An overflow brick structure adapting to high temperature creep

A technology of high-temperature creep and overflow bricks, which is applied in the direction of manufacturing tools, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of production process influence, meet the production requirements of the process, control the flow distribution stably, and solve the key forming The effect of equipment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

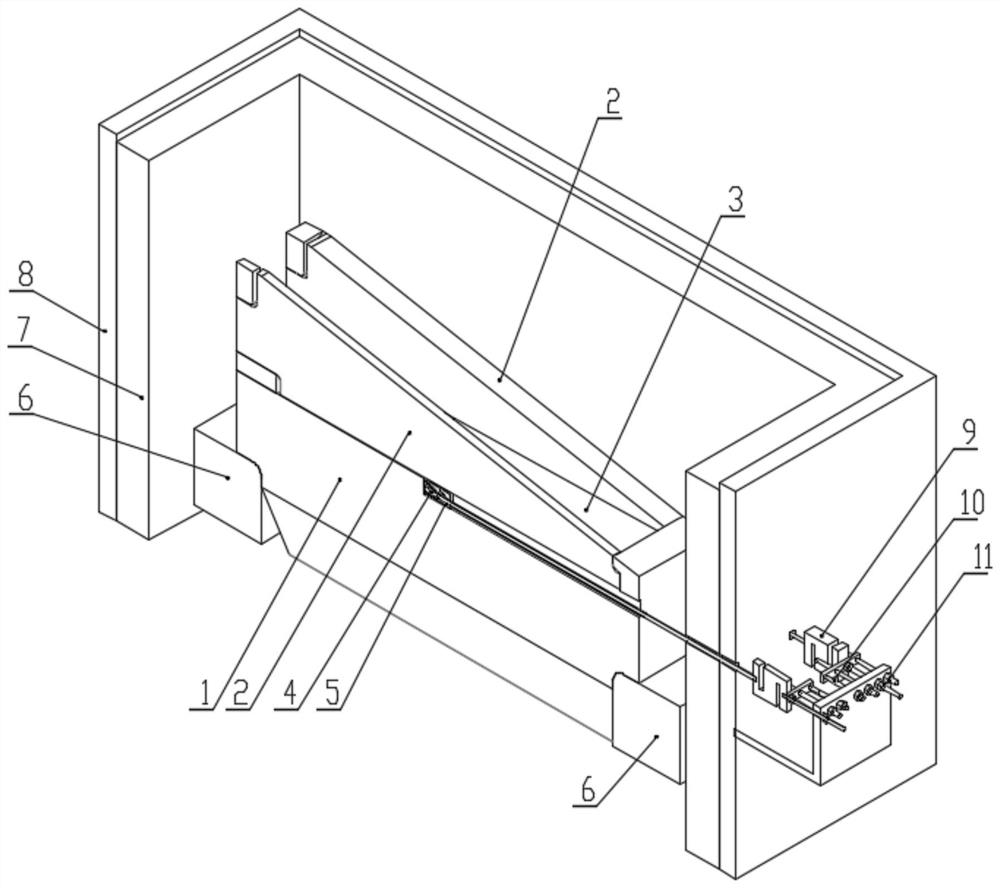

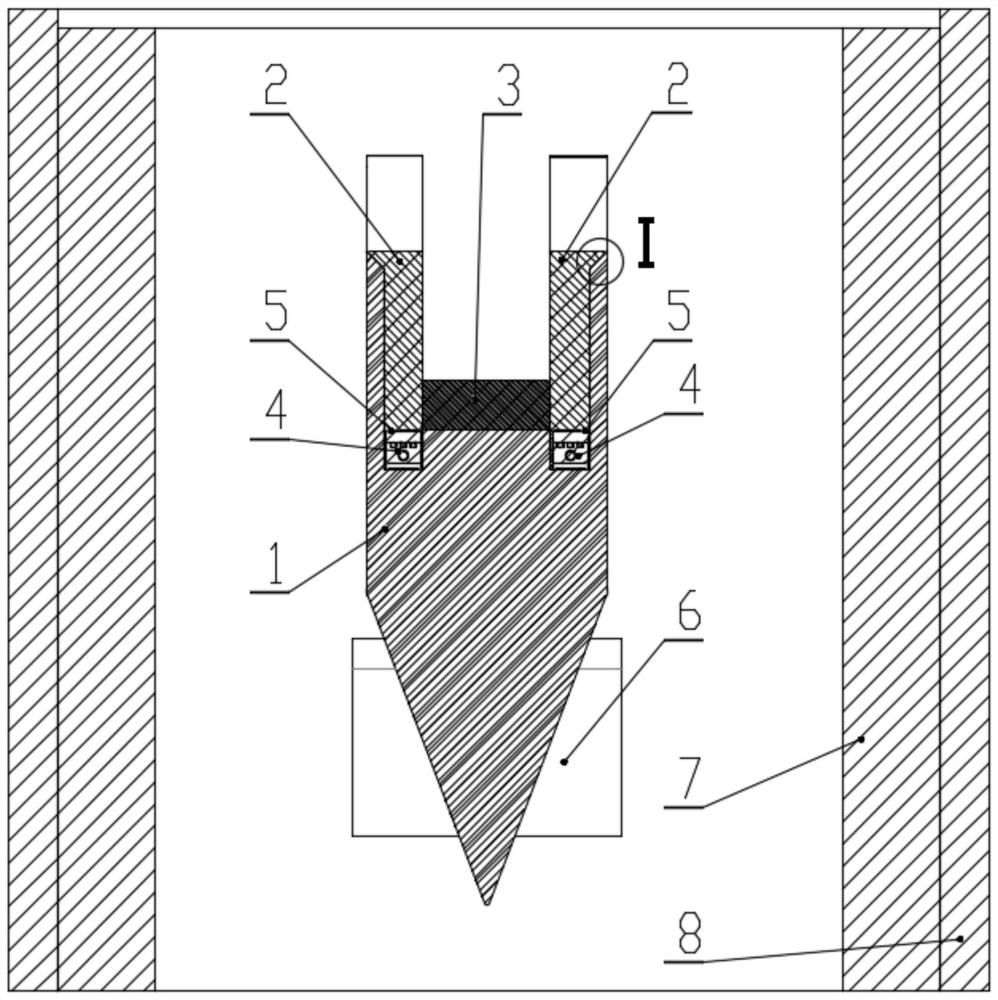

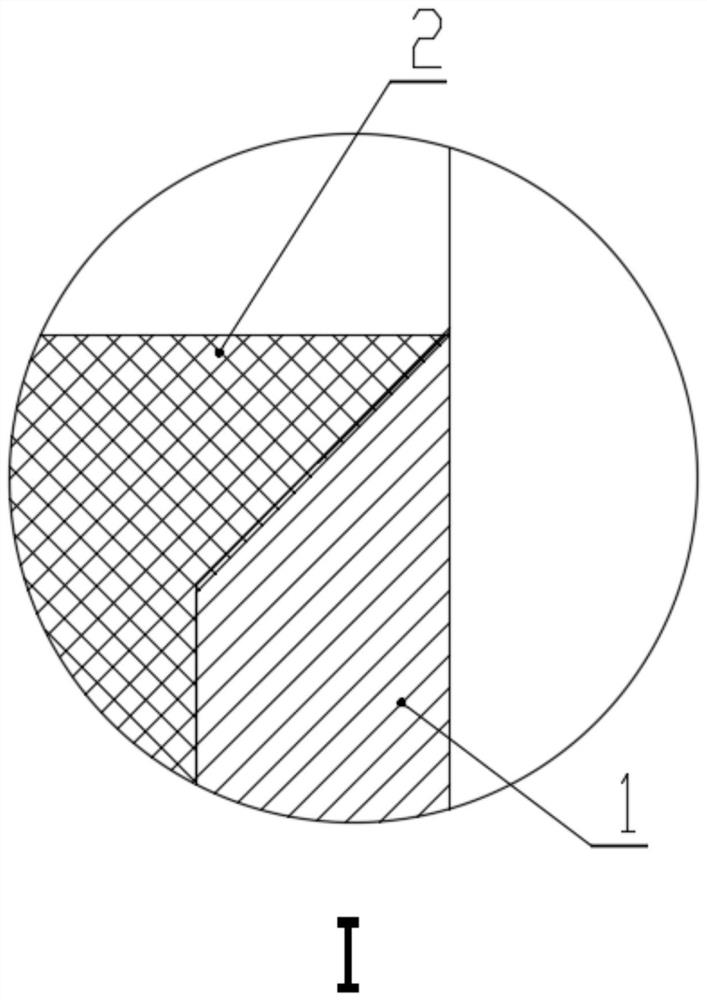

[0039] like figure 1 As shown, in this embodiment, an overflow brick structure adapted to high temperature creep is specifically provided, and the structure is suitable for a horse boiler steel structure. The horse boiler steel structure includes an outer steel structure 8 and an inner brick structure 7. In the horse boiler steel structure The structure includes overflow bricks 1 , and both ends of the overflow bricks 1 are mounted on support bricks 6 and provided with supporting force through the support bricks 6 . An overflow sill 2 is inlaid in the inner cavity of the overflow brick 1. The two ends of the overflow sill 2 are provided with a limiting structure that provides a limiting force to it, and a support adjustment that provides a supporting force is provided in the middle. Structure, the limit force and support force are both located in the straight line direction of the overflow brick 1 sinking through high temperature creep. Under the combined action of the limit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com