Cable winding and unwinding container and transport vehicle with same

A technology for containers and transport vehicles, which is applied to the field of cable retracting and transporting vehicles, can solve the problems of troublesome operation, prone to failures, and limited length of cables to be wound up, and achieves the effects of convenient operation, fewer joints, and less later failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

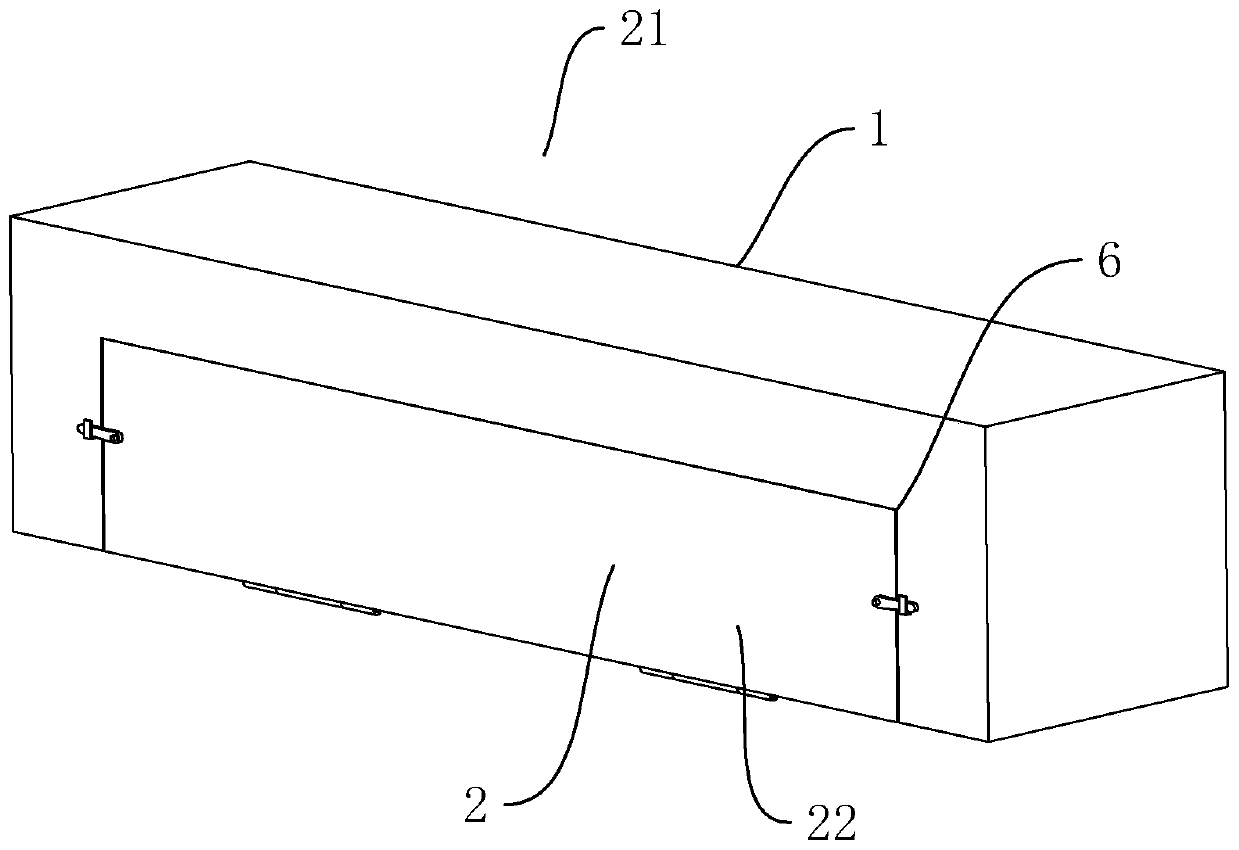

[0036] refer to figure 1 , is a cable retractable container 21 disclosed by the present invention, comprising a box body 1, an opening 6 is opened on one side of the box body 1, and a hinge plate 22 is hinged at the opening 6 of the box body 1, and the hinge plate 22 can be used In the sealing opening 6, the hinged plate 22 end near the bottom side of the box body 1 is hinged with the box body 1, and the hinged plate 22 is turned up and fixed with the box body 1 with a lock.

