Overturning technology for ultra-large rail-mounted gantry crane girder structure in workshop

A track crane, super-large technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unable to meet the needs of super-large rail crane girder turning over, to reduce the generation of prestress, reduce process time, and twist controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

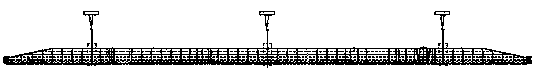

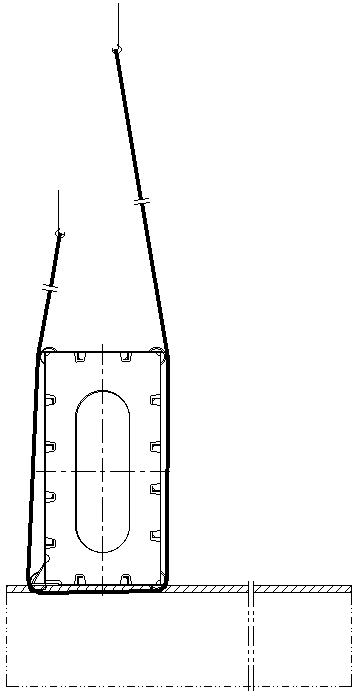

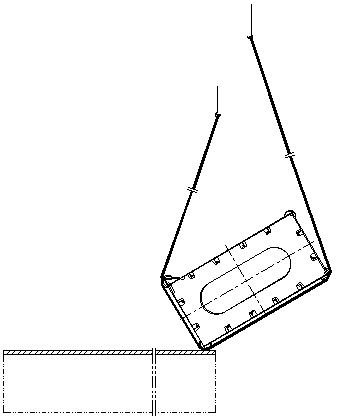

[0018] Such as Figure 1 to Figure 6 The specific process steps are as follows: S1: assembly and welding of auxiliary tooling; S2: insertion of steel wire rope; S3: crane lifting and turning over; S4: main girder inspection.

[0019] S1: Assembly and welding of auxiliary tooling: at the four end corners at the central position of the main beam, and at the four end corners at the two ends 35.5m away from the center of the main beam; where the main The ribbed plate is welded between the end corner of the beam body and the side of the main beam, and the ribbed plate forms a triangular structure with the rail bearing beam and the side of the main beam; Protective plate; the corner protective plate has an arc-shaped structure, wrapped on the end corner of the main girder and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com