A method for internal pressure forming of large-scale thin-walled pipe fittings with gas-liquid mixed fluid

A gas-liquid mixing, large-scale technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of pressure rise, high equipment cost, low efficiency, etc., and meet the requirements of improving stability and reducing sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a gas-liquid mixed fluid internal pressure forming method for large-scale thin-walled pipe fittings, which includes the following steps:

[0039] Step 1. Determine the internal pressure; analyze the characteristics of the part to be formed, and determine the value of the support internal pressure required for forming;

[0040] Step 2, calculate the volume; calculate the inner cavity volume of the original tube blank 11 and its change in the whole forming process;

[0041] Step 3, determine the gas-liquid volume ratio; according to the change characteristics of the inner cavity volume of the tube blank 11, determine the sequence and volume ratio of filling the gas medium and liquid medium into the tube blank 11;

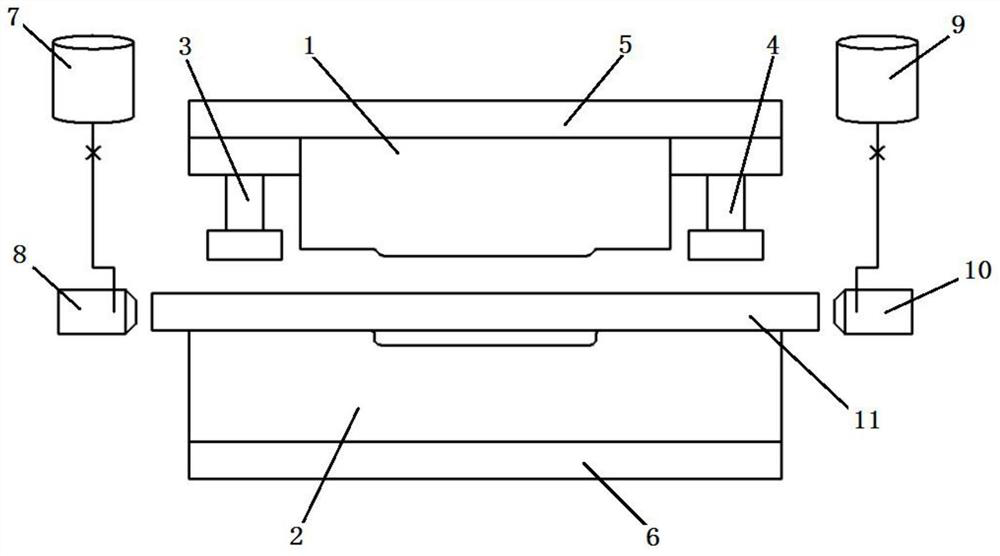

[0042] Step 4, placing the tube blank 11; figure 1 As shown, the large-size thin-walled tube blank 11 to be formed is placed on the mold, and the mold is closed to a certain position;

