Automatic cleaning device dedicated for bullet train insulator

A technology for cleaning equipment and insulators, which is applied in the field of machinery, can solve problems such as long scrubbing time, degradation of insulator insulation performance, and potential safety hazards, and achieve the effect of reducing manual output and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

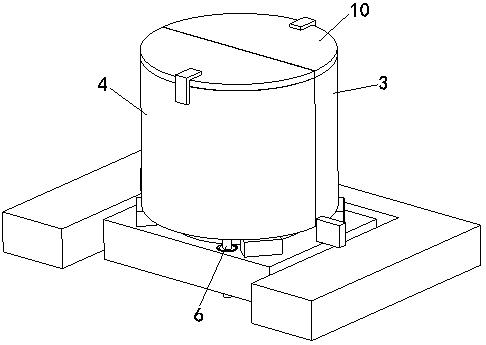

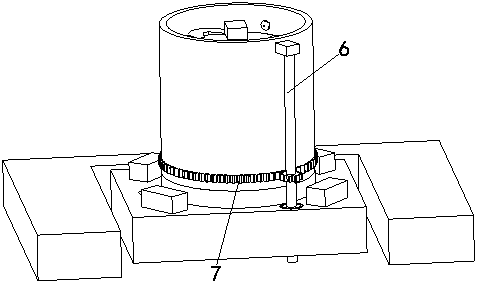

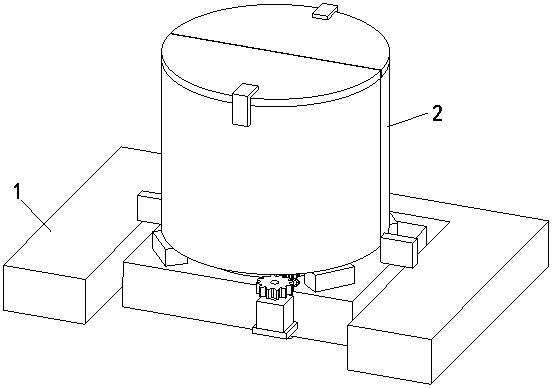

[0027] Embodiment 1: The present invention includes a card base 1, the card base 1 has a groove matching the shape of the insulator base, a cleaning cylinder 2 is fixed on the groove, and the cleaning cylinder 2 is fixed on the groove. The semi-cylinder 3 is composed of a movable semi-cylinder 4 that is movably connected with the fixed semi-cylinder 3. The ends of the fixed semi-cylinder 3 and the movable semi-cylinder have a joint closure structure that cooperates with each other. The opening of the fixed semi-cylinder 3 faces the opening of the groove. The fixed semi-cylinder 3 and the movable semi-cylinder 4 all include a semicircular shell and a semicircular inner container 5 positioned inside the outer shell, the inner container 5 and the outer shell are connected by a rotatable device, and the inner container 5 There is a cleaning device inside, at least one power gear shaft 6 is arranged between the inner tank 5 and the outer shell, and the outer wall of the inner tank 5...

Embodiment 2

[0034] Embodiment 2: The present invention includes a deck 1, the deck 1 has a groove matching the shape of the insulator base, a cleaning cylinder 2 is fixed on the groove, and the cleaning cylinder 2 is fixed on the groove. The semi-cylinder 3 is composed of a movable semi-cylinder 4 that is movably connected with the fixed semi-cylinder 3. The ends of the fixed semi-cylinder 3 and the movable semi-cylinder have a joint closure structure that cooperates with each other. The opening of the fixed semi-cylinder 3 faces the opening of the groove. The fixed semi-cylinder 3 and the movable semi-cylinder 4 all include a semicircular shell and a semicircular inner container 5 positioned inside the outer shell, the inner container 5 and the outer shell are connected by a rotatable device, and the inner container 5 There is a cleaning device inside, and three groups of rotating groups 11 that are evenly distributed around the axis of the cleaning cylinder 2 are arranged between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com