Semi-automatic disassembling and classifying wire for waste conditioner

A semi-automatic and obsolete technology, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the problems of low degree of automation, low transmission efficiency, and single function, so as to save manpower, high transmission efficiency, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

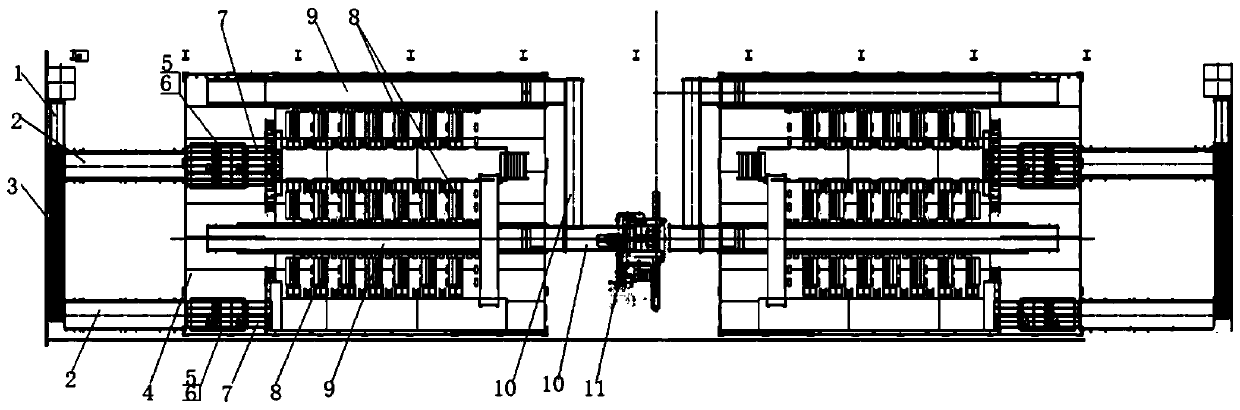

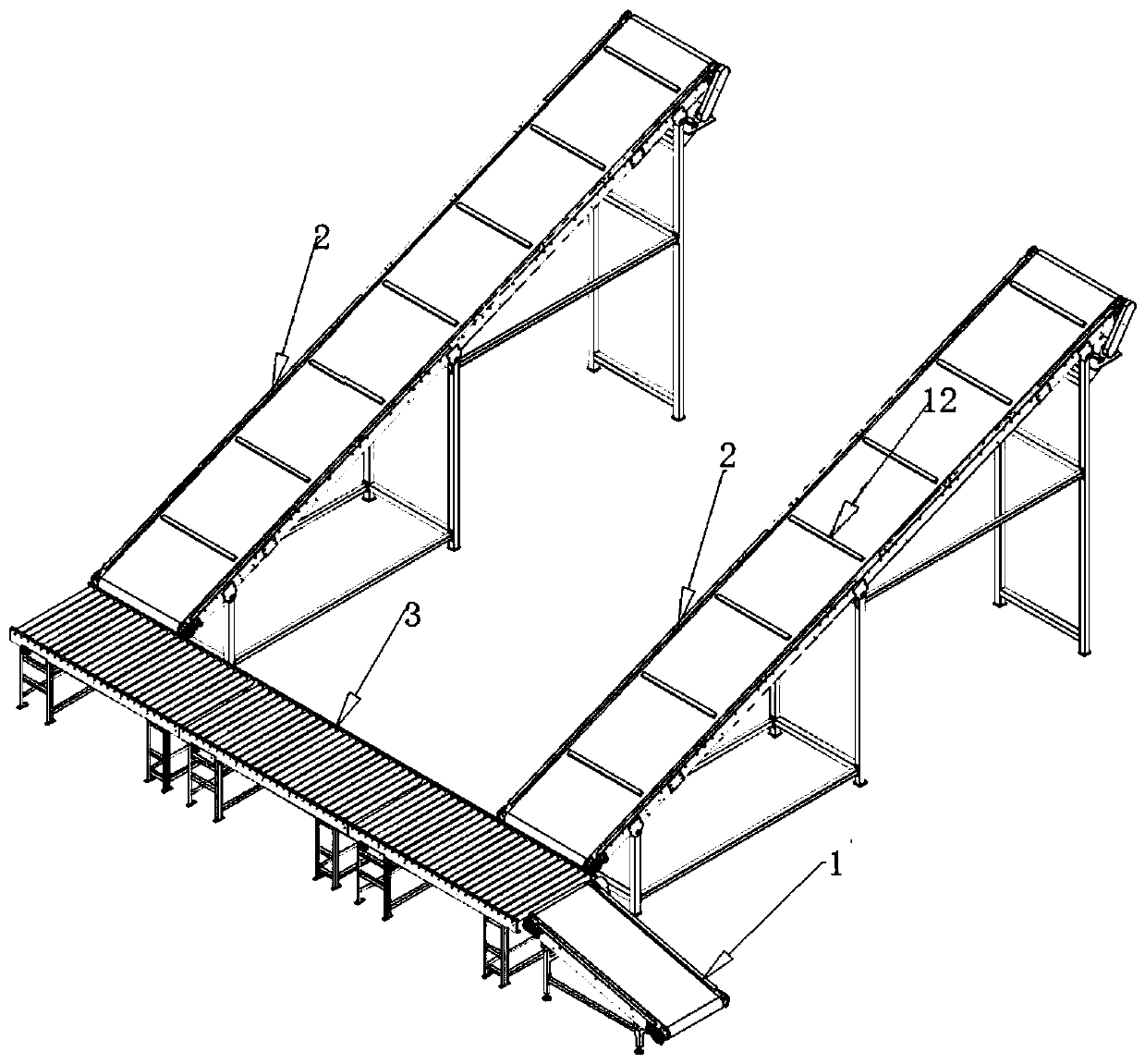

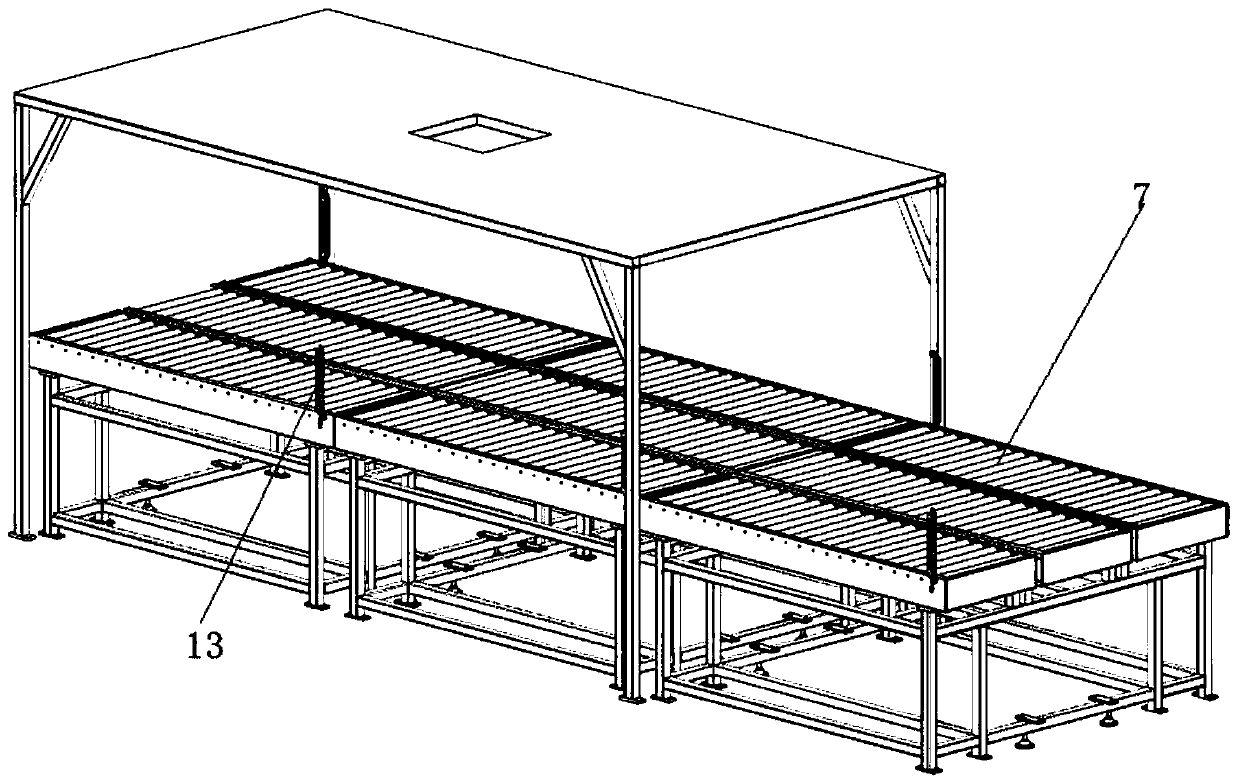

[0024] Such as figure 1 with Figure 5 As shown, a semi-automatic dismantling and sorting line for waste air conditioners includes a lifting conveyor 2 (belt conveyor is used), a packaging and shaping device 11 capable of compressing the compressor and packing, and an elevated dismantling platform 4, on which there is a There is a dismantling conveyor 7 (using a roller conveyor), a sorting and screening conveyor 9 (using a belt conveyor) and an integrated dismantling console 8 for dismantling waste air-conditioning equipment, and the lower end of the lifting conveyor 2 is connected to the feeding point and the upper end Connected with the dismantling conveyor 7, the dismantling platform 4 is provided with a refrigerant extraction device 5 and a compressor drilling oil discharge device 6 near the front end of the dismantling conveyor 7, and the dismantl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap