Interlocking type bolt anti-loosening structure

An anti-loose and bolt technology, applied in the direction of bolts, screws, nuts, etc., can solve the problem of loose bolt connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

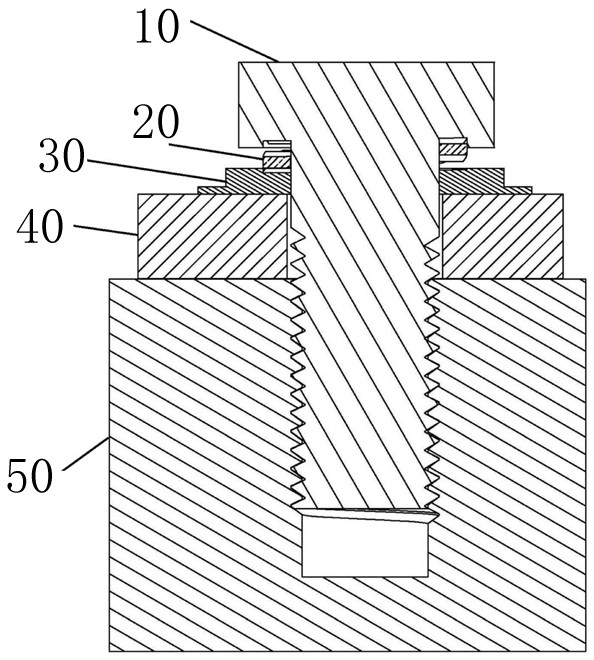

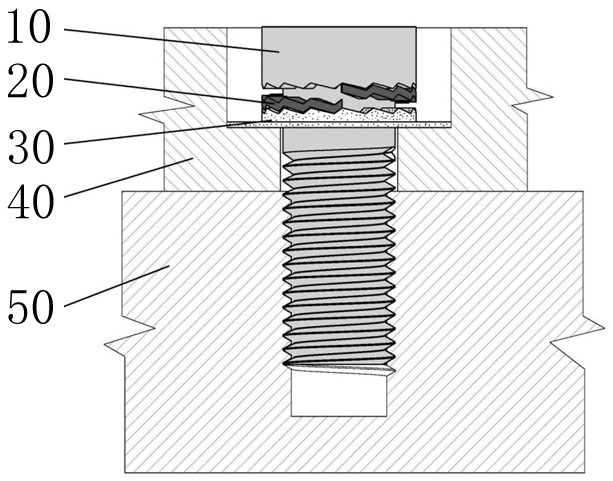

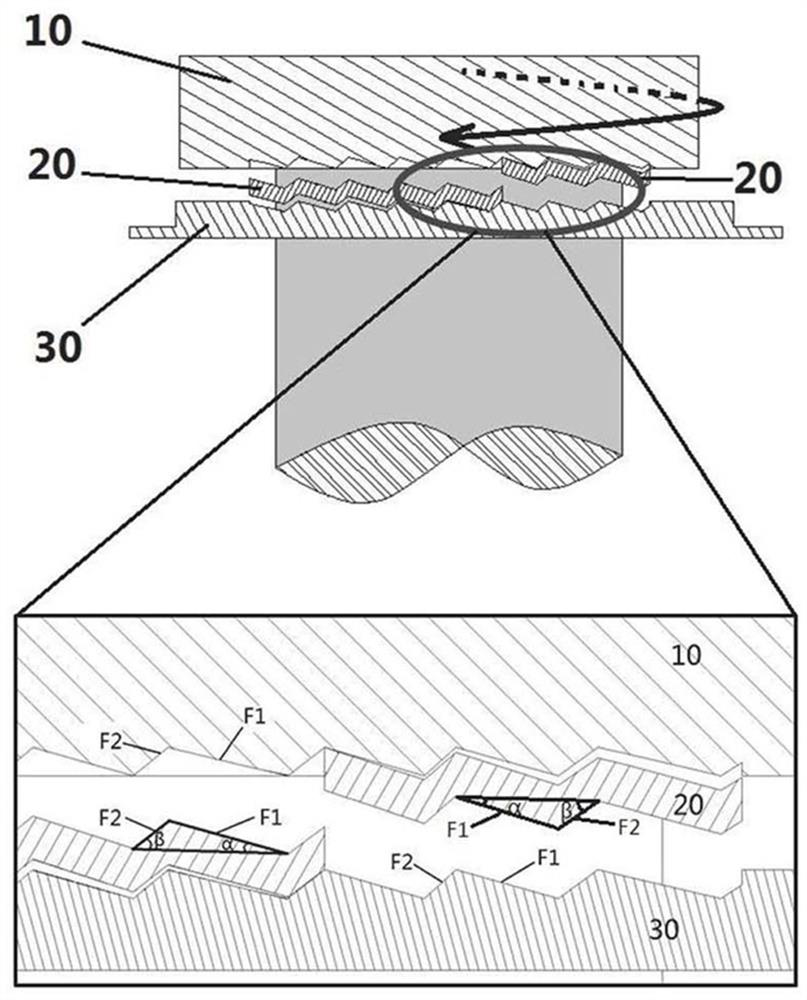

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0025] It should be noted:

[0026] The critical angle θ refers to the minimum slope or angle required for the anti-loosening surfaces of the anti-loosening teeth to fail to slide relative to each other due to mutual resistance when loosening occurs due to vibration;

[0027] The uphill tangent direction refers to the direction from the root of the anti-loosening tooth to the top of the tooth;

[0028] The slope refers to the angle between the uphill tangent of the point on the guide surface or the anti-loosening surface and the vertical plane of the central axis;

[0029] The helix angle of the elastic anti-loosening ring is greater than the lead angle of the same-handed thread, and the lead angle and helix angle have the same regulations as the terms of the thread in the machine.

[0030] The present invention as Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com