Redundant motor and its assembling method

A redundant, electromagnetic field technology, applied in electromechanical devices, electric steering mechanisms, electrical components, etc., can solve the problem of inability to realize the double shift of the electromagnetic field in the motor space, and achieve the effect of easy replacement and maintenance, easy wiring, and elimination of torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

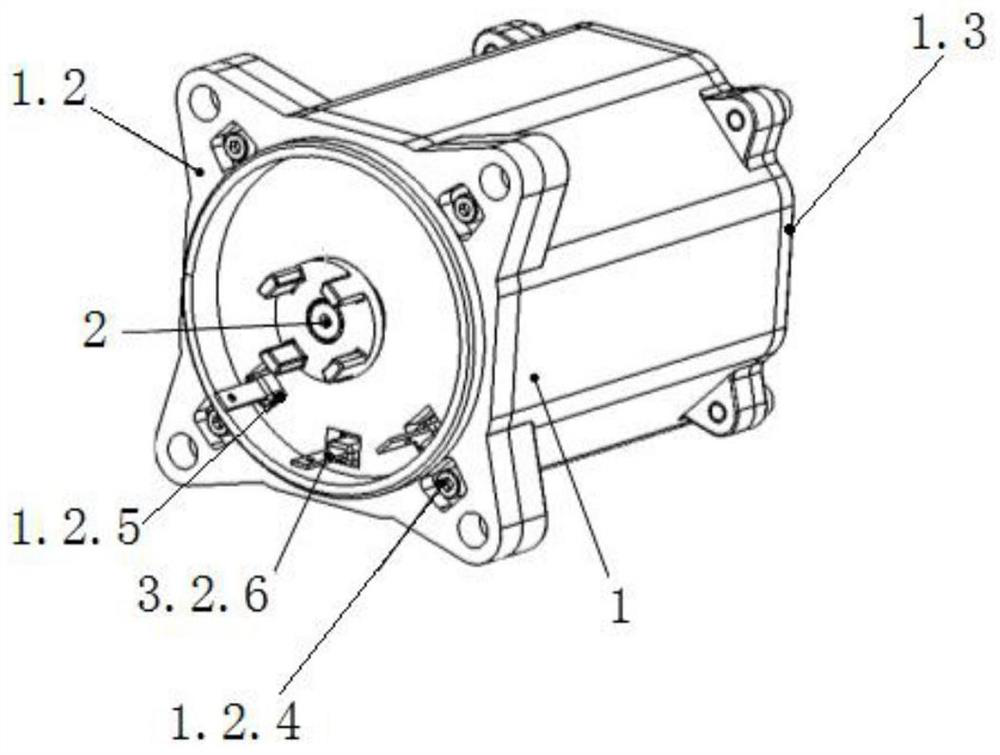

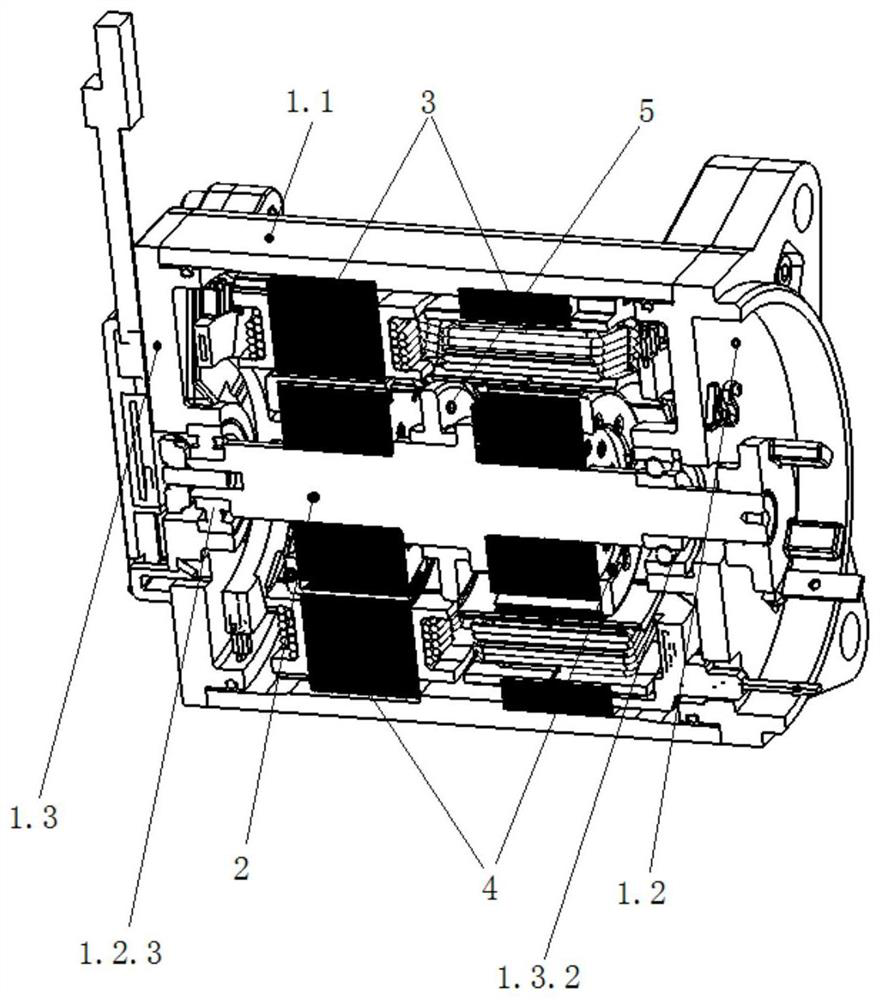

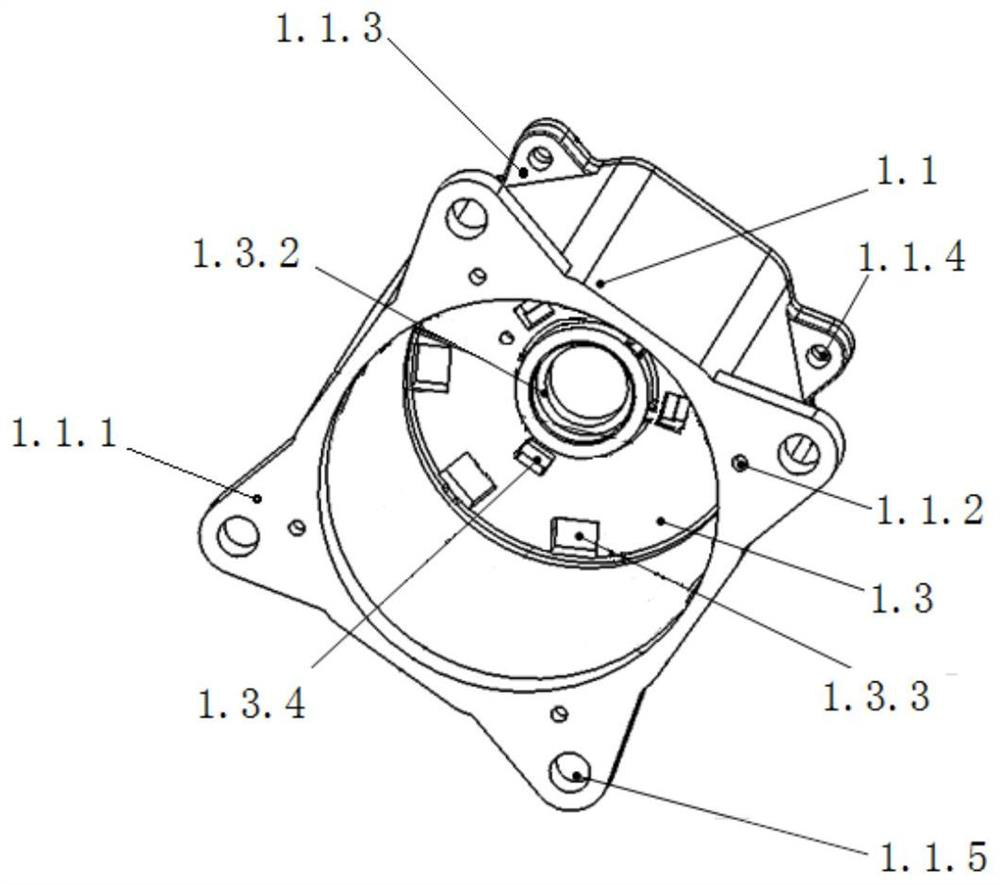

[0198] refer to figure 1 , 2 As shown, the first embodiment of the redundant motor provided by the present invention includes:

[0199] Housing 1, the front end cover and the rear end cover are respectively provided with a first bearing 1.2.3 and a second bearing 1.3.2, which are used to accommodate the rotating shaft, redundant stator assembly, redundant rotor assembly and magnetic isolation parts;

[0200] Rotating shaft 2, the two ends of which are passed through the bearings of the front end cover and the rear end cover of the housing, and redundant rotor assemblies are respectively fixed on both sides of the shaft shoulder;

[0201] Redundant stator assemblies 3, which are respectively fixed in the housing;

[0202] Redundant rotor assembly 4, which passes through the stator assembly together with the rotating shaft, and is respectively located in the redundant stator assembly;

[0203] A magnetic spacer 5, which is fixed on the shaft between the redundant rotor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com