Ceramic photoelectric coupler and manufacturing method thereof

A technology of optocoupler and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of complex production process, cumbersome packaging process, complex structure, etc., achieve mechanical shock resistance and reduce process assembly Difficulty, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

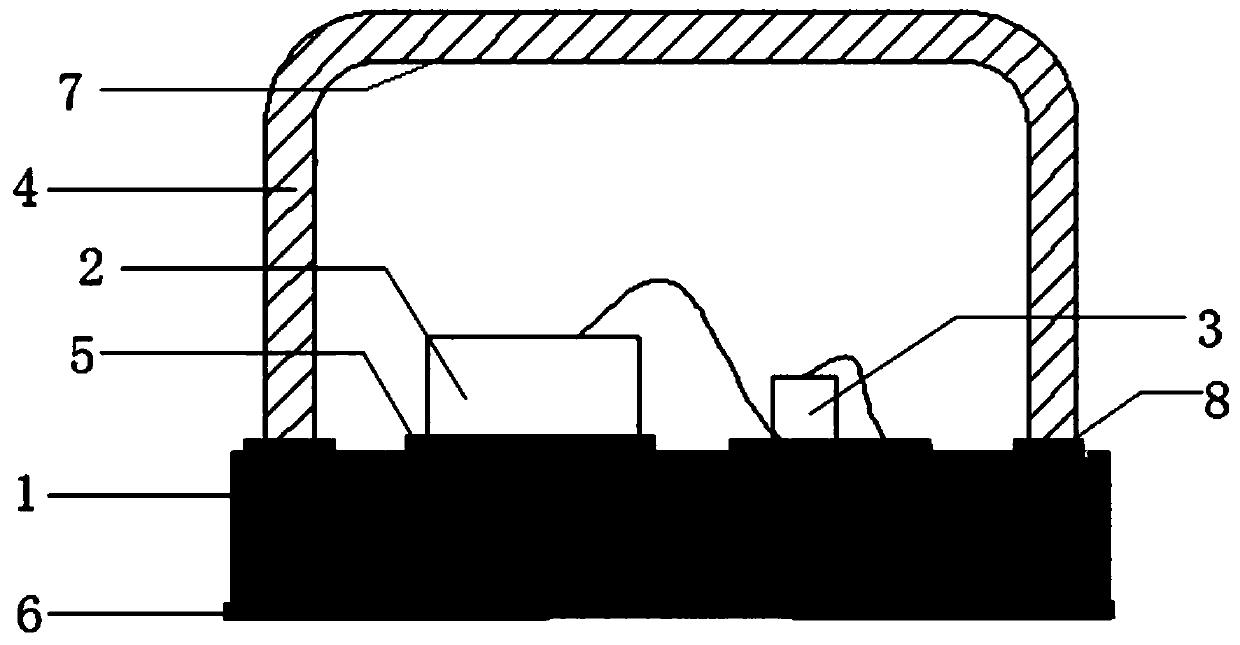

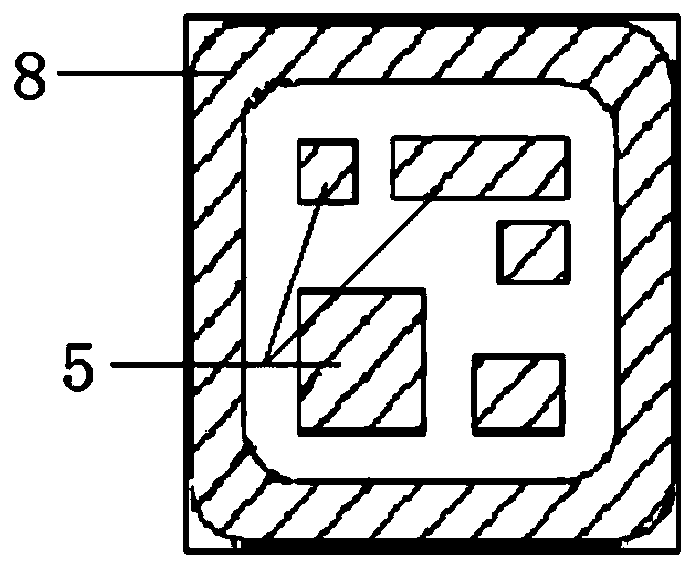

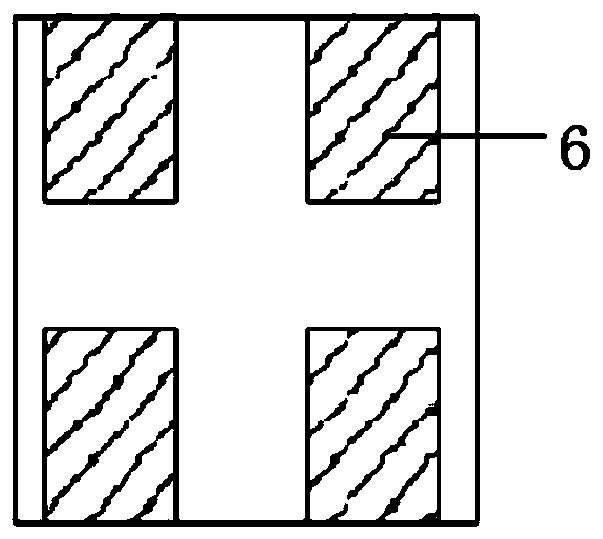

[0025] like Figure 1-3 As shown, the ceramic optocoupler of the present embodiment includes a multilayer ceramic substrate 1 and a metal cap 4 which is arranged on the ceramic substrate 1 and forms a sealed cavity with the upper surface of the ceramic substrate 1. There is a metallization area 8 for welding the metal cap 4 and a metallization area 5 for connecting components. The metallization area 8 and the metal cap 4 are connected by gold-tin welding to realize integrated sealing. A light-emitting diode 3 and a phototransistor 2 are installed on the multilayer ceramic substrate 1, and different electrodes of the light-emitting diode 3 and the phototransistor 2 are respectively electrically connected to the specific metallization area 5 on the upper surface of the multilayer ceramic substrate 1; the multilayer ceramic substrate The metallization 5 on the upper surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com