Pincer head resetting mechanism of open type power pincers

A reset mechanism and power tong technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of rapid wear, inconvenient switching and reset, etc., and achieve the effects of reducing wear, reasonable structure, and convenient switching and reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

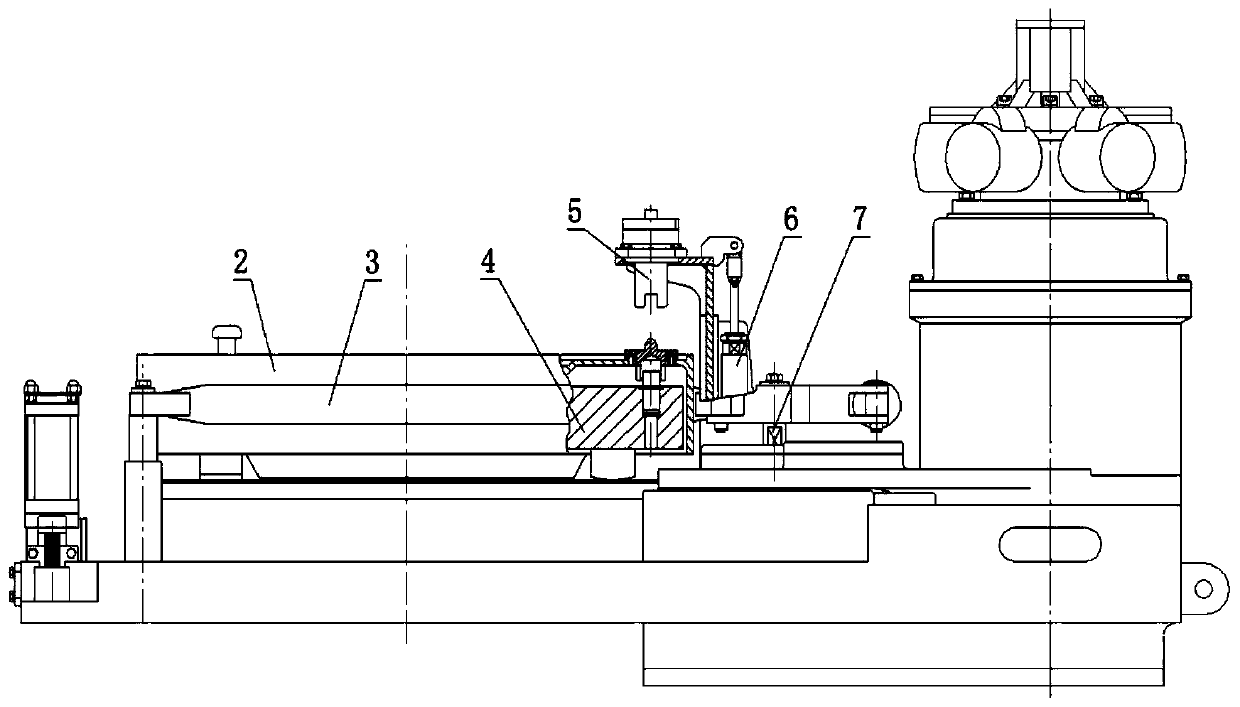

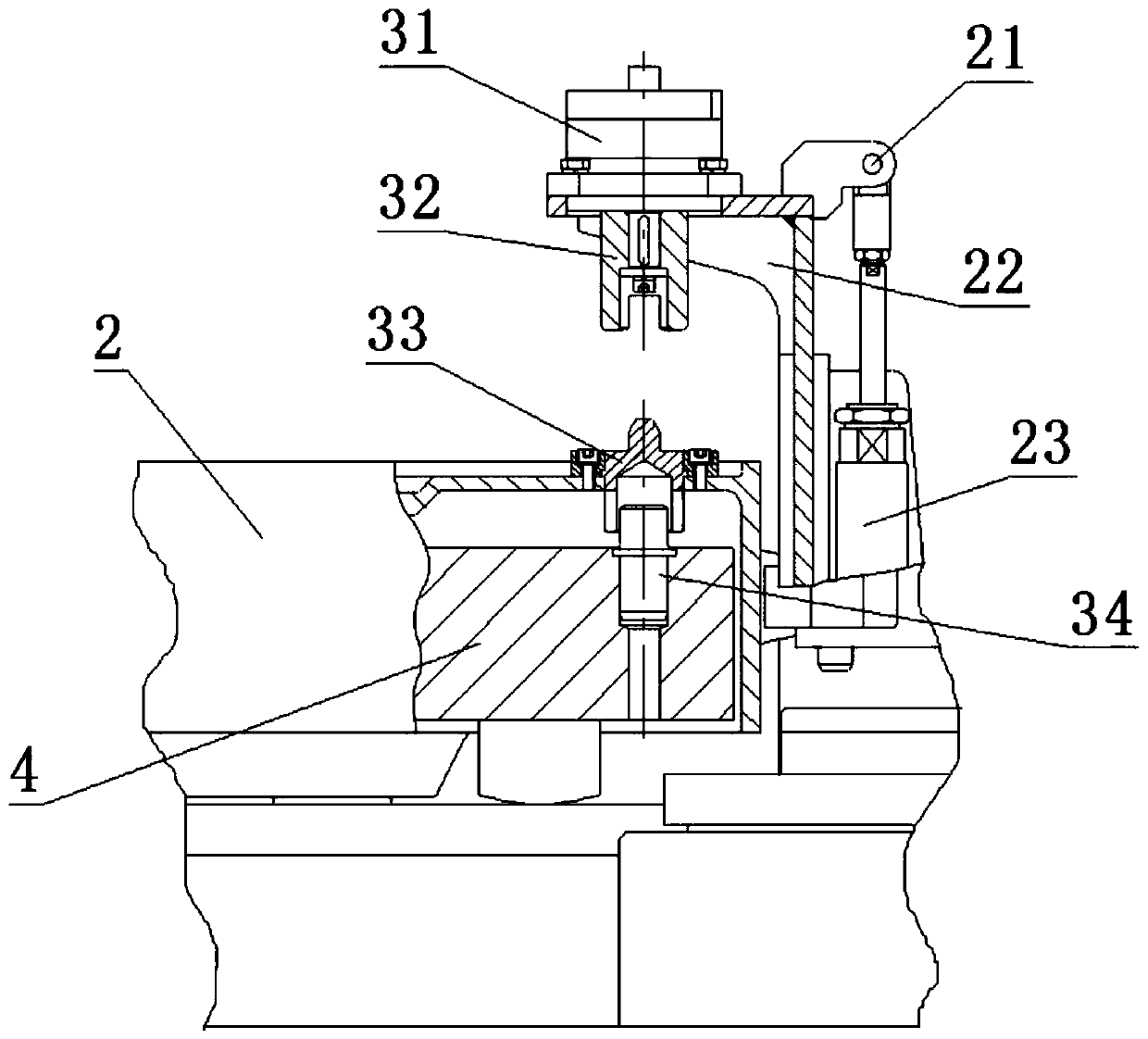

[0016] Such as figure 1 As shown, the present invention proposes a pincer head resetting mechanism of an open-type power tong, including a rotary mechanism 5, a lifting mechanism 6, and a braking mechanism 3. The lifting mechanism 6 is installed on the body of the power tong, and the lifting mechanism 6 and the power tong The brake disc 2 and the floating body 4 are all connected with the slewing mechanism 5, and the brake disc 2 on the power caliper and the brake band fixing column 7 are all connected with the brake mechanism 3.

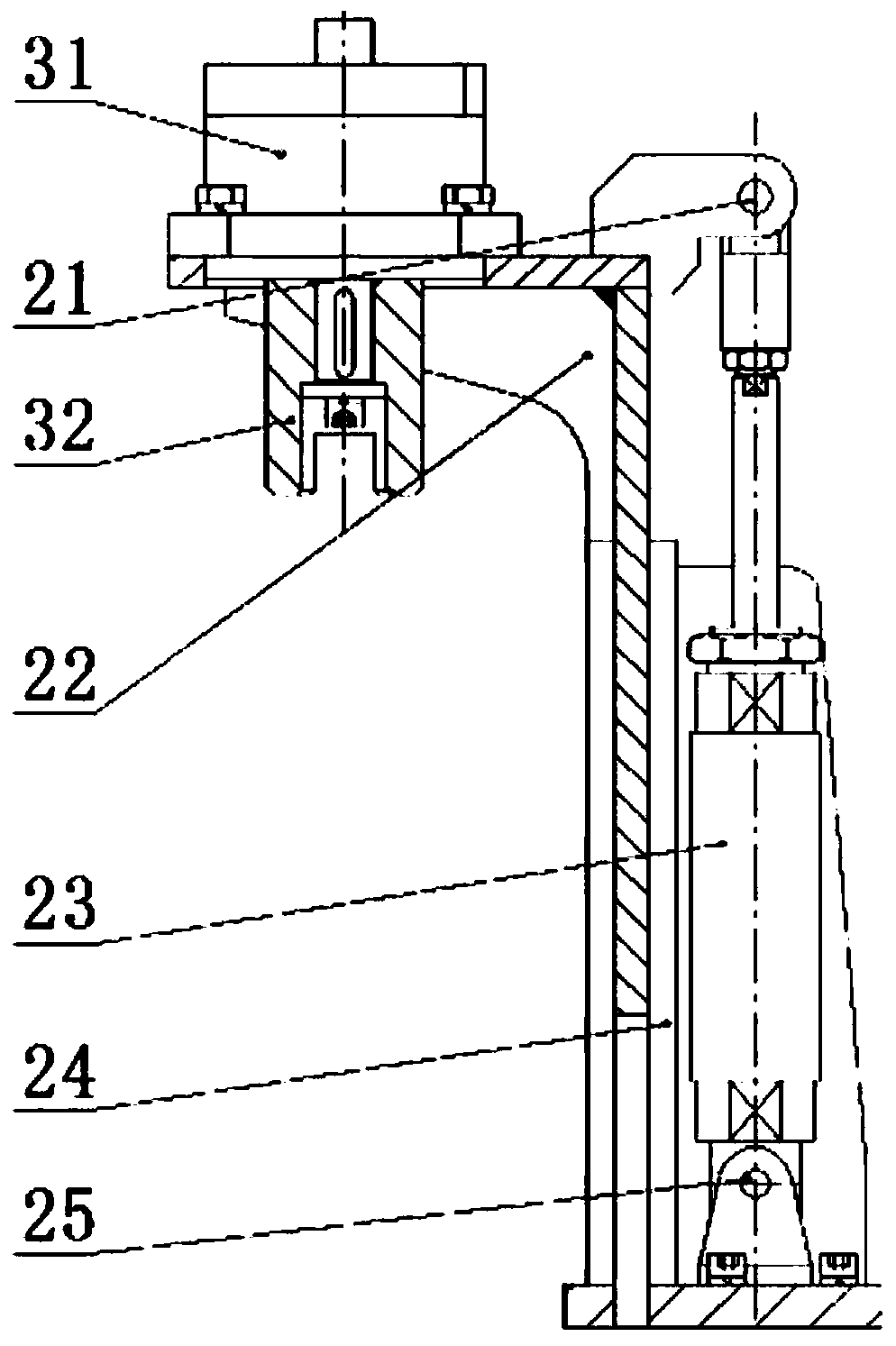

[0017] Among them, such as image 3 As shown, the lifting mechanism 6 includes a lifting slide frame 22, a lifting cylinder 23 and a guide bracket 24. The guide bracket 24 is fixedly mounted on the body of the power tong, and the guide bracket 24 is provided with a sliding groove. In the groove, the lifting cylinder 23 connects the lifting slide frame 22 and the guide bracket 24 through the upper hinge pin 21 and the lower hinge pin 25, and the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com