Method for controlling synchronization and shifting

A control method and spindle technology, applied in transmission control, transportation and packaging, components with teeth, etc., can solve the problems of mechanical parts wear and torque fluctuations, and achieve the elimination of torque fluctuations and avoid excessive wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

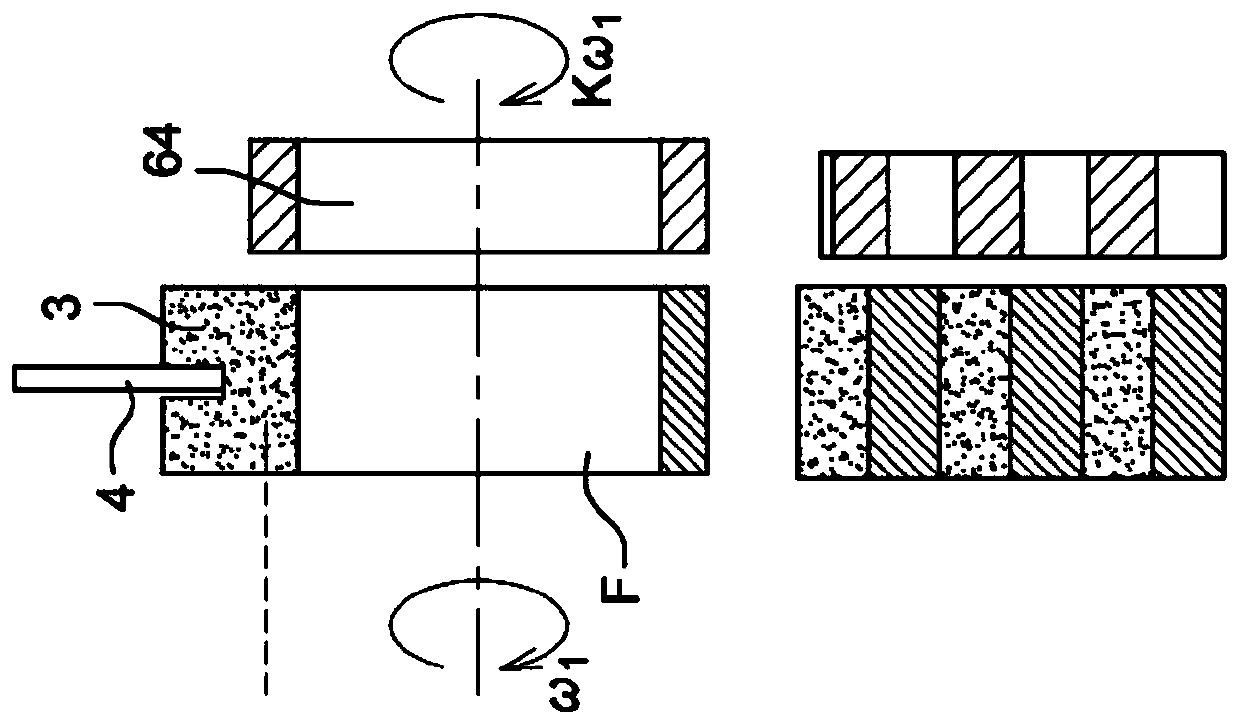

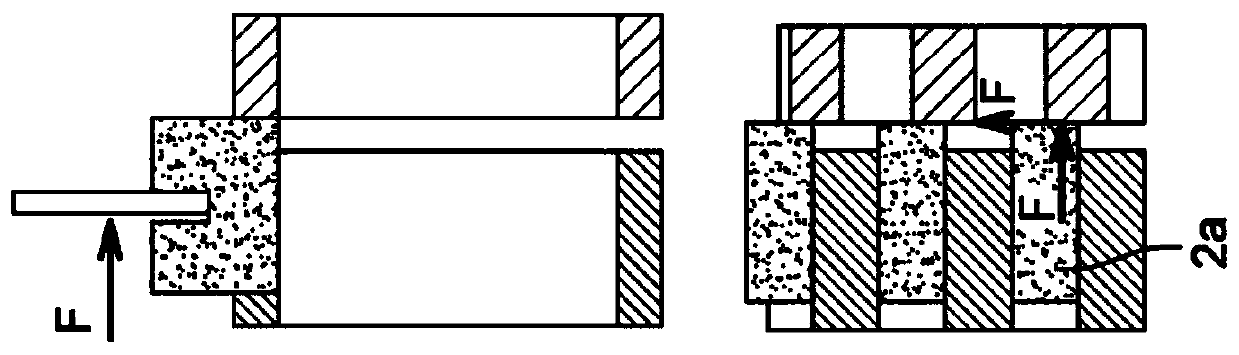

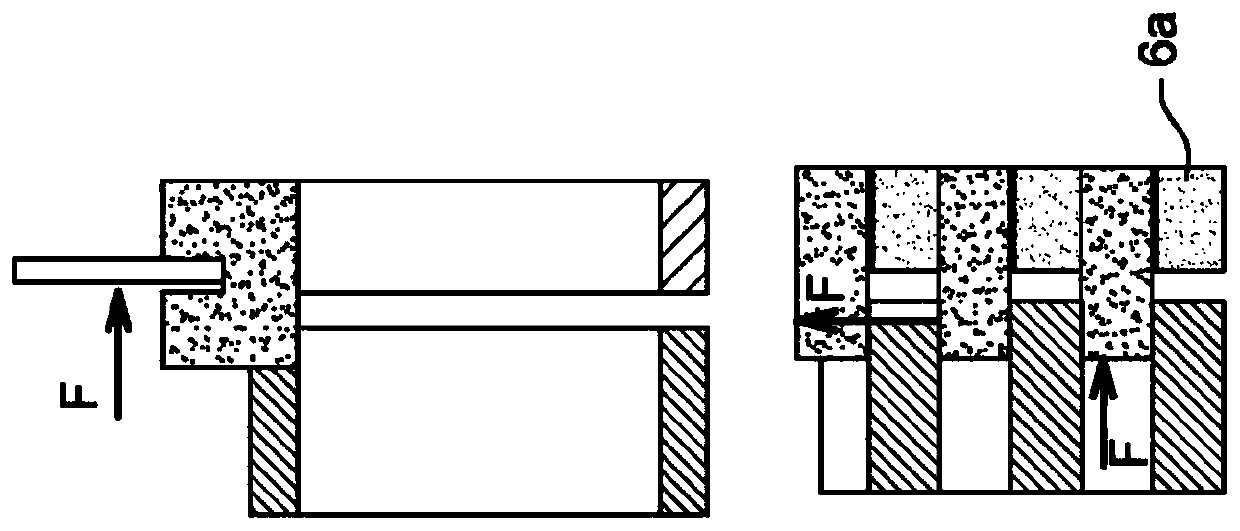

[0015] Figure 1A to Figure 1C The shift slide 2 and its sleeve 3 , its actuating fork 4 and pinion 6 are schematically shown. The lower part of these figures also shows the teeth 2a and 6a of the slide gear and pinion. Sliding gear 2 and pinion 3 are coaxial on a gearbox main shaft (not shown) connected to the vehicle's energy source (traction machine). The pinion 6 is rotationally connected to a gearbox layshaft which is connected to the wheels of the vehicle.

[0016] Figure 1A The initial state of the system at dead point is shown. Sliding gear 2 at the speed of the main shaft ω 1 to rotate. Pinion 6 at a speed ω determined by the countershaft of the gearbox 2 is rotated, the velocity is related to ω 1 different. exist Figure 1B , the slide gear 2 is moved until its teeth 2 a meet those of the pinion 6 . When their rotational speeds are equal, that is to say, at the end of the synchronous phase, the teeth of the sliding gear are interspersed between those of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com