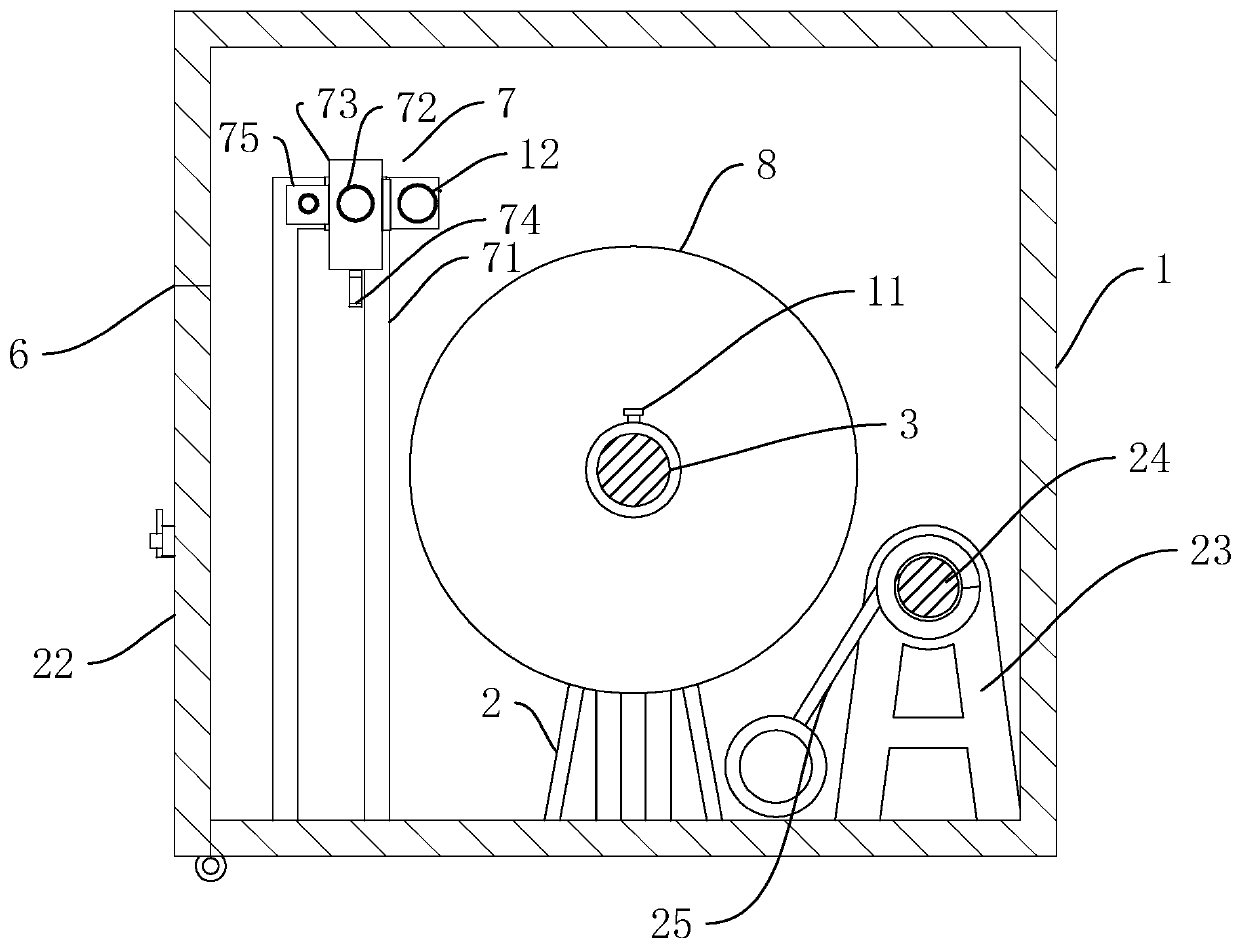

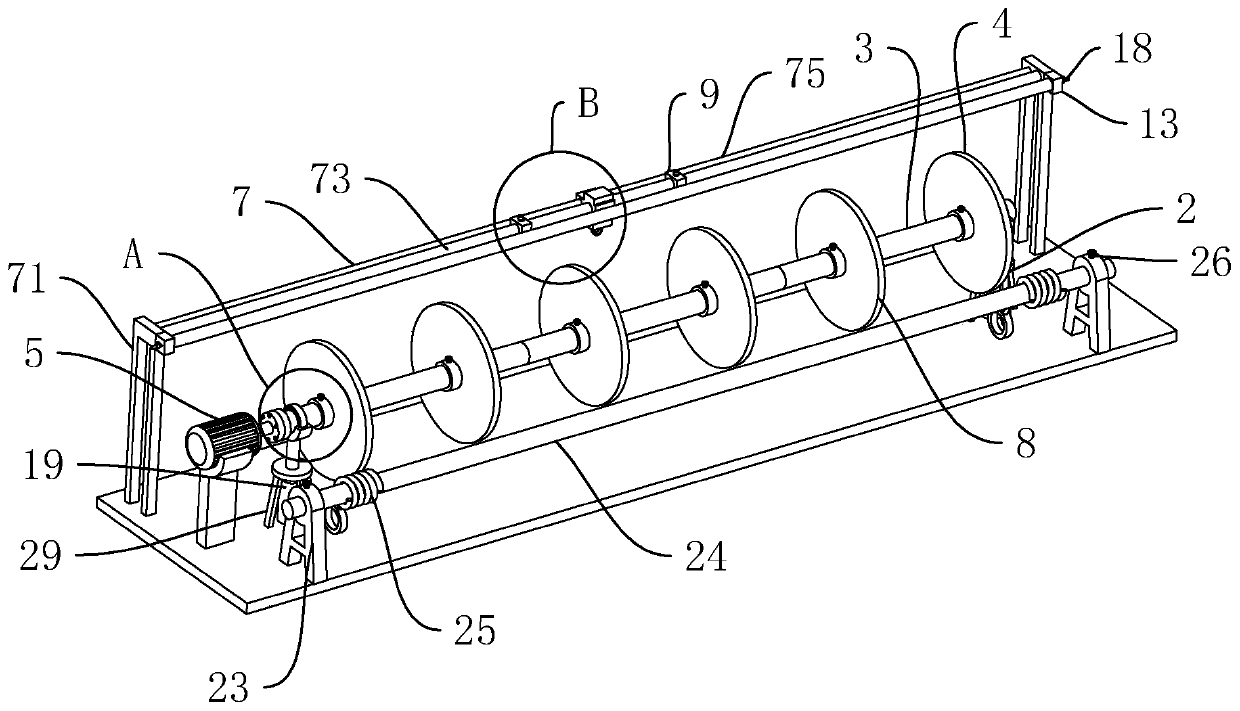

[0037] refer to figure 2 , image 3 and Figure 4, a support 2 is provided in the box body 1, and the support 2 includes a frame body 29 arranged on the left and right sides, each frame body 29 is provided with an oil cylinder 19, and a support seat 20 is provided on the output end of the oil cylinder 19, The oil cylinder 19 is connected with the oil pump, the support base 20 is U-shaped and the opening 6 is arranged upward, and the winding roller 3 is erected on the two support bases 20, and the two...

Embodiment 2

[0045] recombine as Figure 8 As shown, it is a transport vehicle disclosed by the present invention, including a vehicle body 30, on which the container in the first embodiment is installed, and when the cable needs to be wound up, the transport vehicle can be directly moved to the production workshop for The produced cables are reeled, so there is no need for hoisting, and the operation is more convenient and simple. At the same time, longer cables can be reeled at one time, reducing the joints between the cables in the later stage, thereby reducing the occurrence of later faults; when needed When the take-up roller 3 is rolled down from the box body 1, the hinged plate 22 can be opened to lean against the ground, and the two ends of the take-up roller 3 can be bound by two stay ropes 25, and then rolled The winding roller 3 makes it roll down along the hinge plate 22, and the winding roller 3 will be driven to rotate during the rolling down process of the winding roller 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com