Valve seat structure of ultralow temperature top assembling type ball valve

A top-mounted, ultra-low temperature technology, applied in the direction of valve devices, connecting components, cocks including cut-off devices, etc., can solve the problems of immature and difficult key technologies, and achieve the advantages of easy assembly, improved reliability, and anti-rotation problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

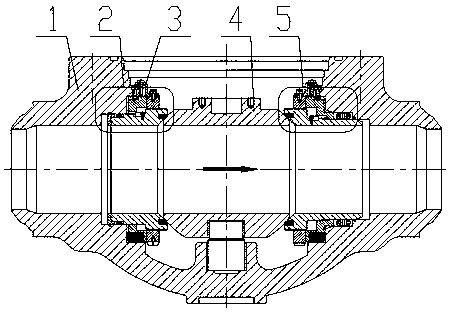

[0015] refer to figure 1 , a seat structure of an ultra-low temperature top-entry ball valve, comprising a valve body 1, a ball 4 is arranged in the middle of the valve body 1, an upstream seat assembly 2 and a downstream seat assembly 5 are arranged on both sides of the ball 4, and the upstream seat assembly 2 and the downstream valve seat assembly 5 are installed symmetrically, wherein the upstream valve seat is a one-way sealing structure, and the downstream valve seat is a two-way sealing structure. The upstream and downstream valve seat components mainly include a valve seat and a spring seat and a positioning nut installed on the valve seat. The medium in the ultra-low temperature top-entry ball valve has flow direction requirements. It is a DIB-2 seat structure and has a self-relieving function in the middle cavity.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com