Mutton, beef, pork and chicken rolling machine

A technology for rolling machine and chicken, which is applied in the field of rolling machine for sheep, cattle, pigs and chicken, can solve the problems that meat products are not easy to be filled, difficult to pack into columnar products, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, invention is described in further detail:

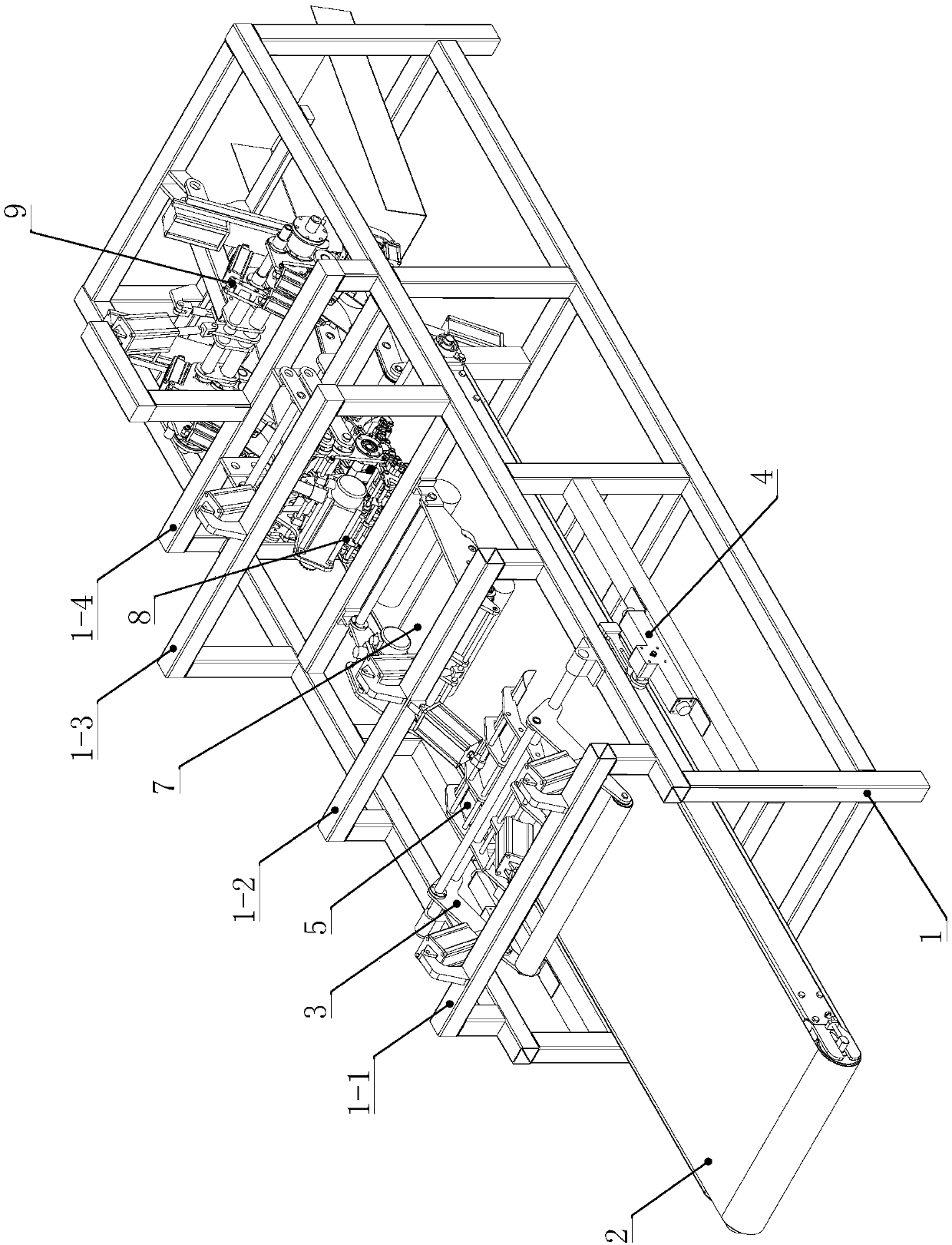

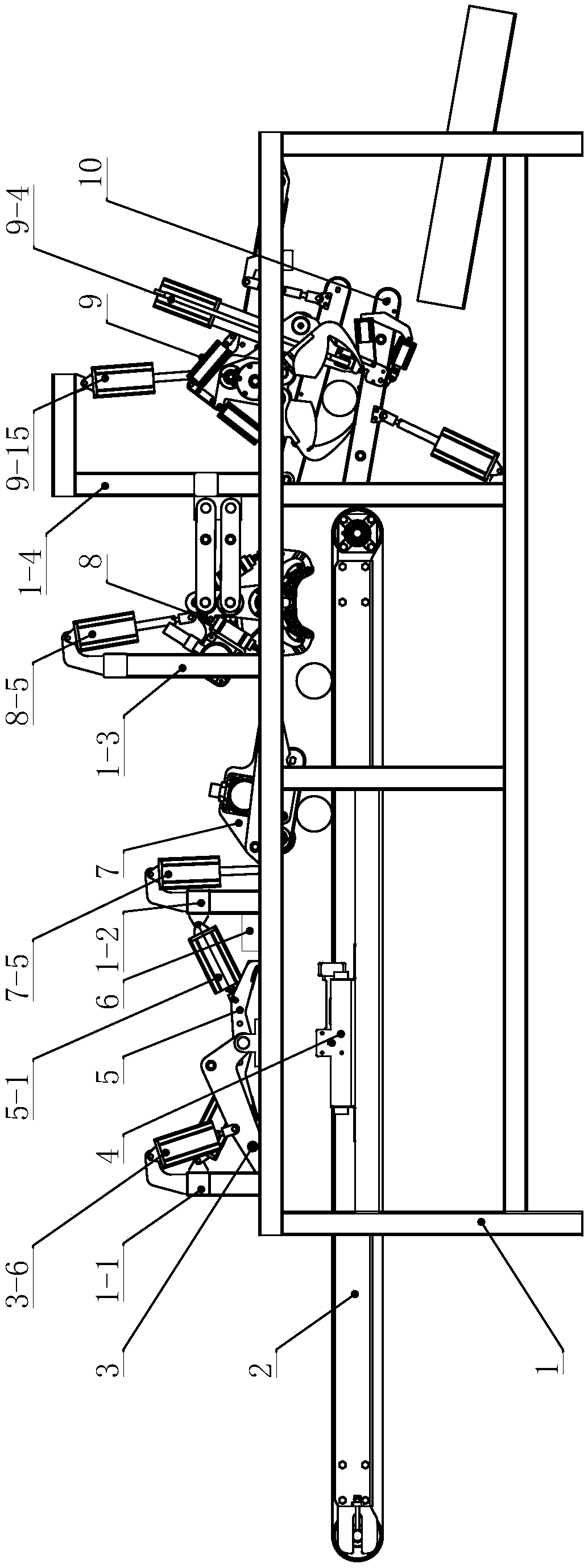

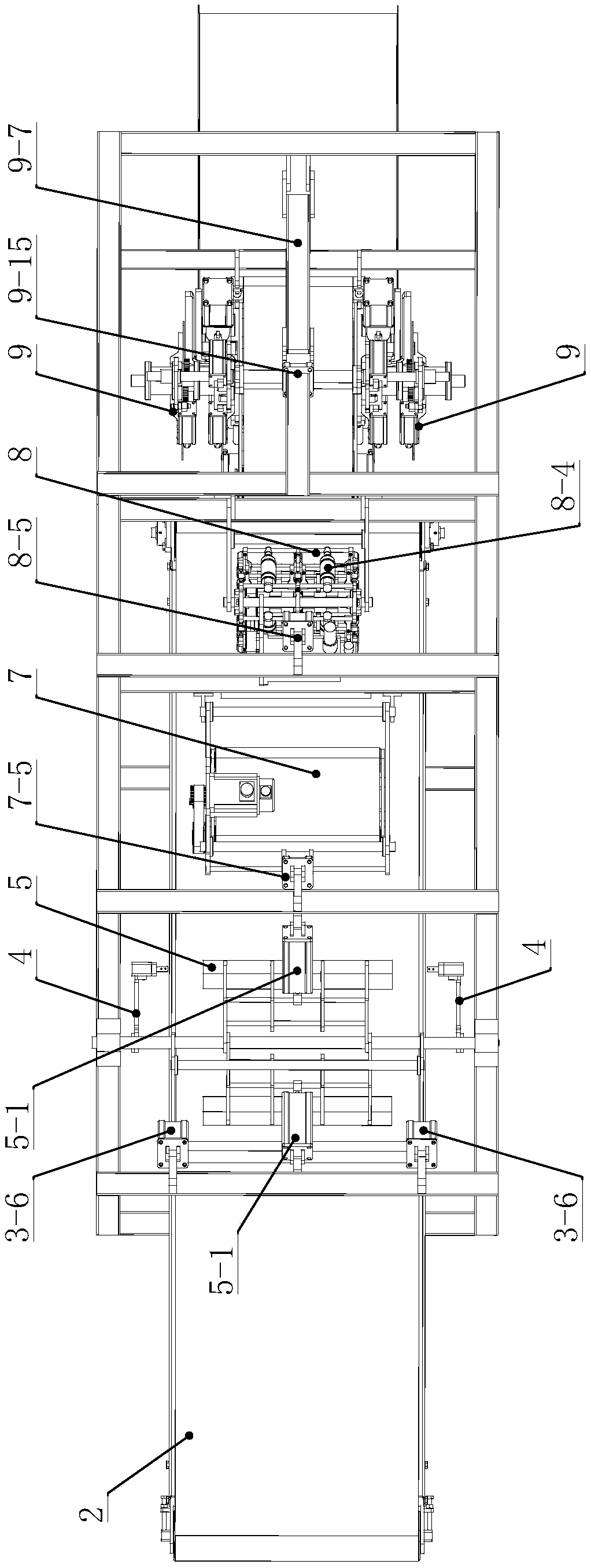

[0027] like figure 1 and Figure 2A , Figure 2BAs shown, the present invention includes a frame 1 and a conveying assembly 2 fixed on the frame, a film pressing assembly 3, a film turning assembly 4, a mask assembly 5, a rolling assembly 7, a rolling assembly 8, and a U-shaped aluminum buckle The sealing and shearing assembly 9 and the dragging and discharging assembly 10 of sealing, wherein the conveying assembly is an endless conveying assembly, including a food-grade PVC endless conveyor belt, a driving shaft, a driven shaft, a motor, etc., and the conveyor belt is tensioned between the driving shaft and the driven shaft. On the shaft, the motor drives the driving shaft to rotate, and then drives the conveyor belt to rotate, so as to drive the products to be packaged on the conveyor belt forward. The lamination assembly, mask assembly, roll assembly and roll assembly are f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap