A thimble type micro-pulse applying device

An application device and thimble-type micro-technology, which is applied in the field of precision mechanics, can solve the problems of poor stability, large resistance, and inability to accurately adjust the size of the micro-impulse applied, and achieve the effect of reducing frictional damping, small resistance, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

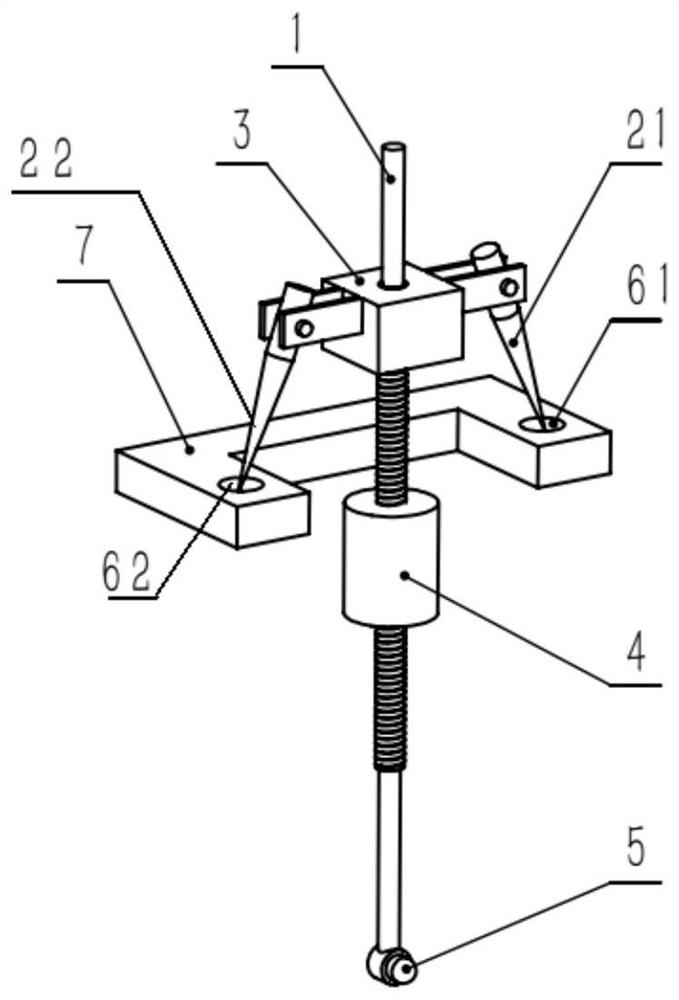

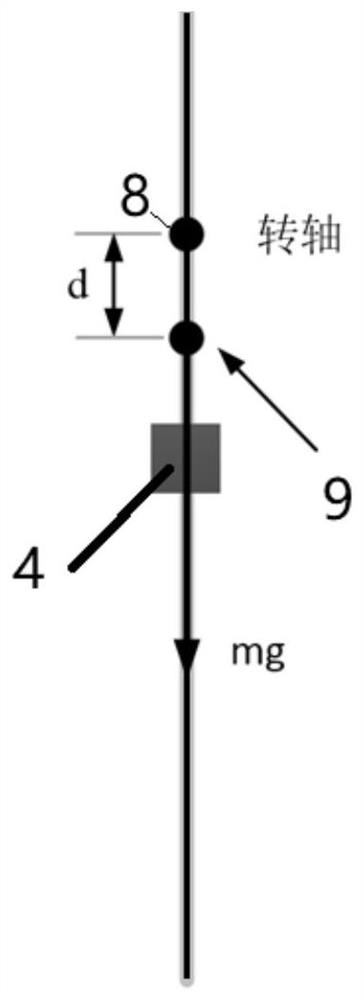

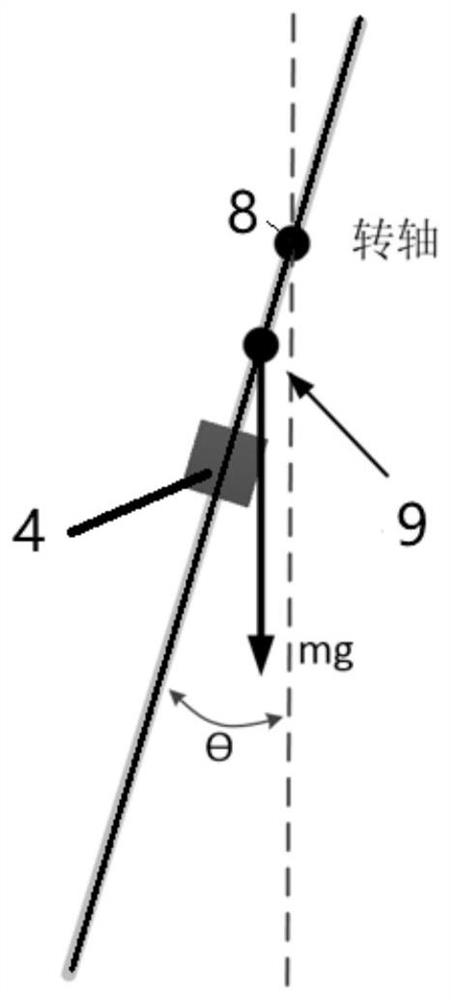

[0039] This embodiment provides a thimble type micro-pulse applying device, such as figure 1 As shown, the thimble type micro-pulse application device includes: a central rod 1, such as Figure 1~2As shown, the central rod 1 is at a balance position in a vertical position; the first thimble 21 and the second thimble 22 are symmetrically distributed with the central rod 1 as an axis. , the first thimble 21 and the second thimble 22 each have a needle point; the transfer structure 3, the transfer structure 3 connects the central rod 1 with the first thimble 21 and the second thimble 22 Fixed connection; the impact part 5, the impact part 5 is installed on the bottom of the central rod 1; the first bearing seat 61 and the second bearing seat 62, wherein: the first bearing seat 61 has a first concave arc surface , the tip of the first thimble 21 is in contact with the arc-shaped surface of the first recess, so that the first thimble 21 is placed on the first bearing seat 61, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com