Test tool for multi-plunger type pipeline assembly

A multi-plunger, plunger-type technology, applied in the testing of machine/structural components, fluid tightness testing, measuring devices, etc., can solve the problems of increasing the shape calibration process, inconvenient operation of the test, and troublesome operation, etc. Achieve the effect of reducing the deformation of the pipeline, eliminating the calibration process, and facilitating the test operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

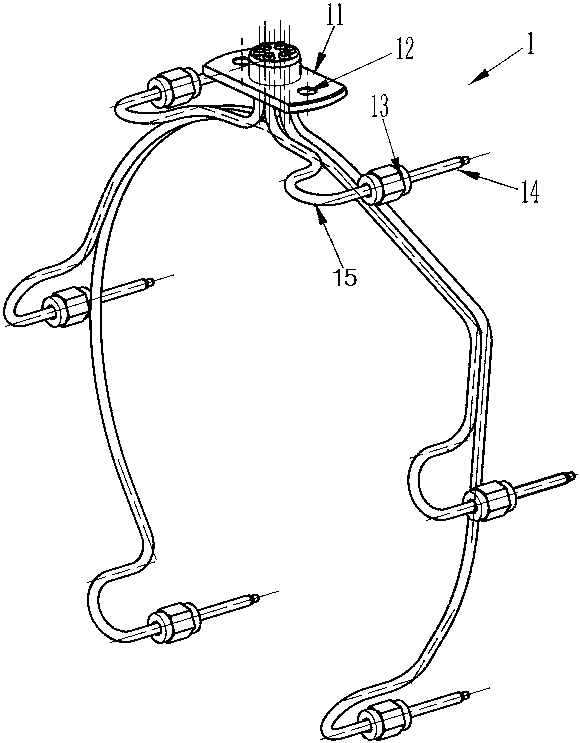

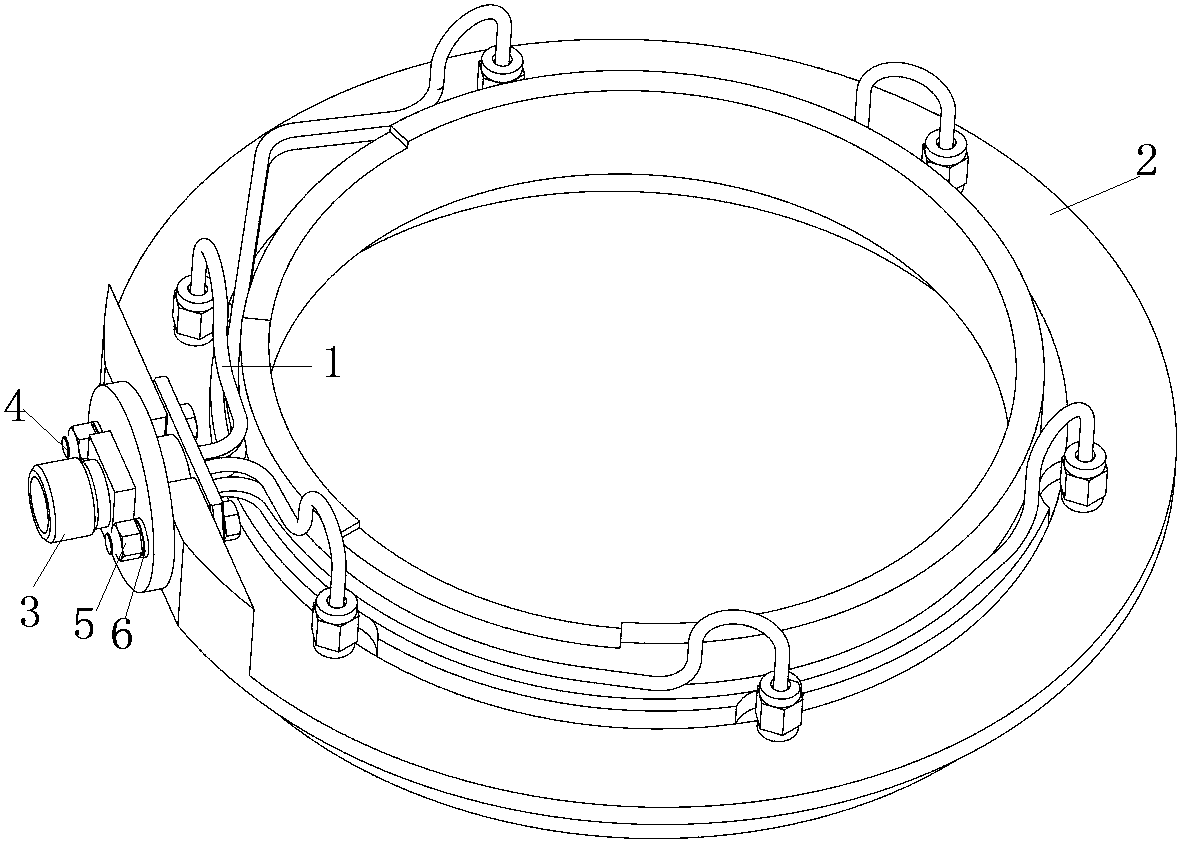

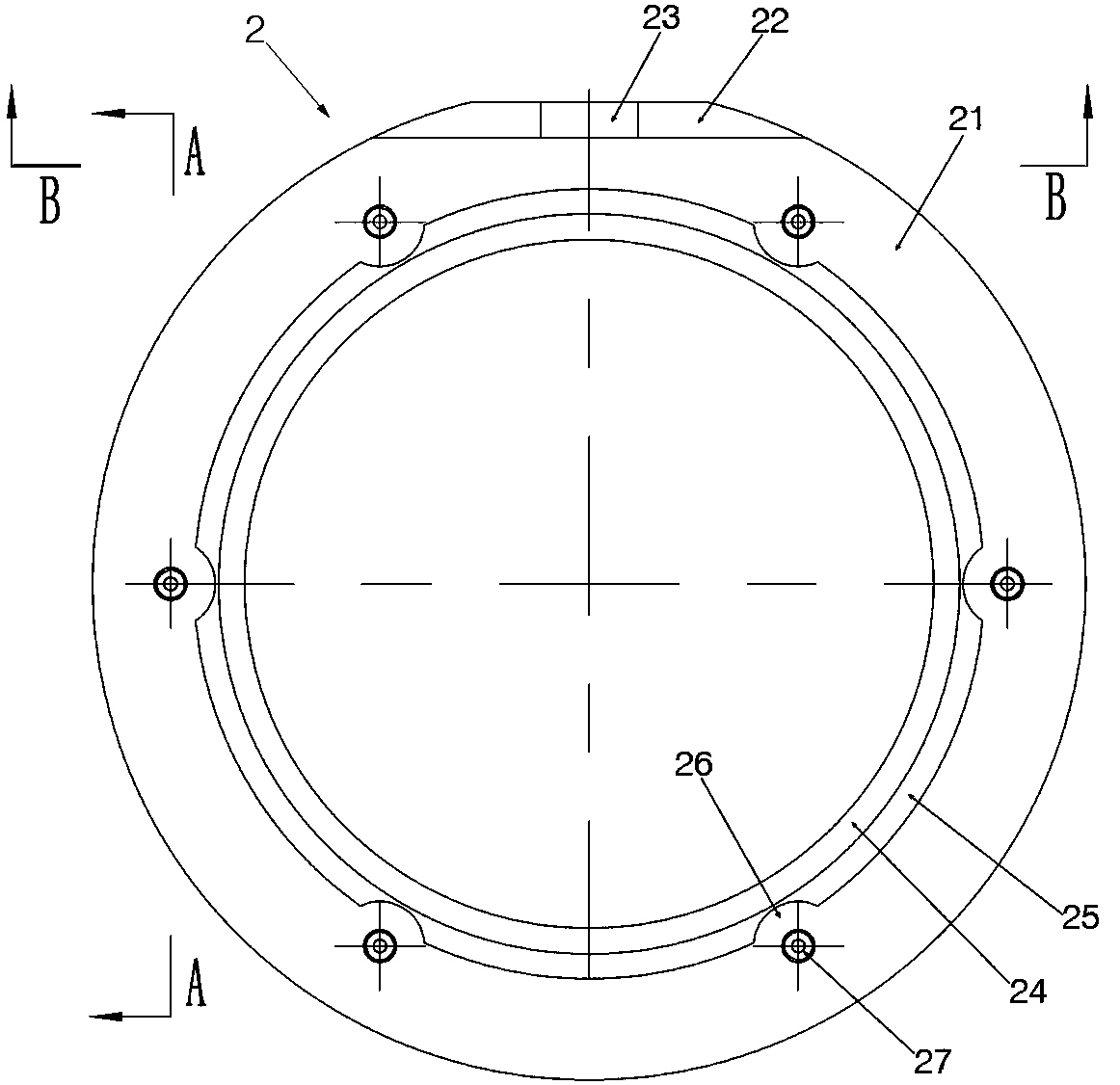

[0024] An embodiment of the test tooling (hereinafter referred to as the test tooling) of the multi-plunger pipeline assembly in the present invention is as follows: figure 2 and image 3 As shown, the positioning seat 2 is included, and the positioning seat 2 includes a ring-shaped positioning seat body 21. The top surface of the positioning seat body 21 is provided with a positioning platform 22. The positioning platform 22 has two parallel sides inside and outside, combined with Figure 5 As shown, the positioning platform 22 is provided with a U-shaped groove 23 with an open upper end, and the positioning platform 22 is also provided with connecting holes 29 on both sides of the U-shaped groove 23 .

[0025] Such as figure 2 and image 3 As shown, the top surface of the positioning seat body 21 is provided with a positioning cylinder 24 coaxial with the positioning seat body 21 , and a support platform 25 is provided at the bottom of the positioning cylinder 24 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com