Oil discharging system exhauster and oil discharging system

A technology of oil unloading system and exhaust device, which is applied in the field of oil transportation, can solve problems such as being discharged indoors, and achieve the effect of eliminating potential safety hazards and avoiding air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

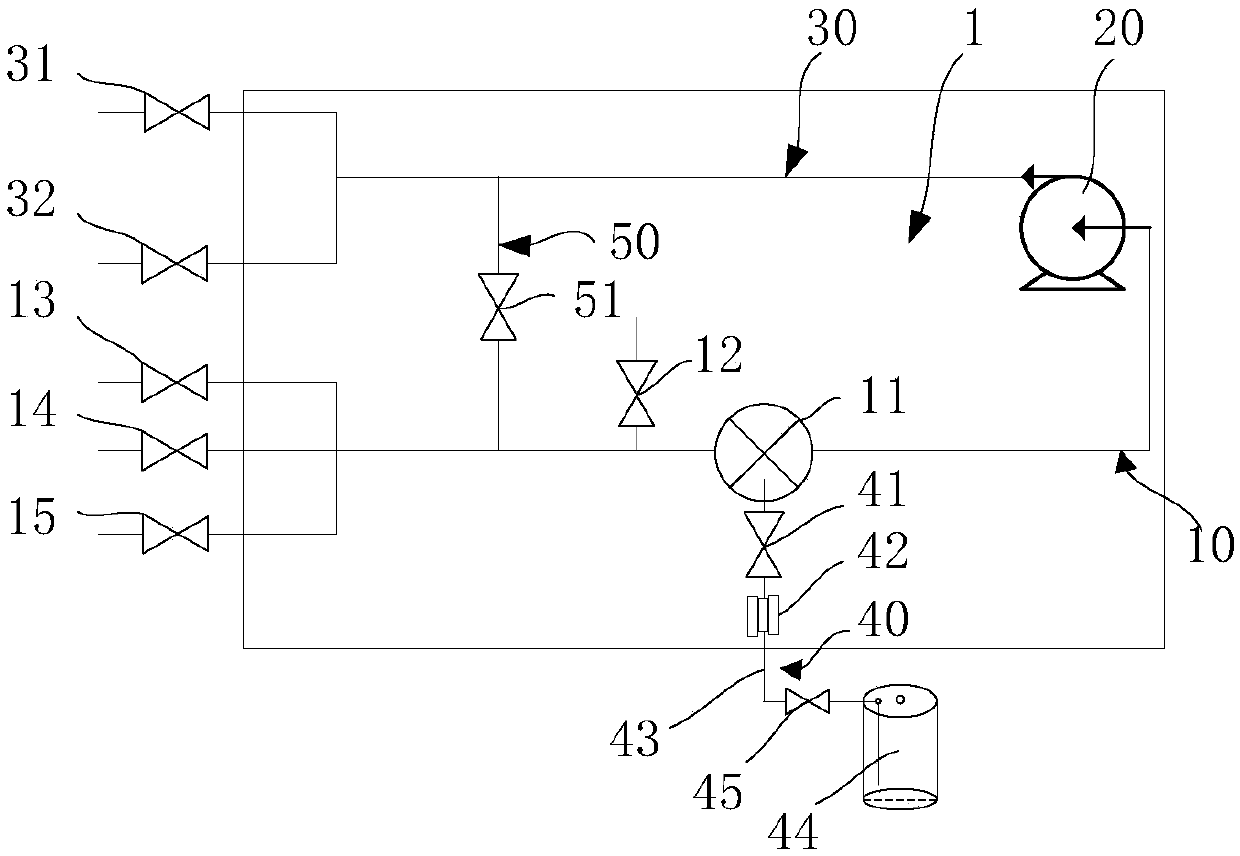

[0022] figure 1 It is a schematic diagram of an oil unloading system provided by an embodiment of the present invention. Such as figure 1 As shown, the oil unloading system includes an oil unloading circuit 1 . The oil unloading circuit 1 includes an oil inlet pipeline 10 , an oil pump 20 and an oil outlet pipeline 30 . The oil inlet pipeline 10, the oil pump 20 and the oil outlet pipeline 30 are connected in sequence.

[0023] Optionally, at least one stop valve is installed on the oil inlet pipeline 10 . For example, in figure 1 In the illustrated embodiment, there are three, namely the first cut-off valve 13 , the second cut-off valve 14 and the third cut-off valve 15 . The first shut-off valve 13, the second shut-off valve 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com