method for maximizing the production of saturated steam by utilizing high-temperature waste heat of raw coal gas, the method comprising the following steps:

[0085] The raw coal gas from each carbonization chamber of the coke oven is respectively passed into the raw gas circulation channels of the respective waste heat recovery risers. , the raw gas in the raw gas channel of the rising pipe performs heat exchange with the heat extractor on the wall of the rising pipe and the heat extractor inside the rising pipe respectively, the water inlet of the circulating water pump is connected with the steam drum, and the circulating water is pumped out The water outlet is connected to the main water supply pipe, and the main water supply pipe sends water to the water inlet of the pipe wall heat extractor of each riser pipe wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com