Embedded magnetic path structure of high-performance permanent-magnet synchronous servo motor rotor

A permanent magnet synchronous, servo motor technology, applied in the field of servo motors, can solve the problems of high magnetic steel temperature, narrow speed regulation range, low power density and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

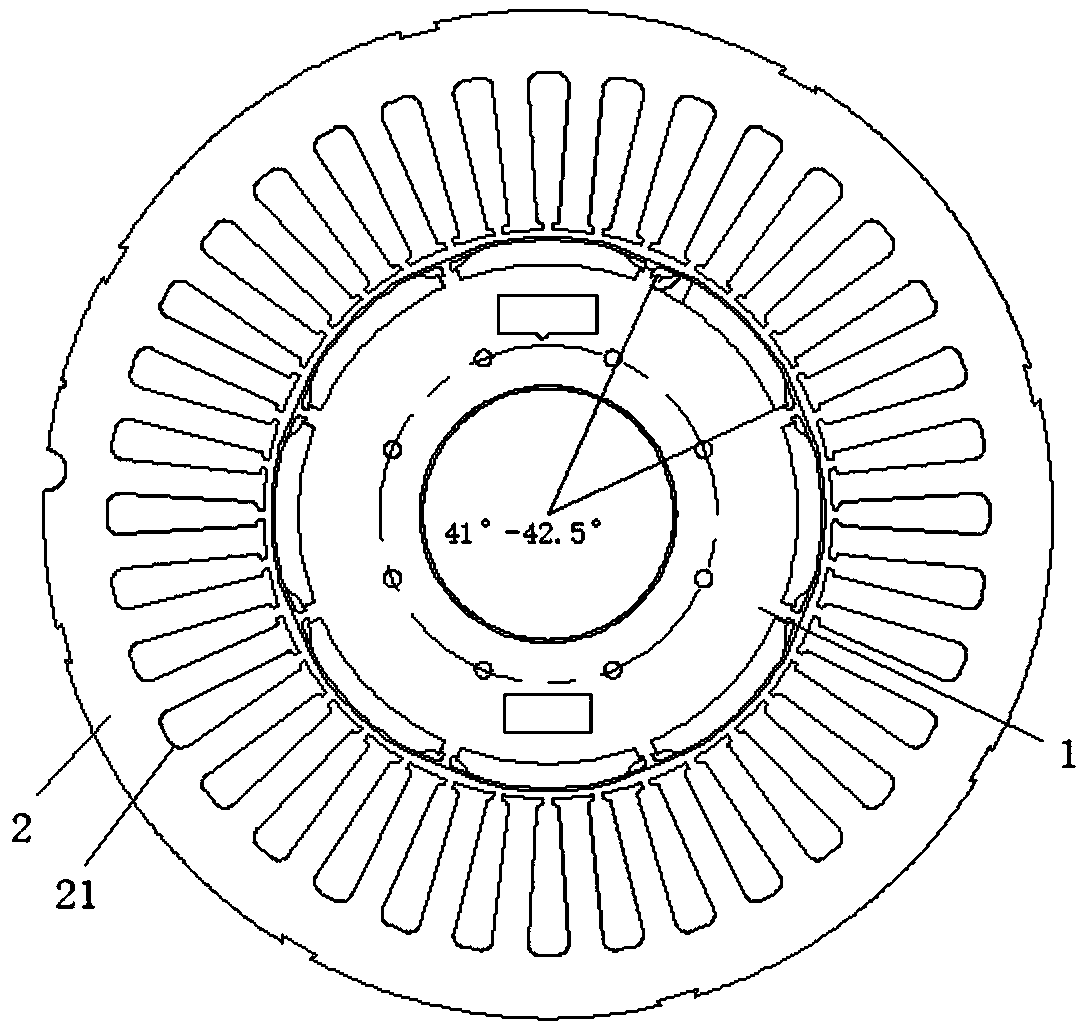

[0021] refer to Figure 1-4 As shown, this embodiment is a high-performance permanent magnet synchronous servo motor rotor embedded magnetic circuit structure, including a rotor punch 1, a stator punch 2 arranged on the outer periphery of the rotor punch 1, and a magnet set in the rotor punch 2. steel components;

[0022] There is an annular vacancy 11 between the rotor punch 1 and the stator punch 2; the inner circumference of the stator punch 2 is provided with a number of slots 21 for accommodating coils arranged at equidistant intervals, and the ends of each slot 21 are in contact with the vacancy 11. connected.

