Mullite-corundum composite ceramic as well as preparation method and application thereof

A composite ceramic and mullite technology, which can be used in other household appliances, ceramic material production and application, etc., can solve the problems of failure to achieve high-value utilization, complex processes, and differences in ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

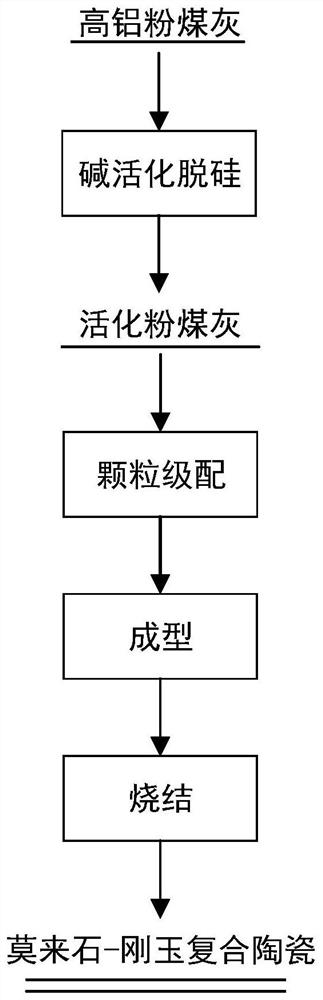

[0076] The fly ash used in this example is the fly ash of a thermal power plant in the Inner Mongolia Autonomous Region, wherein the content of alumina is 46wt%, and the content of silicon dioxide is 39wt%. The production of mullite-corundum composite ceramics in this example is based on figure 1 process flow.

[0077] (1) fly ash is mixed with the NaOH alkali solution of 2.5mol / L with concentration, the ratio of the volume of described NaOH alkali solution and the quality of fly ash is 10L / g, and the closed reactor carries out activation reaction, and reaction temperature is 95°C, the reaction time is 3 hours, fully stirred, after the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash as a ceramic raw material;

[0078] (2) After sieving the activated fly ash, the activated fly ash with D1<20μm accounts for 50% of the total mass, the activated fly ash with 20μm≤D2<30μm accounts for 40% of the total mass, and the activated fly ash with...

Embodiment 2

[0082] This example adopts the fly ash of a thermal power plant in Shanxi Province, wherein the content of alumina is 52wt%, and the content of silicon dioxide is 42wt%. The production of mullite-corundum composite ceramics in this embodiment is based on figure 1 process flow.

[0083] (1) The fly ash raw material is added in the high-temperature, high-pressure homogeneous reactor, and the fly ash is mixed with the NaOH alkali solution of 5mol / L with a concentration, and the ratio of the volume of the NaOH alkali solution to the mass of the fly ash is 5L / g, closed reactor for activation reaction, the reaction temperature is 150°C, the reaction time is 0.5h, fully stirred, after the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash as a ceramic raw material;

[0084] (2) After the activated fly ash is sieved, the activated fly ash of D1<20 μm accounts for 80% of the total mass, and the activated fly ash of 30 μm≤D3≤50 μm accounts for 2...

Embodiment 3

[0087] This example adopts the fly ash of a thermal power plant in Tianjin, wherein the content of alumina is 42wt%, and the content of silicon dioxide is 36wt%. The production of mullite-corundum composite ceramics in this embodiment is based on figure 1 process flow.

[0088] (1) The fly ash raw material is added in the high temperature and high pressure homogeneous reactor, and the fly ash is mixed with the NaOH alkali solution of 1mol / L with a concentration, and the ratio of the volume of the NaOH alkali solution to the mass of the fly ash is 10L / g, closed reactor for activation reaction, the reaction temperature is 150 °C, the reaction time is 5h, fully stirred, after the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash as a ceramic raw material;

[0089] (2) After sieving the activated fly ash, the activated fly ash with D150μm Fly ash accounts for 10% of the total mass. Mix it, then add water and mix evenly to obtain a materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com