Mechanism capable of improving overall box feeding

An overall, carton technology, applied in the field of automated production equipment, can solve the problems of low automation and low production efficiency, and achieve the effects of high automation, improved production efficiency, and overall compact production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

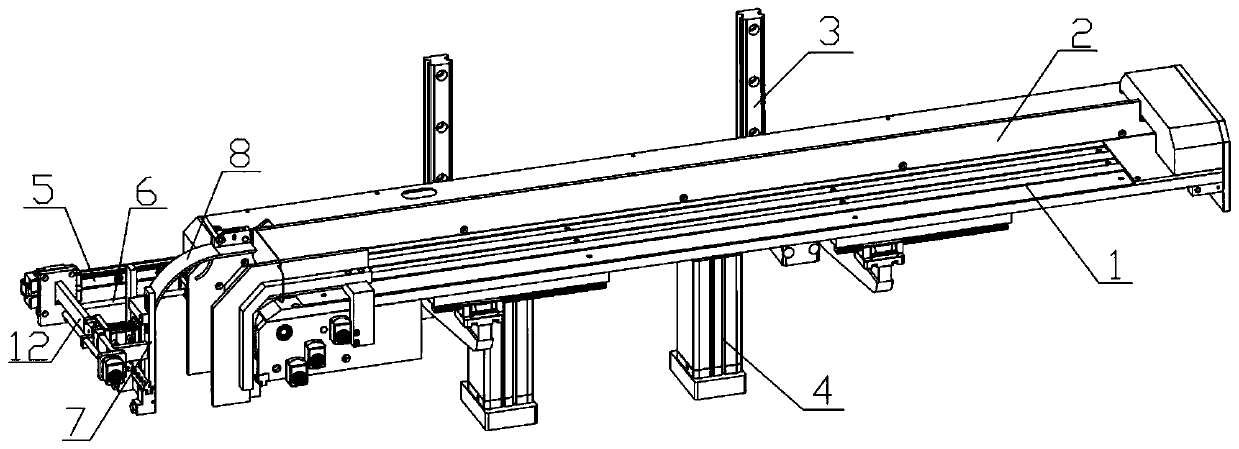

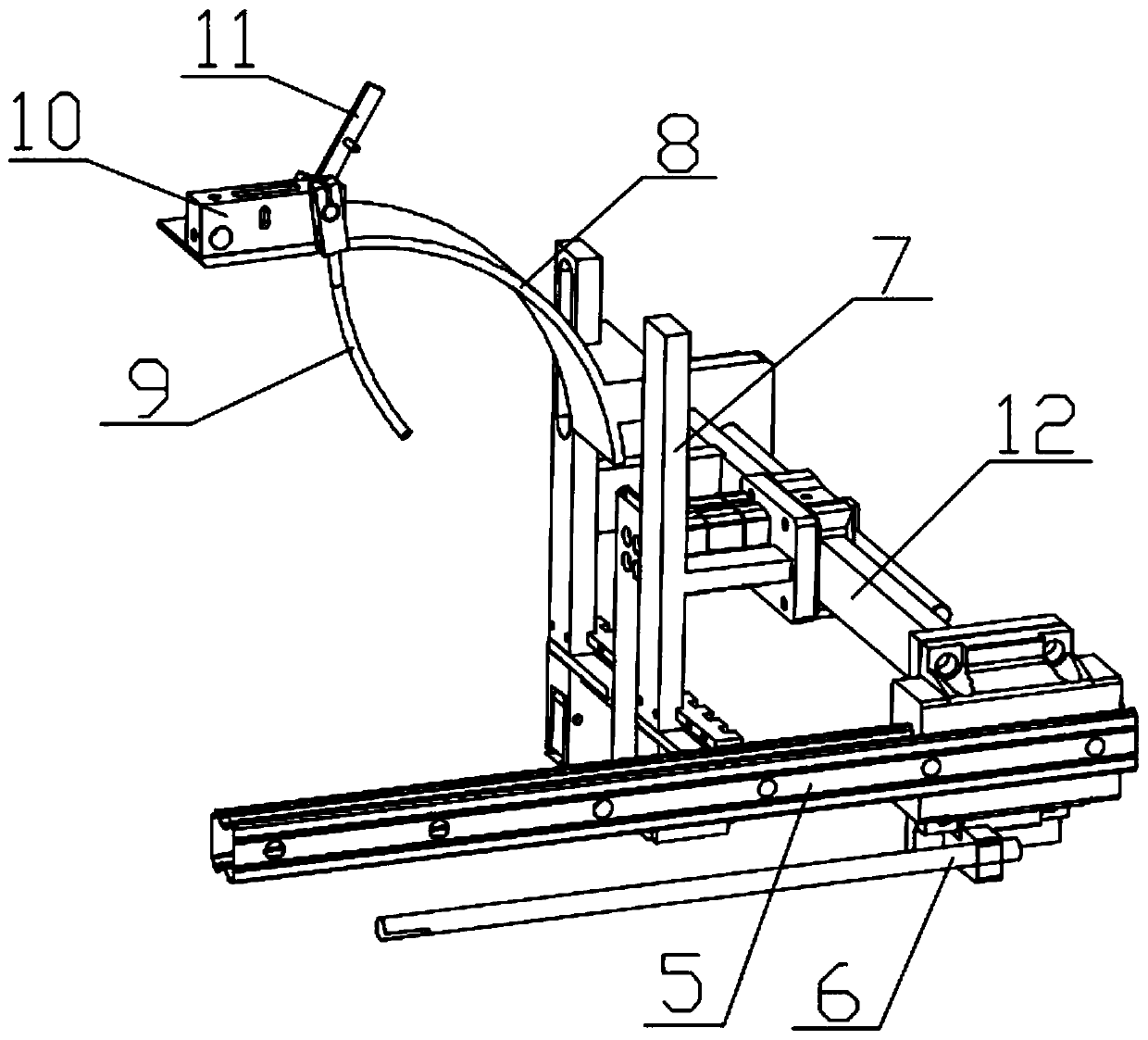

[0020] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 And attached figure 2 The liftable integral lower box mechanism provided by the present invention is described in detail.

[0021] In this embodiment, it mainly includes the conveying track 1 , the lower box slider 7 and other accessories arranged on the lower box slider 7 .

[0022] The upper end surface of the conveyor track 1 is provided with several conveyor belts along the length direction of the conveyor track 1. Generally, there are three conveyor belts, and the conveyor belts are arranged in parallel. Several cartons can be placed on the upper side of the conveyor belt. Through the movement of the conveyor belt To convey the cartons, the conveying track 1 can slide along the height direction of the vertical guide rail 3 and be connected with the vertical guide rail 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com