Automobile engine cover hinge assembly tool and assembling method thereof

A technology of automobile engine and engine cover, which is applied in the direction of motor vehicles, transportation and packaging, etc., and can solve the problems of not being able to realize the size correlation of engine cover hinges, poor assembly stability, and large accumulation of manufacturing tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

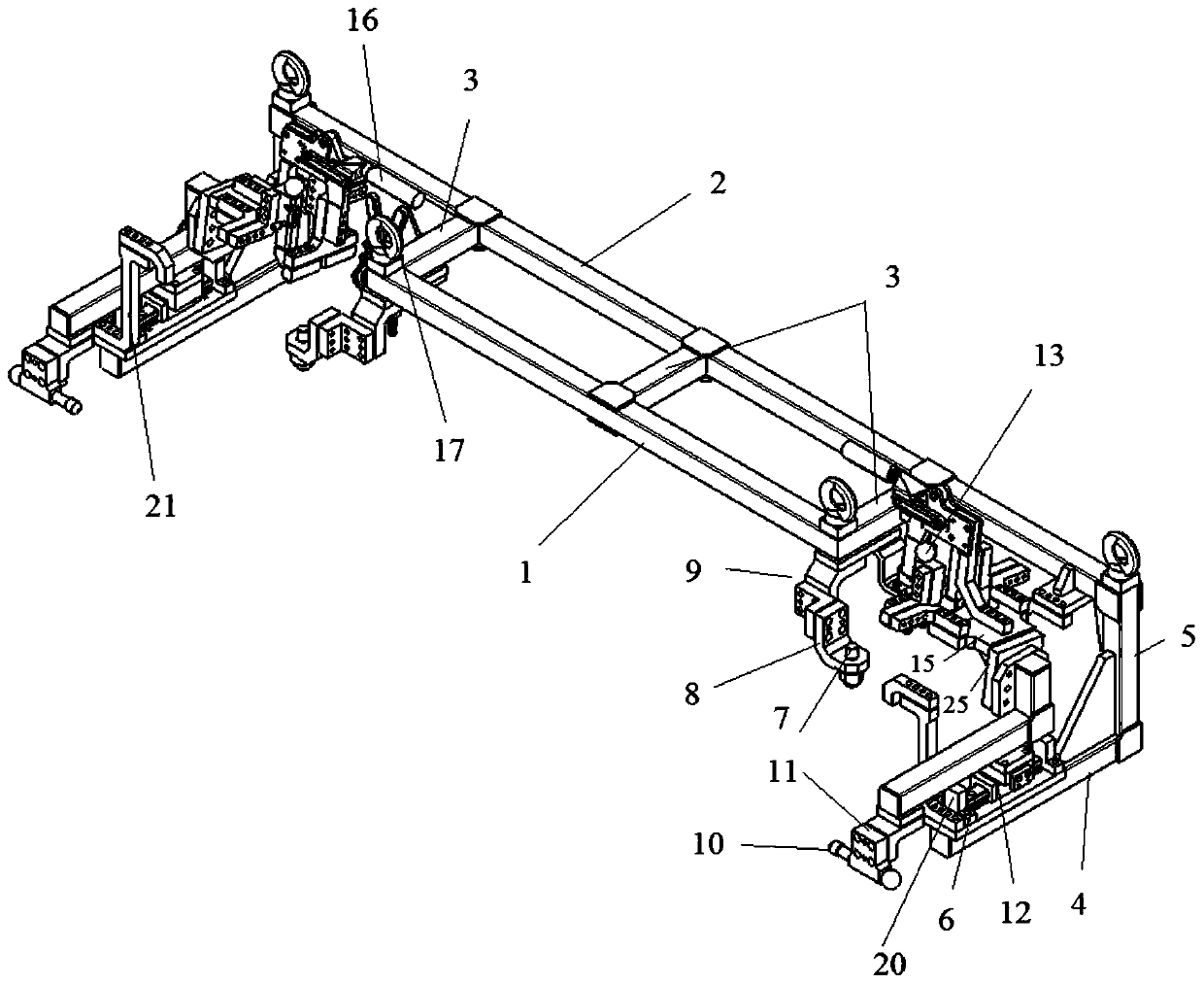

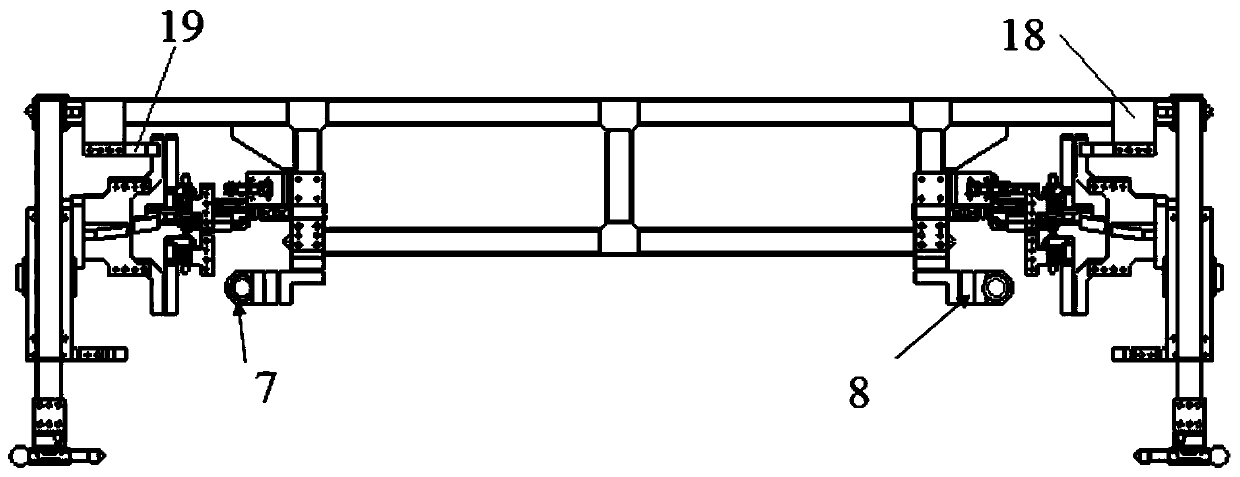

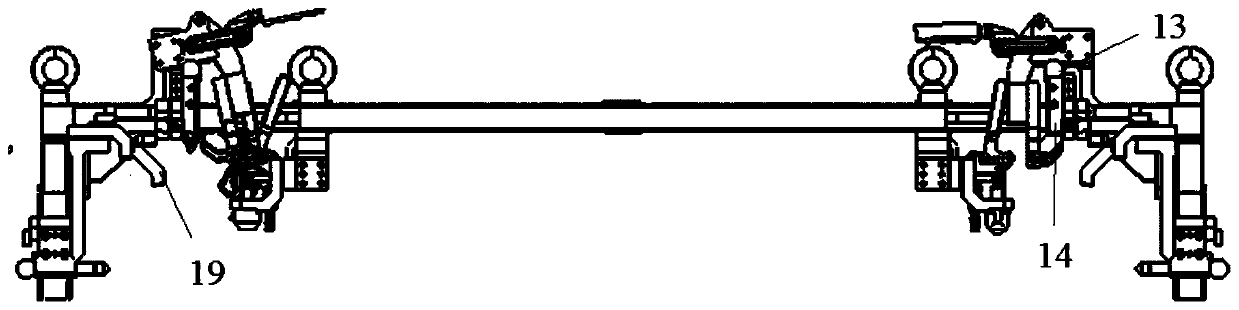

[0033] Such as Figure 1-4 As shown, an automobile engine cover hinge assembly, the assembly is axisymmetrically distributed, including a bracket body, the bracket body is a double-layer frame, including an upper bracket and a lower bracket, and a pair of first positioning unit and a supporting unit are arranged on the upper bracket , the lower bracket is provided with a pair of second positioning units that can move along the length direction of the vehicle body, the second positioning unit is fixedly connected with the third positioning unit, the first positioning unit is used for positioning the device on the vehicle body frame, and the supporting unit is used for positioning The fitting is supported on the body frame, the second positioning unit is used to align the fitting on the main positioning hole of the side wall of the body frame, and the third positioning unit is used to position the hinge on the body frame.

[0034]Wherein, the separate structure of the stent body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com