Hub hoisting device of electric vehicle

The technology of a hoisting device and an electric vehicle is applied in the field of electric vehicles, which can solve the problems of difficult operation and inconvenient handling, and achieve the effect of convenient hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

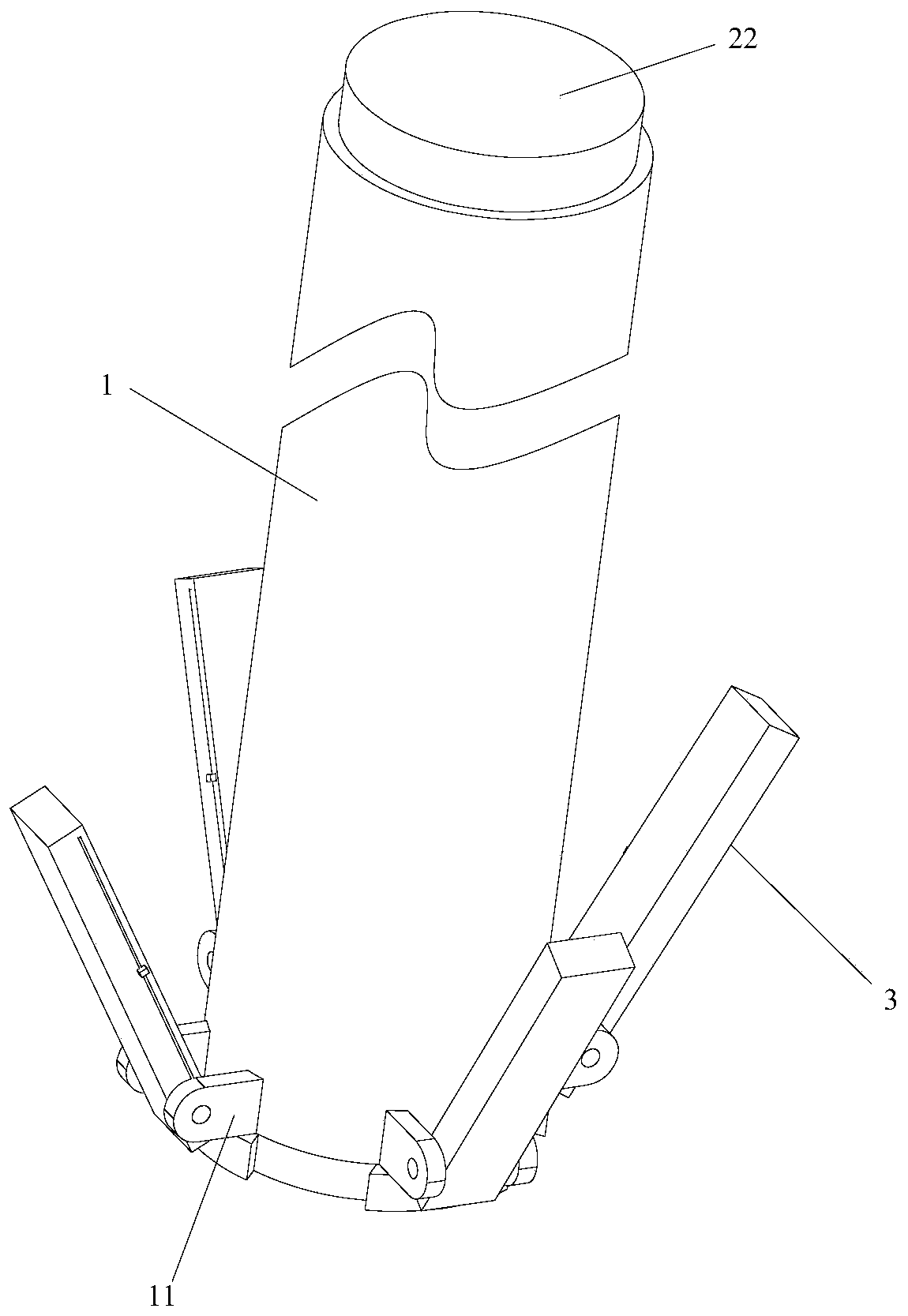

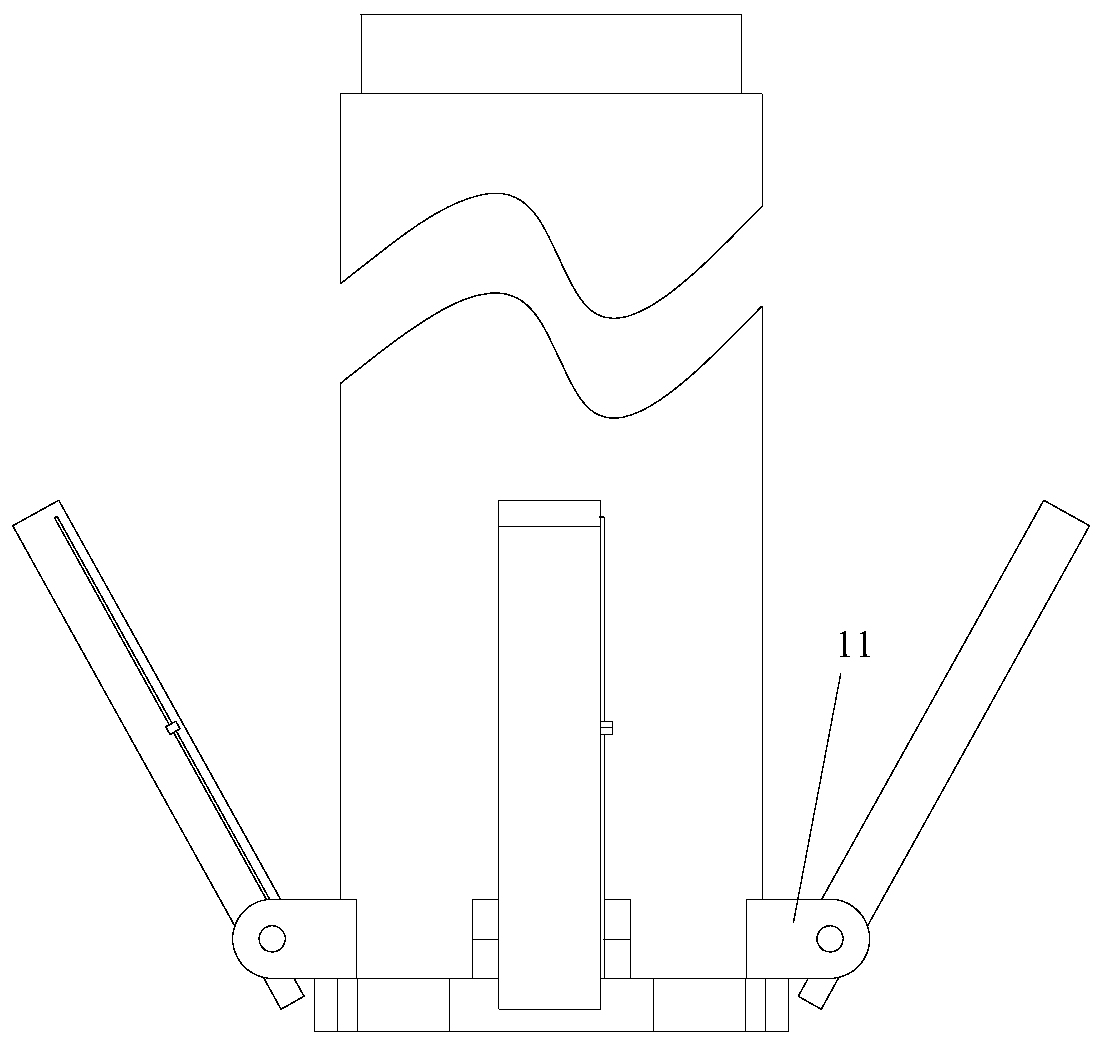

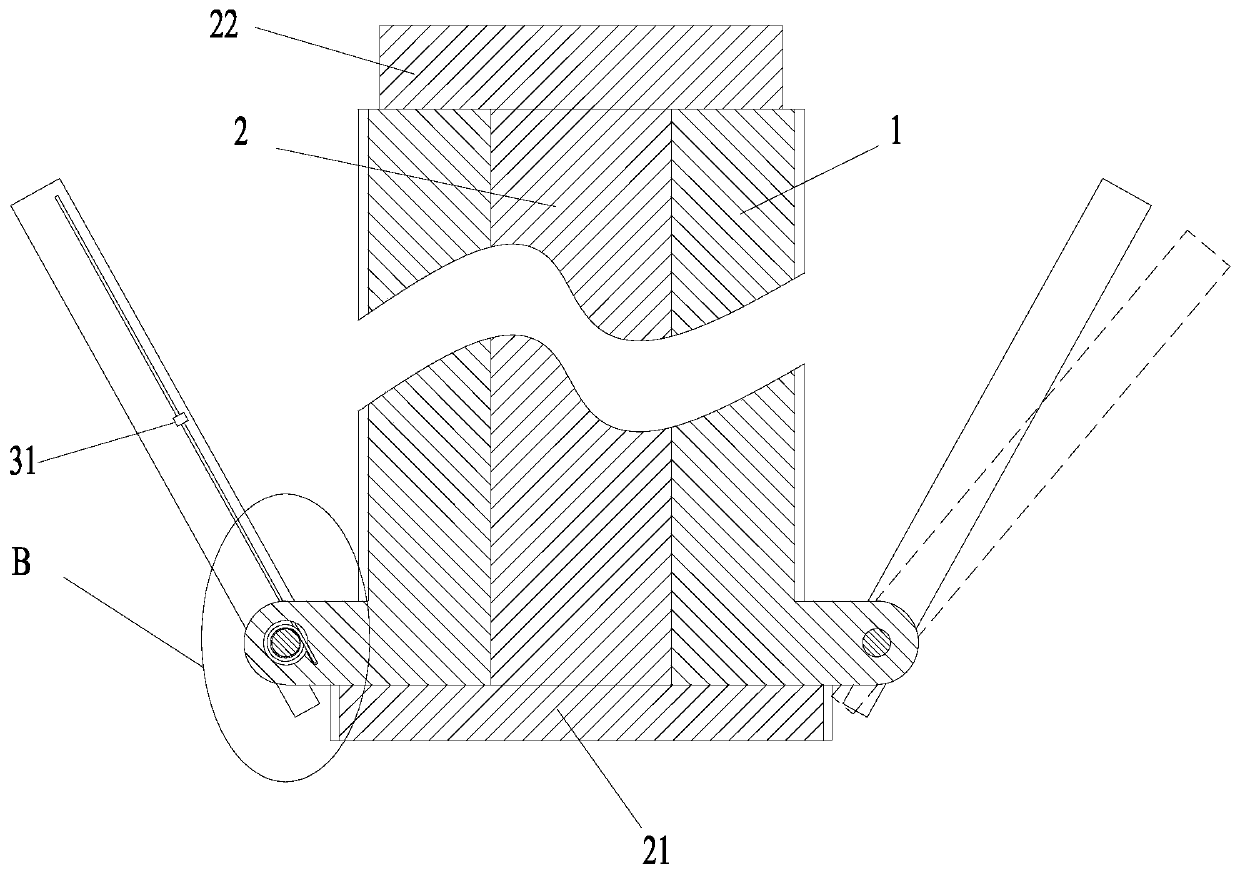

[0023] Such as Figure 1 to Figure 8 As shown, the present invention provides a hoisting device for an electric wheel hub, which includes a mounting cylinder 1 and an adjusting shaft 2 rotatably arranged in the mounting cylinder 1. One end of the mounting cylinder 1 is provided with several To the evenly distributed hinge seat 11, the hinge seat 11 is provided with a rotatable card column 3, and the end of the adjustment shaft 2 near the hinge seat 11 is fixed with a limit plate 21 coaxial with it; The post 3 hovers on the hinge seat 11 through the elastic part.

[0024] Further, the limit plate 21 is provided with several notches 211 corresponding to the clamping posts 3 one by one. The setting of these notches 211 makes the limit plate 21 form several 3 corresponds to the flange 212 one by one, and the end of the post 3 close to the hinge seat 11 is provided with a rectangular slot 33; when the notch 211 corresponds to the post 3, the post 3 is close to the post 3 One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com