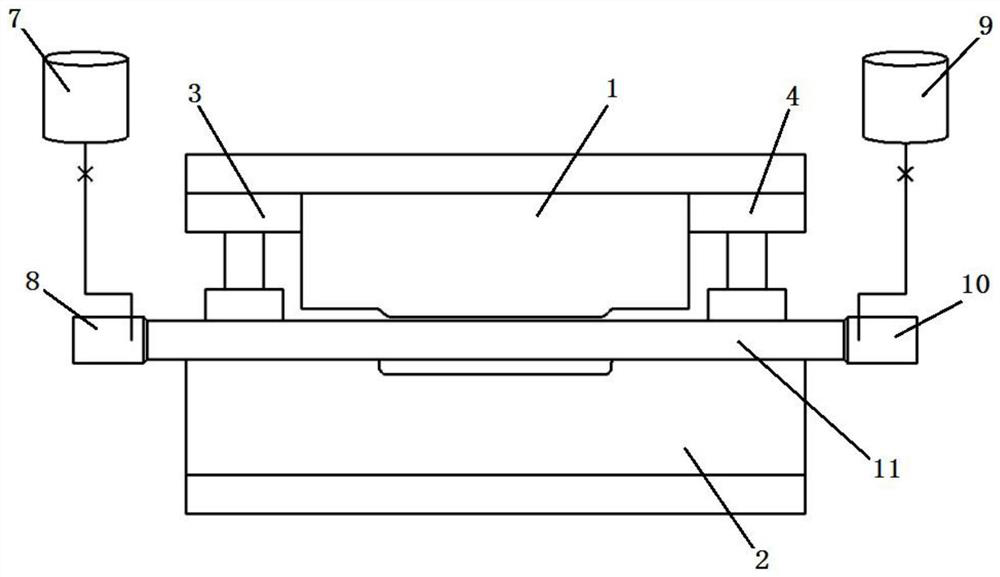

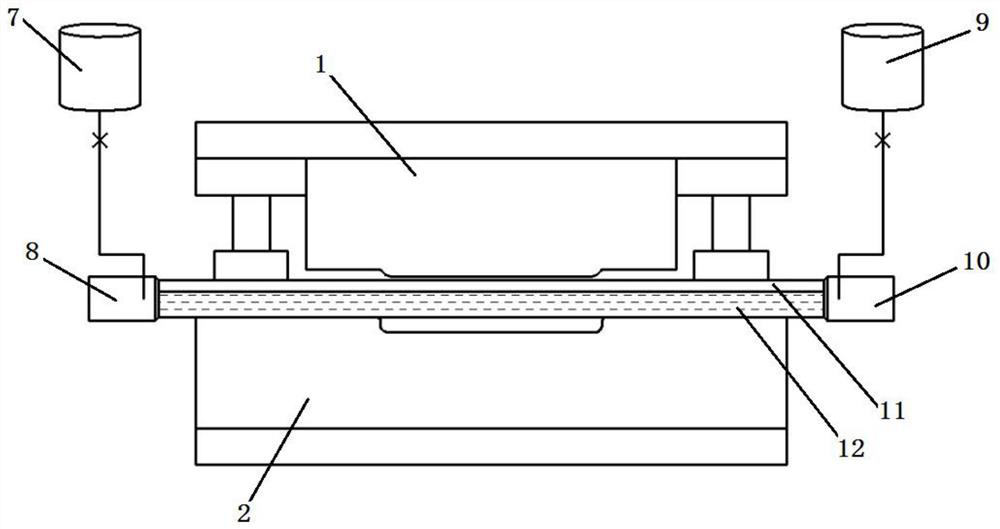

[0043] Step five, end sealing; figure 2 As sho...

Embodiment 2

[0052] In the gas-liquid mixed fluid internal pressure forming method for large-scale thin-walled pipe fittings provided in this example, in step 2, only the inner cavity volume of the original tube blank and the inner cavity volume of the final part are calculated, and the volume change during the entire forming process is not calculated . Other steps are the same as in Embodiment 1.

[0053] The beneficial effects of this embodiment are: for large-sized tube blanks, there is no need to calculate the volume change in the whole process, and there is no need to adjust the pressure in real time; During the forming process, the change in the volume of the inner cavity of the tube blank is only 10-20% of the volume of the original tube blank. Due to the large compression ratio of the gas, the relative change of the gas pressure in the inner cavity of the tube blank is only 10-25%. This variation range of the gas pressure will not have an adverse effect on the forming process, so...

Embodiment 3

[0055] In the gas-liquid mixed fluid internal pressure forming method for large-scale thin-walled pipe fittings provided in this embodiment, in step 6, the volume of liquid charged into the tube blank is about 50-100 liters. Other steps are the same as in Embodiment 1.

[0056] The beneficial effects of this embodiment are: large-size tube blanks occupy space by using liquid, use gas to provide pressure, high efficiency and low cost; pre-fill a large volume of liquid into the cavity of large-size thin-walled tube blanks, and then fill the tube The remaining space in the inner cavity of the billet is filled with gas, that is, the liquid is used to occupy most of the space first, and then the gas is used to provide the support pressure, which solves the problem of "inflating and pressing" that only uses gas for internal support. The problem of long inflation and deflation time and low production efficiency caused by high air pressure. At the same time, the preparation and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com