Low-temperature exhaust heat recovery type lithium bromide absorption type cold and hot water system

A waste heat recovery and low-temperature waste heat technology, applied in adsorption machines, energy-saving heating/cooling, refrigerators, etc., can solve problems such as inability to heat and concentrate lithium bromide solution, increase investment in waste heat recovery systems, and complicate waste heat recovery systems, so as to save heating Wide range of heat exchangers and low-temperature waste heat, saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

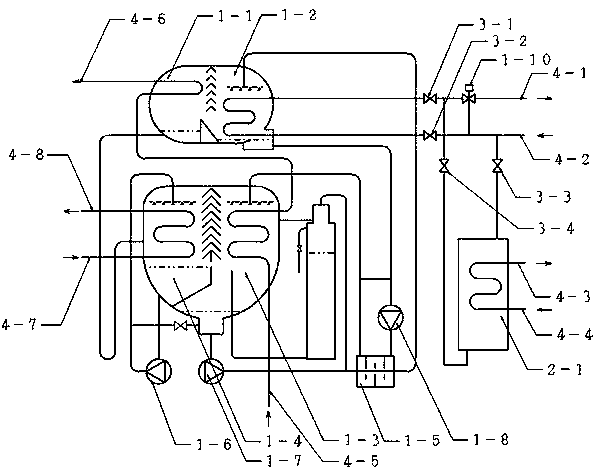

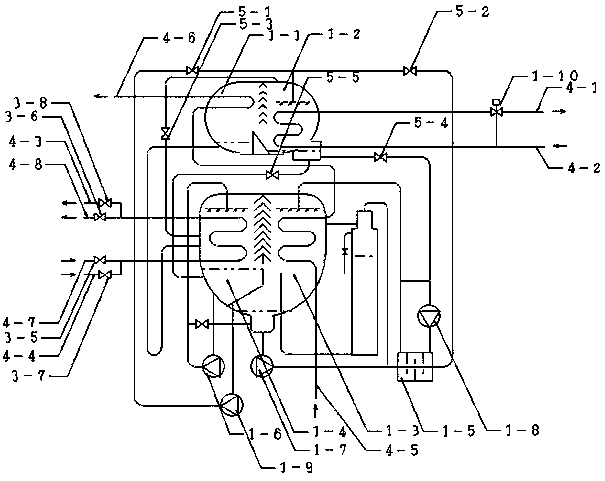

[0021] Such as figure 2 Shown is a flow chart of a low-temperature waste heat recovery lithium bromide absorption cold and hot water system of the present invention, the system is mainly composed of the following components: condenser 1-1, waste heat recovery device 1-2, absorber 1-3, Evaporator 1-4, internal heat recovery device 1-5, refrigeration evaporation circulation pump 1-6, dilute solution circulation pump 1-7, concentrated solution circulation pump 1-8, heating evaporation circulation pump 1-9, waste heat control valve 1 -10. Water system cooling and heating switching valve 3-5~3-8, waste heat outlet pipeline 4-1, waste heat inlet pipeline 4-2, heating outlet pipeline 4-3, heating inlet pipeline 4-4, cooling water Inlet pipeline 4-5, cooling water outlet pipeline 4-6, cold water inlet pipeline 4-7, cold water outlet pipeline 4-8, system internal cooling and heating switching valve 5-1~5-5, air extraction system, control System and connecting pipelines, valves, etc. ...

Embodiment 2

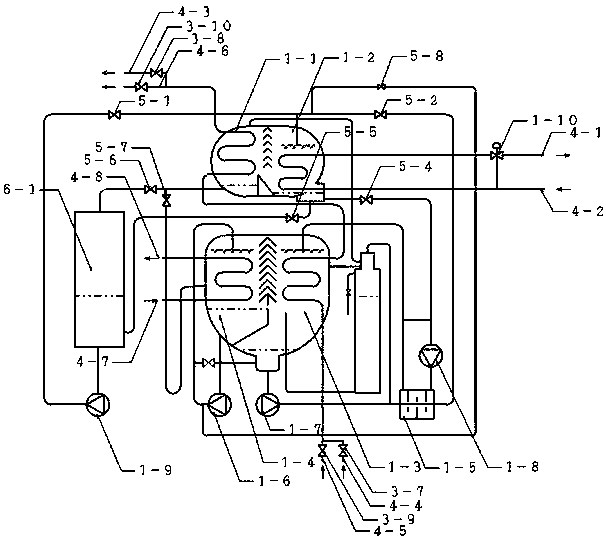

[0025] Such as image 3 Shown is another low-temperature waste heat recovery lithium bromide absorption type cold and hot water system flow chart of the present invention. Compared with the previous scheme, the refrigerant storage 6-1 is added. When the water system cooling and heating switching valve 3-7~3-8 close, water system cooling and heating switch valve 3-9~3-10 open, system internal cooling and heating switching valve 5-1, 5-5, 5-6, 5-8 close, system internal cooling and heating switching valve 5-2, 5-4, 5-7 turn on and switch the control mode to carry out the waste heat recovery refrigeration operation mode, the operation mode is basically the same as the previous scheme, and will not be repeated. When the cooling and heating switching valves 3-7~3-8 of the water system are opened, the cooling and heating switching valves 3-9~3-10 of the water system are closed, and the cooling and heating switching valves 5-1, 5-5, 5-6, and 5-8 inside the system are opened , The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com