Prefabricated wall body installing structure

A technology for installing structures and prefabricated walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of slow installation speed of scaffolding or scaffolding, reduced construction speed, and hidden safety hazards, so as to facilitate concrete pouring and improve Safety and stability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

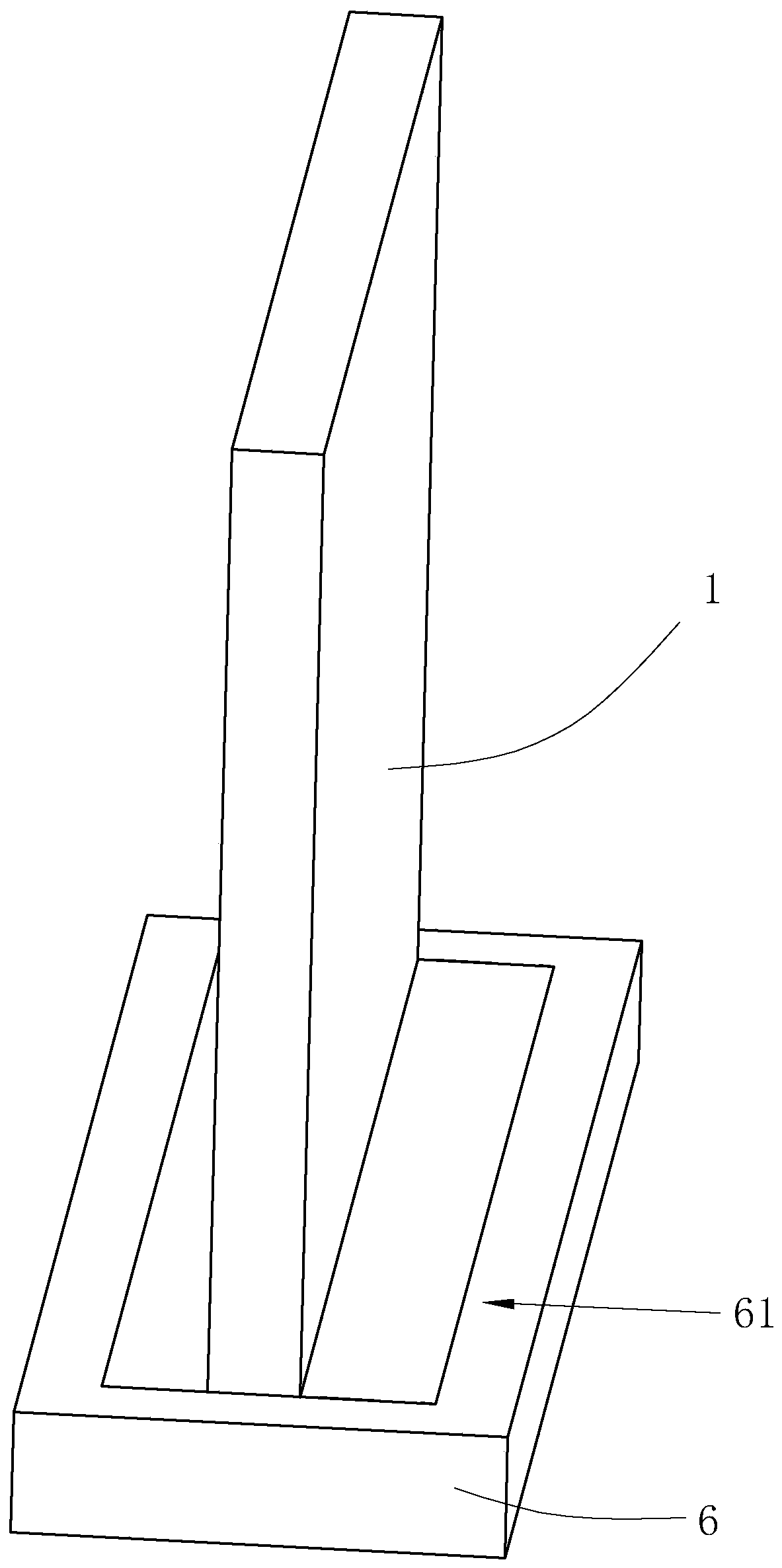

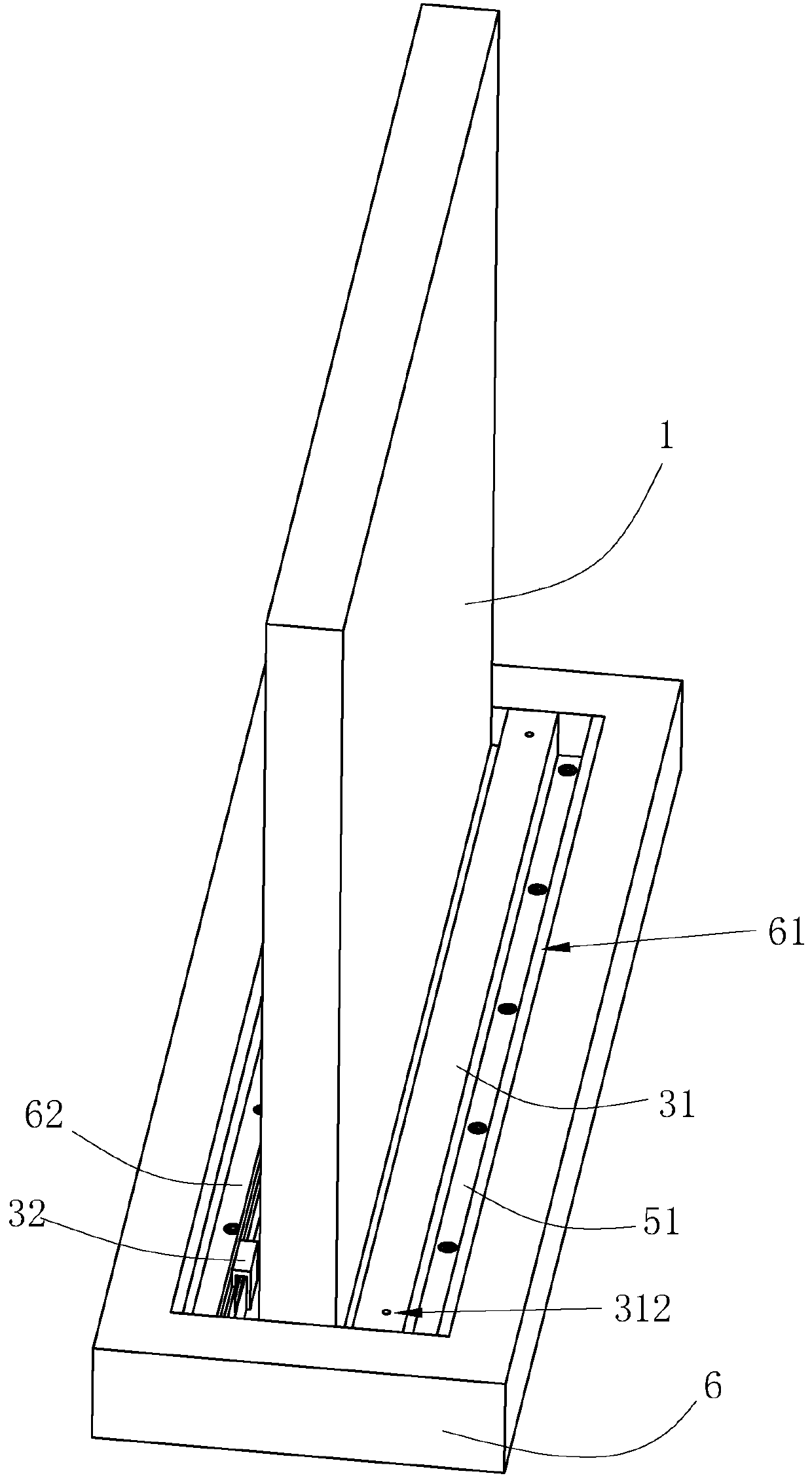

[0036] Such as Figure 1 to Figure 2 As shown, a prefabricated wall installation structure disclosed in the present invention is used to connect the prefabricated wall panel 1 with the floor 6, wherein the prefabricated wall installation structure is buried in the sinker 61 preset on the bottom plate 33, and the To quickly connect the prefabricated wall panel 1 and the floor 6 and support the positioning, and then realize the connection of the prefabricated wall panel 1 and the floor 6 by pouring concrete into the sinker 61 of the floor 6, thereby reducing the need for scaffolding and support racks The use of it improves the installation efficiency and reduces the production cost.

