Welding method of side parts of metal inner layer, flexible middle layer and metal outer layer of variable-type ultra-thin structure

A metal outer layer, welding method technology, applied in welding equipment, welding equipment, laser welding equipment and other directions, can solve the problem of inability to achieve reliable connection, and achieve high-strength and reliable connection, good sealing, no air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

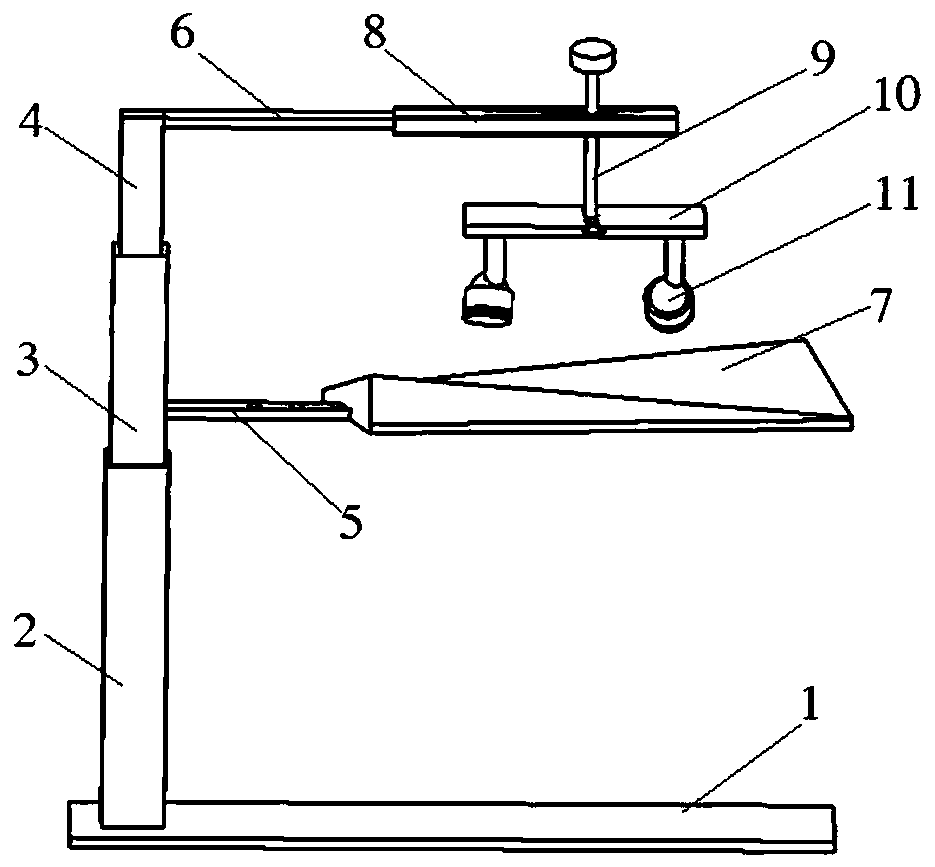

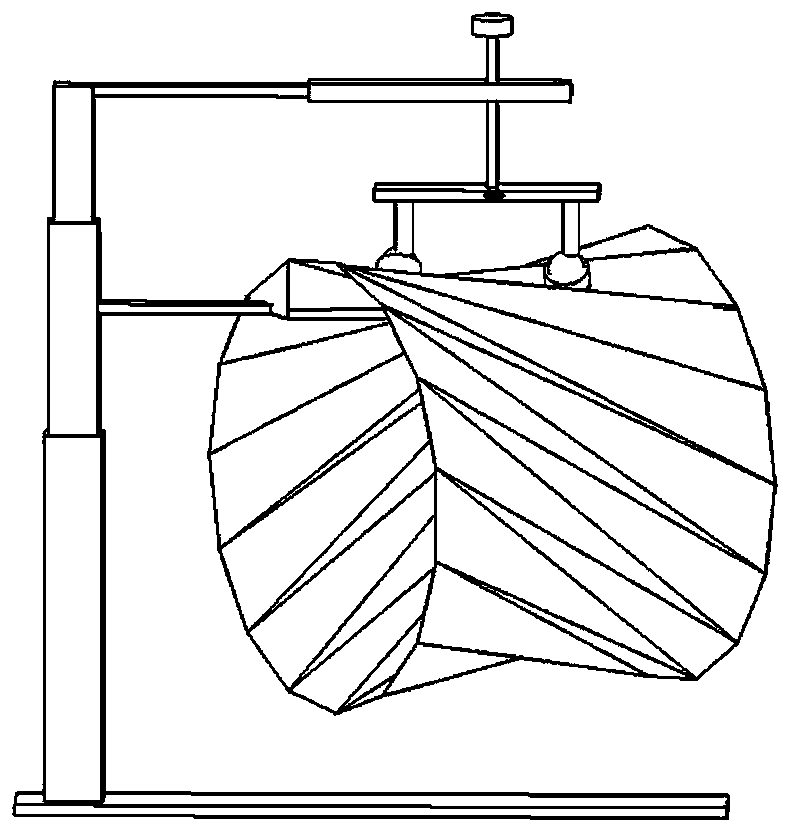

[0018] Specific implementation mode 1: This implementation mode is a welding method for the side part of the variable ultra-thin structure metal inner layer-flexible middle layer-metal outer layer, which is specifically completed according to the following steps:

[0019] 1. Metal inner layer welding: use clamps to clamp the metal inner layer joint of the variable ultra-thin structure, and then use laser to weld the weld seam of the metal inner layer joint to obtain the variable ultra-thin structure of the metal inner layer welding;

[0020] 2. Wrapping the flexible middle layer: Wrapping the flexible middle layer on the outer surface of the metal inner layer of the variable-shaped ultra-thin structure welded to the metal inner layer, that is, completing the variable-shaped ultra-thin structure of the wrapped flexible middle layer;

[0021] 3. Welding of the metal outer layer: first wrap the metal outer layer on the outer surface of the variable and ultra-thin flexible middle l...

specific Embodiment approach 2

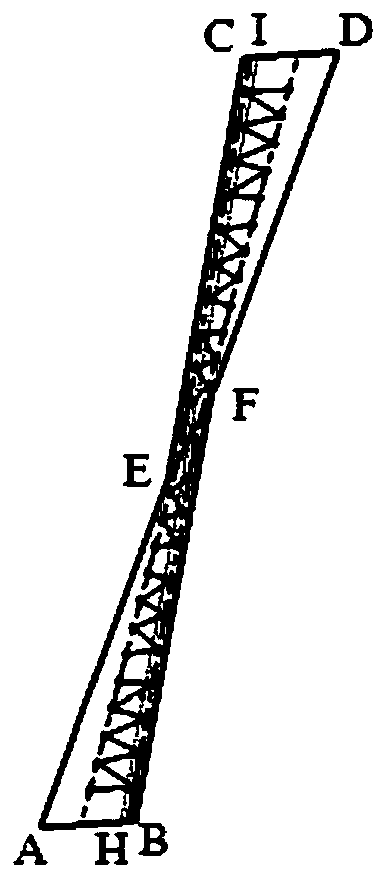

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the special-shaped foil gasket described in step 3 is composed of a different quadrilateral EFBA and a different quadrilateral EFDC, and the different quadrilateral EFBA and the different quadrilateral EFDC are along the center of the EF midpoint. Symmetrical, the weld crease coincides with EF, and FB and EC are guaranteed to be parallel to the weld of the metal outer joint. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the special-shaped foil gasket in step 3 is made of 304 stainless steel. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com