An automatic shaping device and shaping method for bonded magnet products

A technology of bonded magnets and products, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as low efficiency and precision, difficulty in shaping products, and high difficulty in shaping operations, so as to maintain ecological sustainability, The effect of high integer precision and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

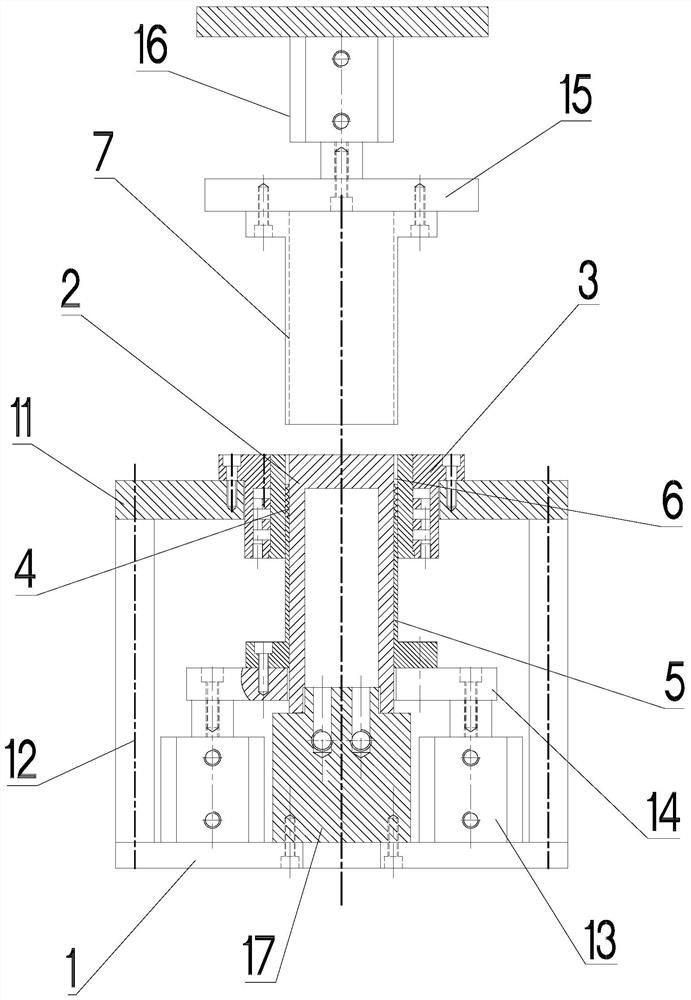

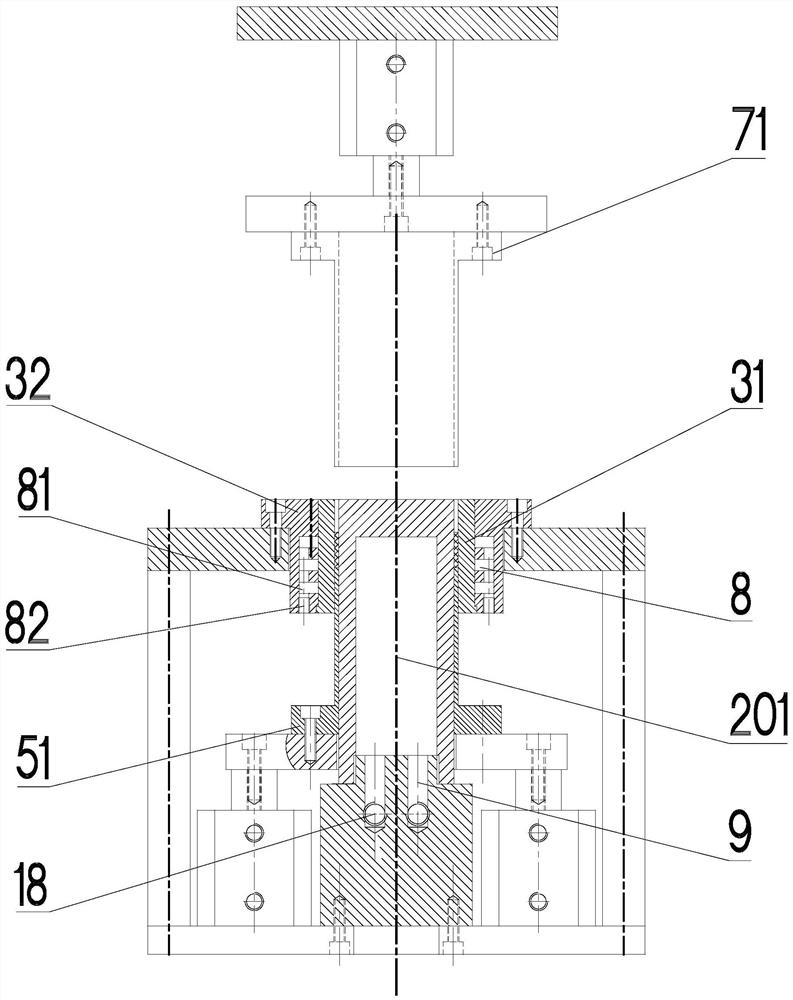

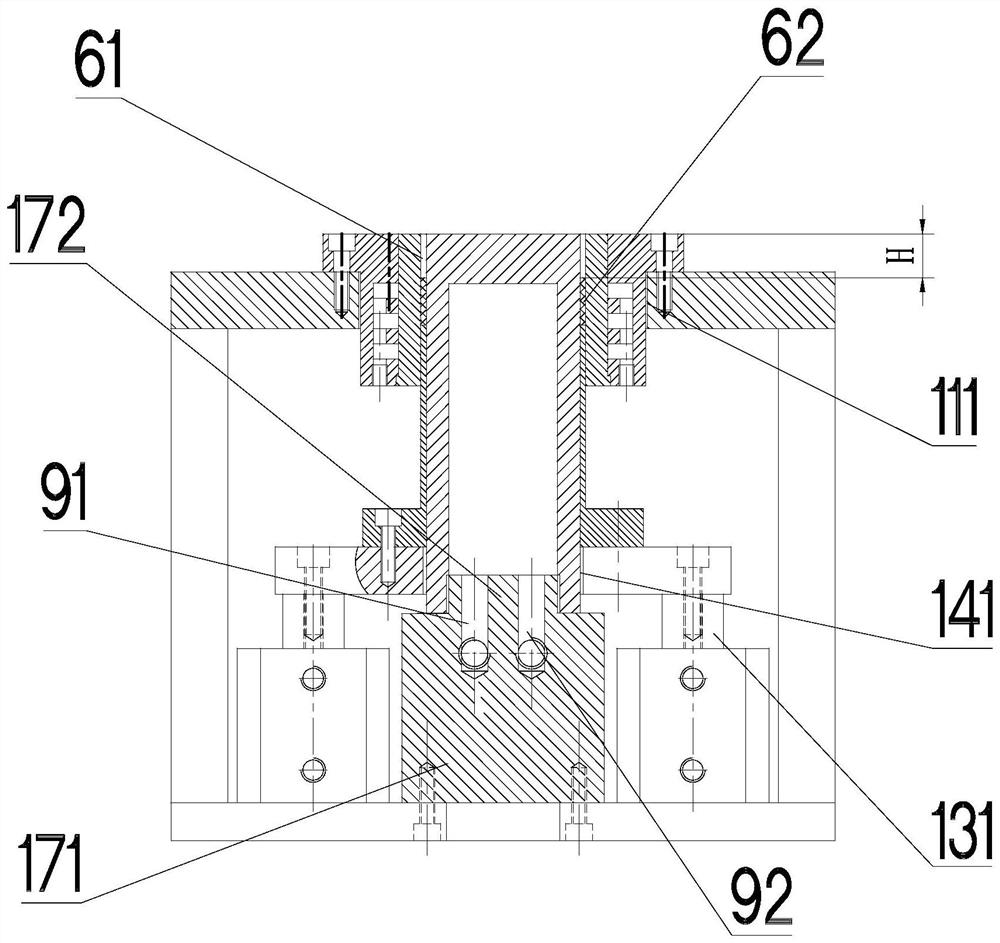

[0042] like Figure 1 to Figure 4 As shown, an automatic shaping device for bonded magnet products includes a bottom plate 1, a core 2 is fixedly connected to the bottom plate, and a die 3 is sleeved on the outer peripheral surface of the core with a radial gap between them. , the outer periphery of the core is provided with a lower punch 5 for carrying the product 4 to be shaped, and the bottom plate is provided with a driving member for driving the lower punch to slide back and forth along the length of the core, and the end of the lower punch away from the bottom plate is always Located inside the die, the upper end of the lower punch, the inner peripheral surface of the die and the outer peripheral surface of the core cooperate to form a plastic cavity 6 for plastic processing of the product to be shaped, and the upper punch located above the lower punch 7 Sliding axially along the ring-shaped shaping cavity, the die is provided with a first cooling channel 8 for cooling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com