Wiring device for power construction

A wiring device and power construction technology, applied in circuits, connections, electrical components, etc., can solve the problems of low work efficiency, large workload, and unfavorable conductive efficiency of wires, and achieve good wiring effect, fast wiring speed, and mutual articulation process. Smooth and unobstructed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

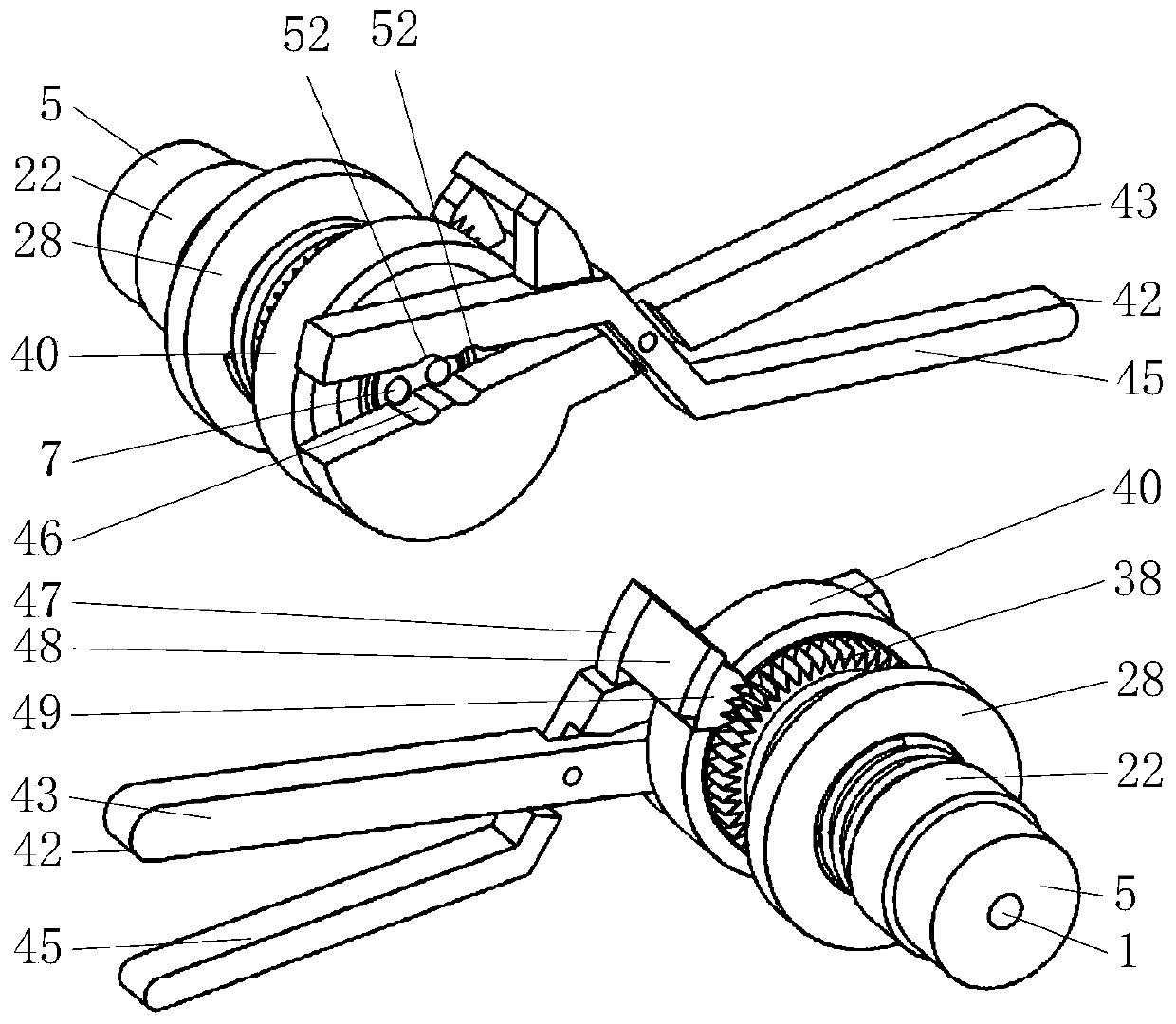

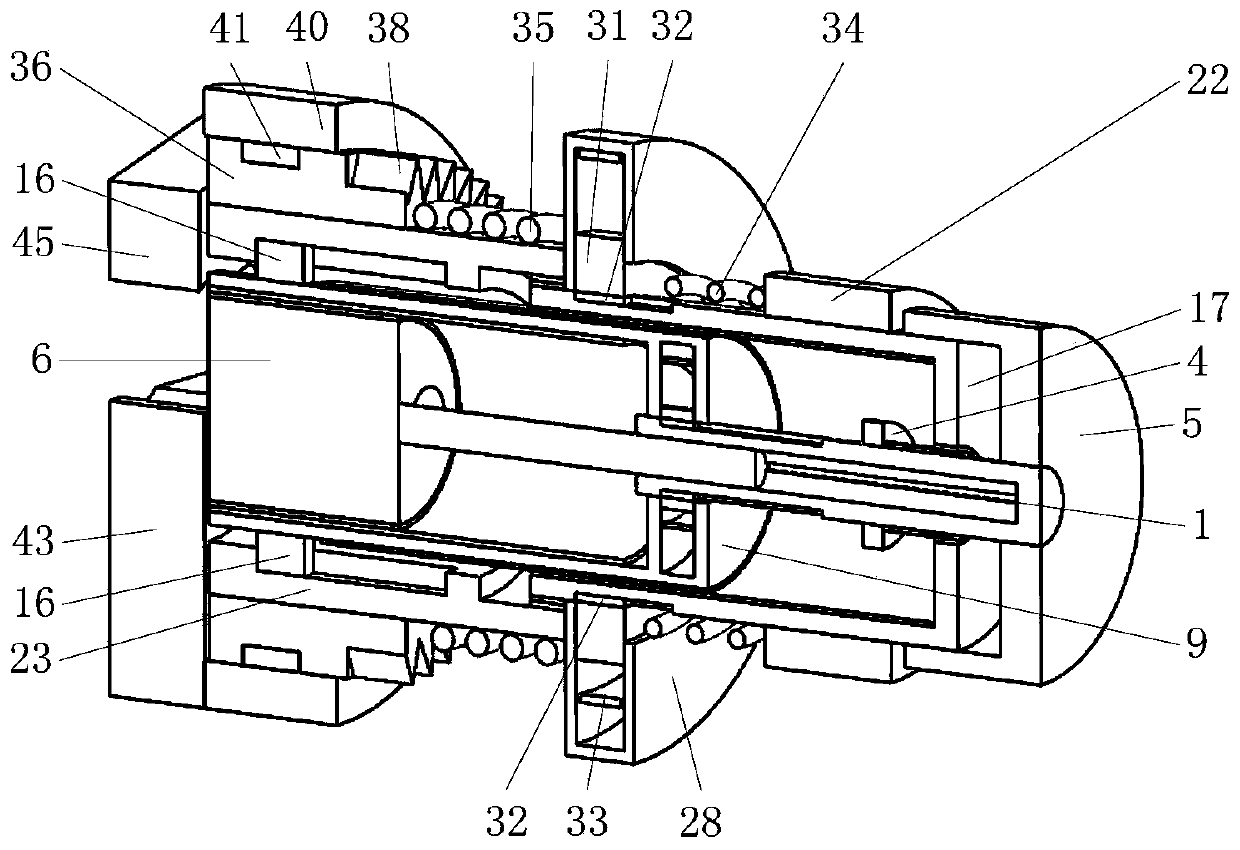

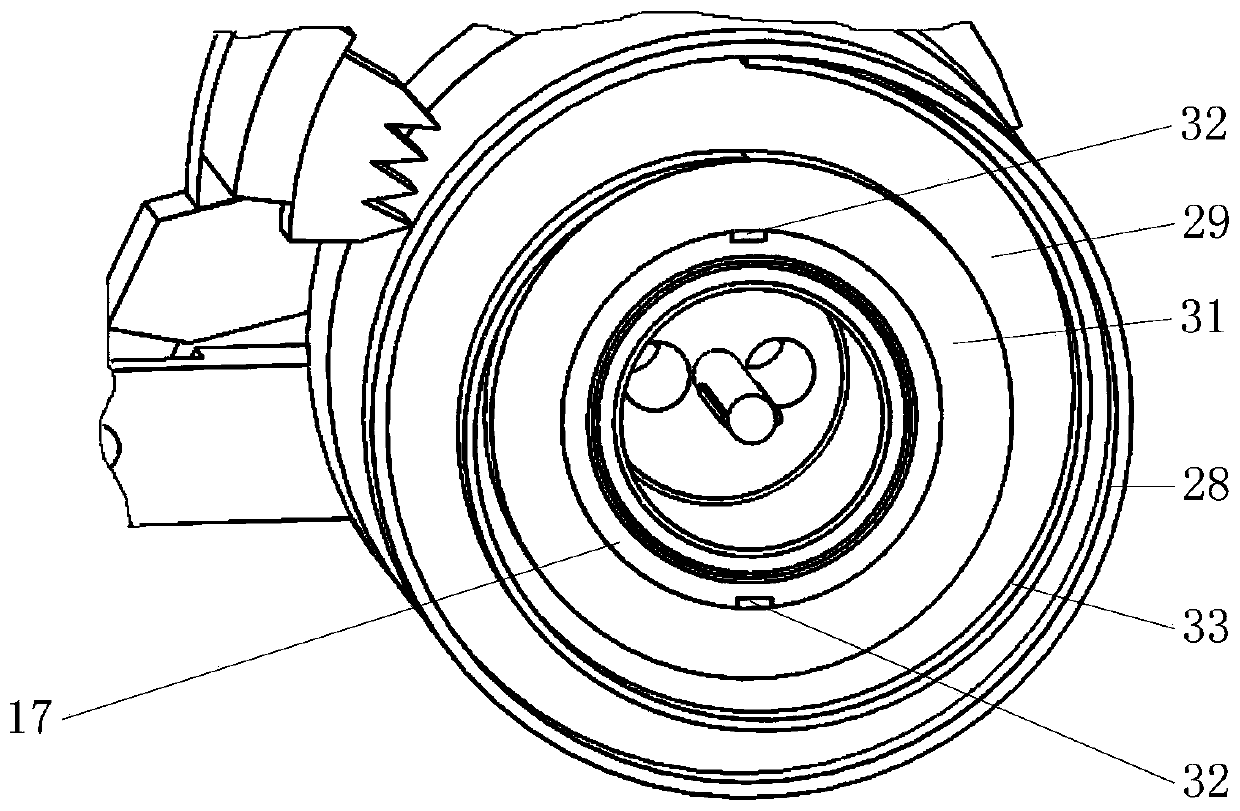

[0038] Such as figure 1 , 2 , 10, it includes telescopic shaft 1, ring A4, twist wheel 5, strand post 6, strand hole 7, drum A9, ring B13, scroll spring A15, drum B17, ring C22, cylindrical tube 23. Ring D28, ring groove D29, circular groove 30, ring E31, scroll spring B33, return spring A34, return spring B35, ring F36, limit tooth A38, ring G40, clamping mechanism 42, among which Figure 5 As shown, the internal thread A11 on the inner cylinder of the barrel A9 is threaded with the external thread B8 on the outer cylinder of the strand post 6; Figure 5 , 15 As shown, the outer shaft of the telescopic shaft 1 rotates and slides in the circular hole at the bottom center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com