[0023] The rotor punch 1 includes an annular rotor core 3 and a plurality of holes 31 arranged at equal intervals on the outer periphery of the rotor core 3 .

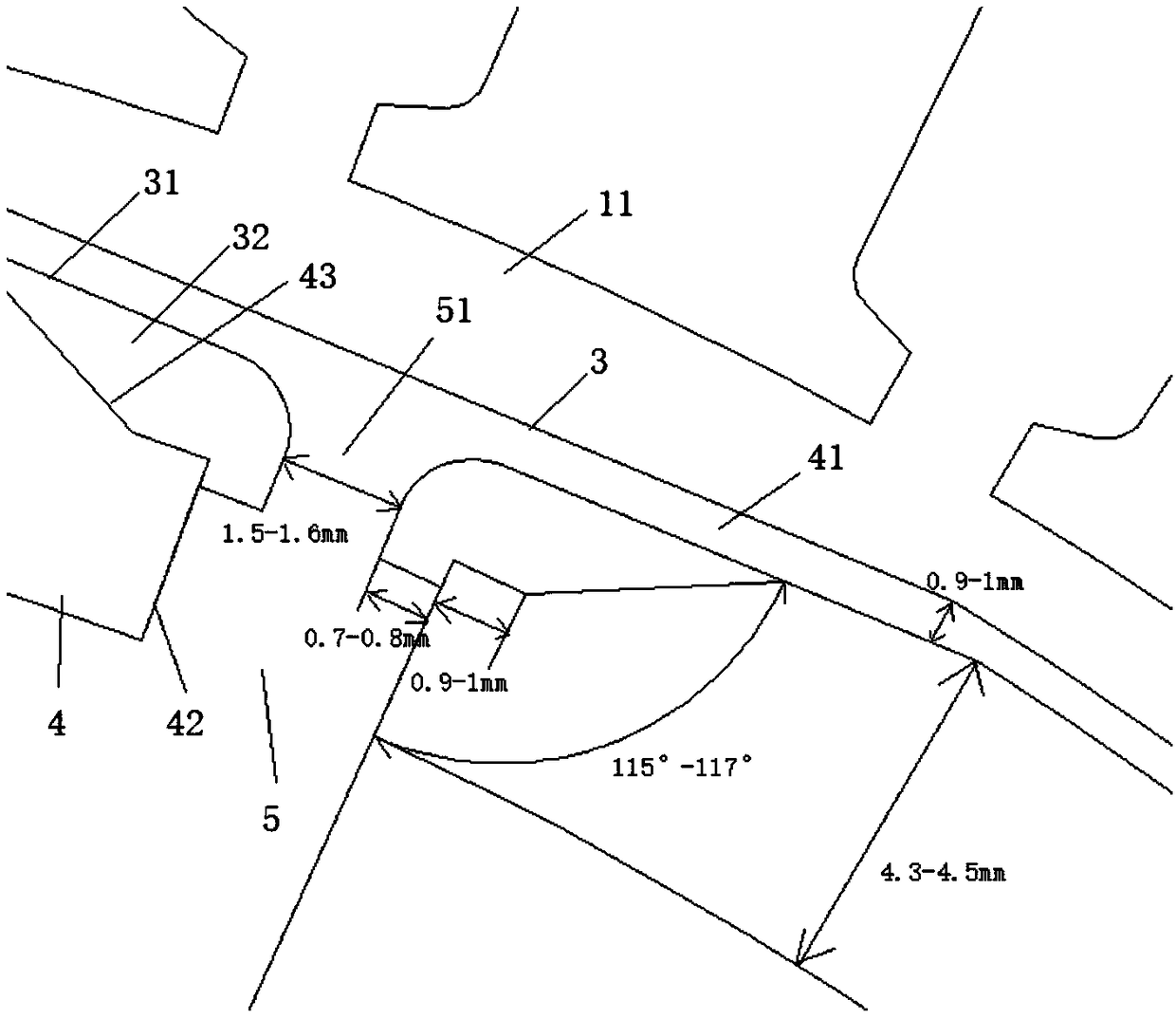

[0024] The magnetic steel assembly includes the magnetic steel 4 arranged in the hole 31, the magnetic spacer bridge arranged between the adjacent holes, and the rotor core bulge 41 arranged between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Zhang jiao | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com