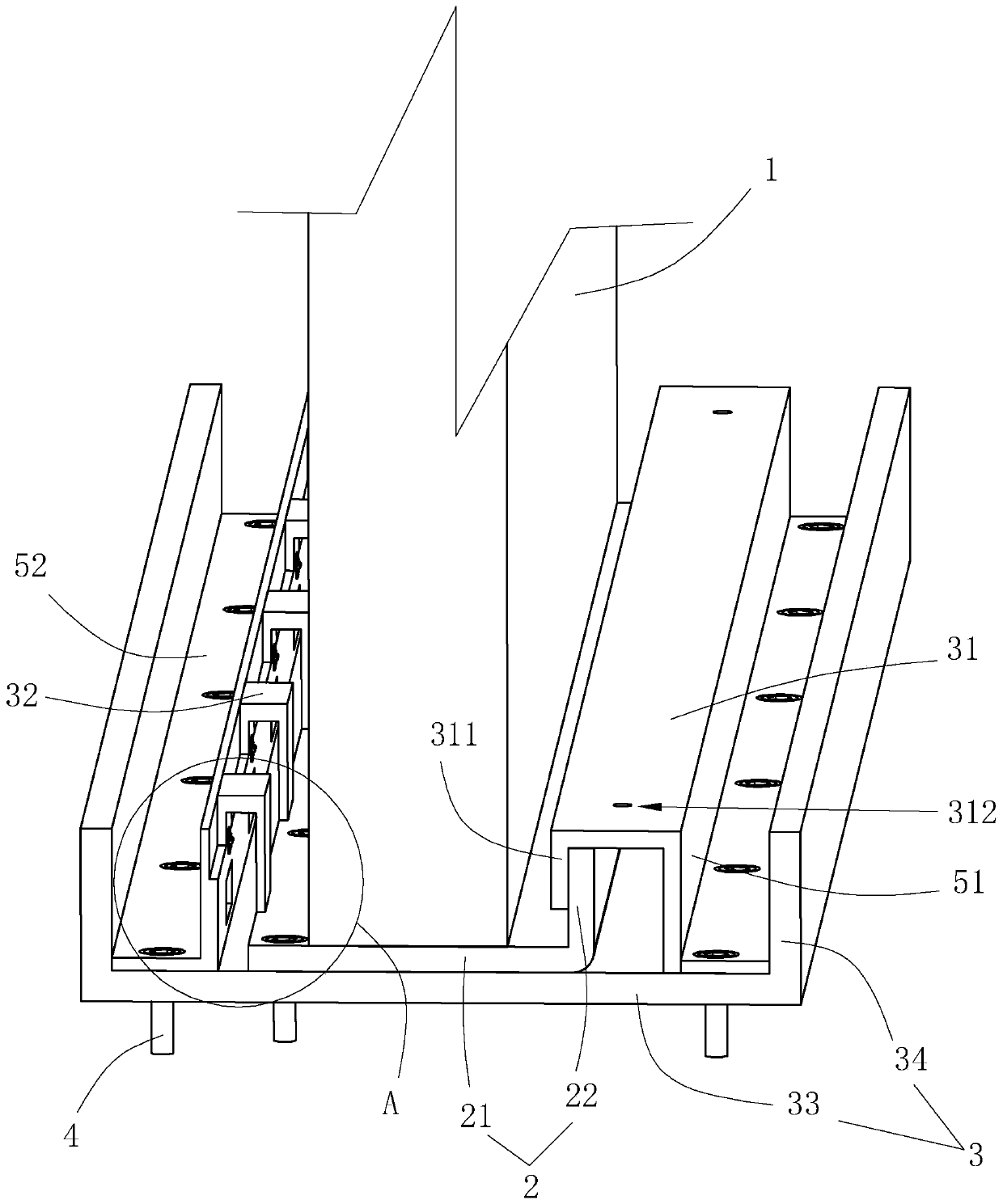

[0037] Such as Figure 2 to Figure 3As shown, the prefabricated wall installation structure includes an "L"-shaped connector 2 that is detachably fixed on the lower end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com