Lead screw sliding rail with lubricating oil path

A technology of lubricating oil circuit and lead screw, applied in the field of lead screw transmission mechanism, can solve the problems of complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

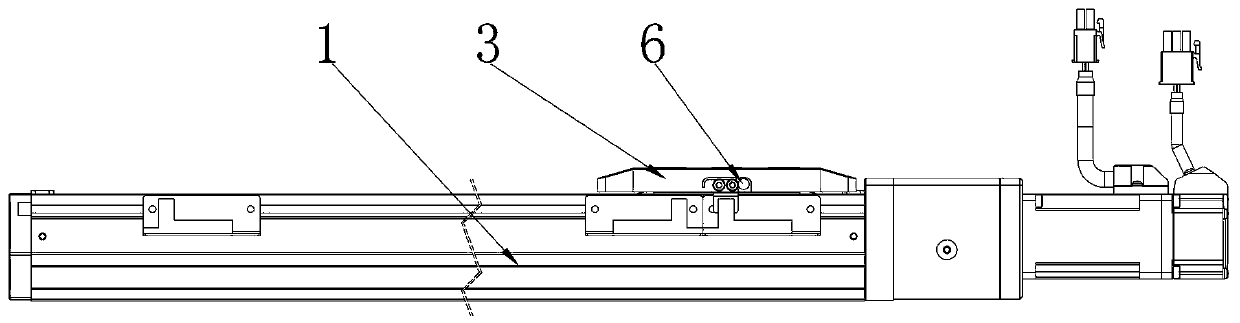

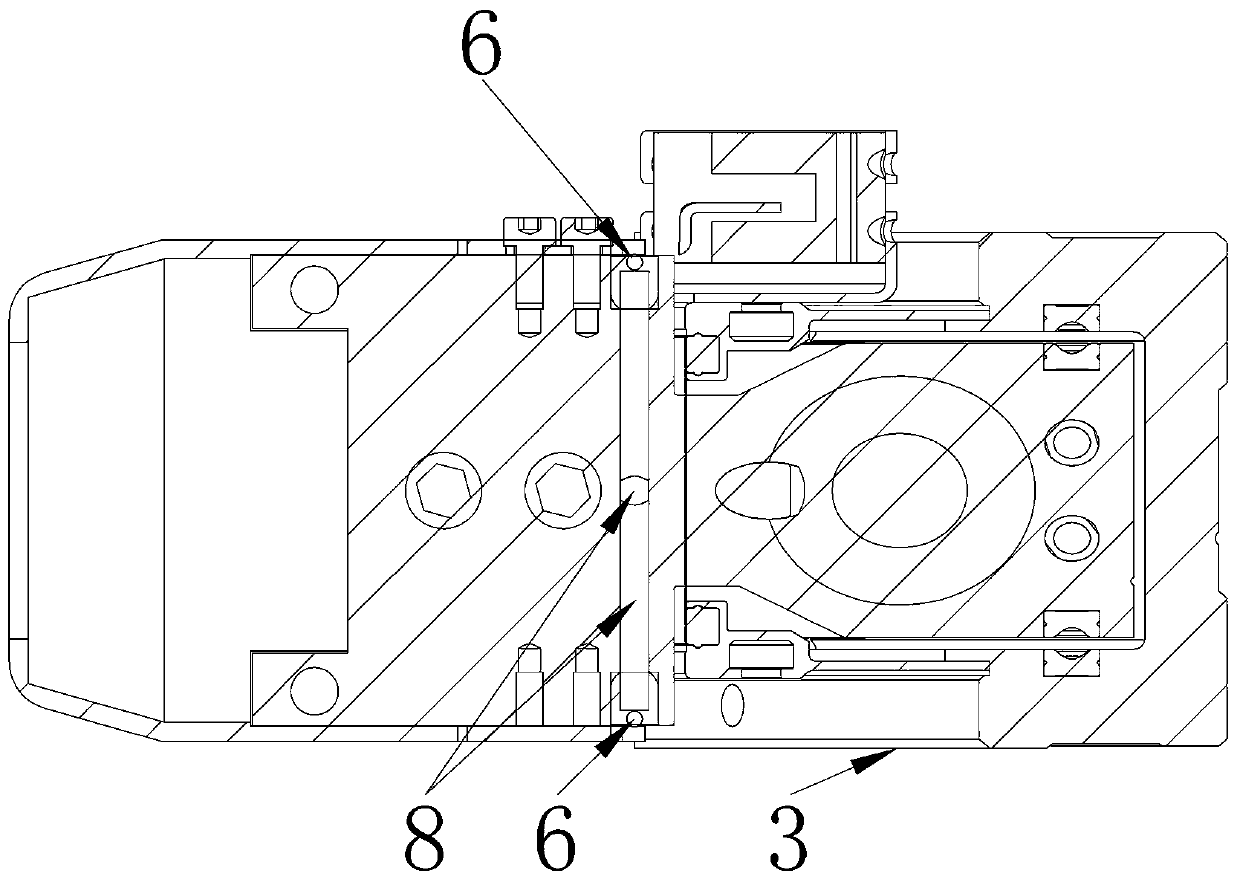

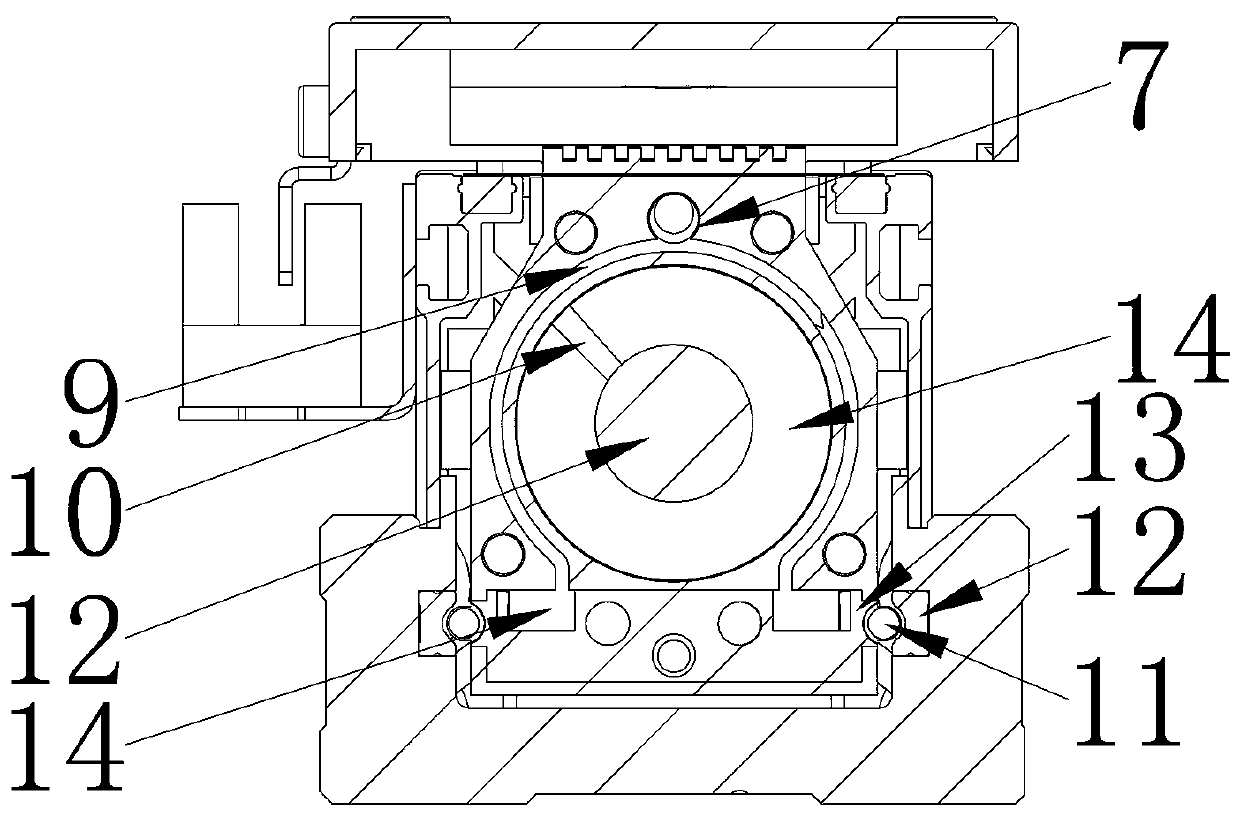

[0013] Such as Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes a sliding seat 1, a screw 2 and a slider 3, the screw 2 is rotatably fitted in the sliding seat 1, and the sliding block 3 and the sliding seat 1 Sliding fit, the slider 3 is provided with a screw nut 4 that is compatible with the lead screw 2, and the top of the slider 1 is provided with a cover sheet that cooperates with the slider 3, and the slider 3 is provided with a fixed block 5, the screw nut 4 is fixed in the fixed block 5, the side end of the slider 3 is provided with an oil injection hole 6, and the fixed block 5 is provided with an oil inlet chamber 7. The oil injection hole 6 communicates with the oil inlet chamber 7 through the oil delivery channel 8, the outer wall of the screw nut 4 is provided with an oil guide groove 9, and the bottom of the oil inlet chamber 7 is connected to the oil guide groove 9 The upper half of the oil guide groove 9 is provided with a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com