Coloring device for production of anesthesia breathing mask

A breathing mask and shield technology, which is applied to spray devices, liquid spray devices, spray booths, etc., can solve the problems of low automation and manual operation of fixing fixtures, and achieve good clamping and fixing effect, not easy to leak, and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

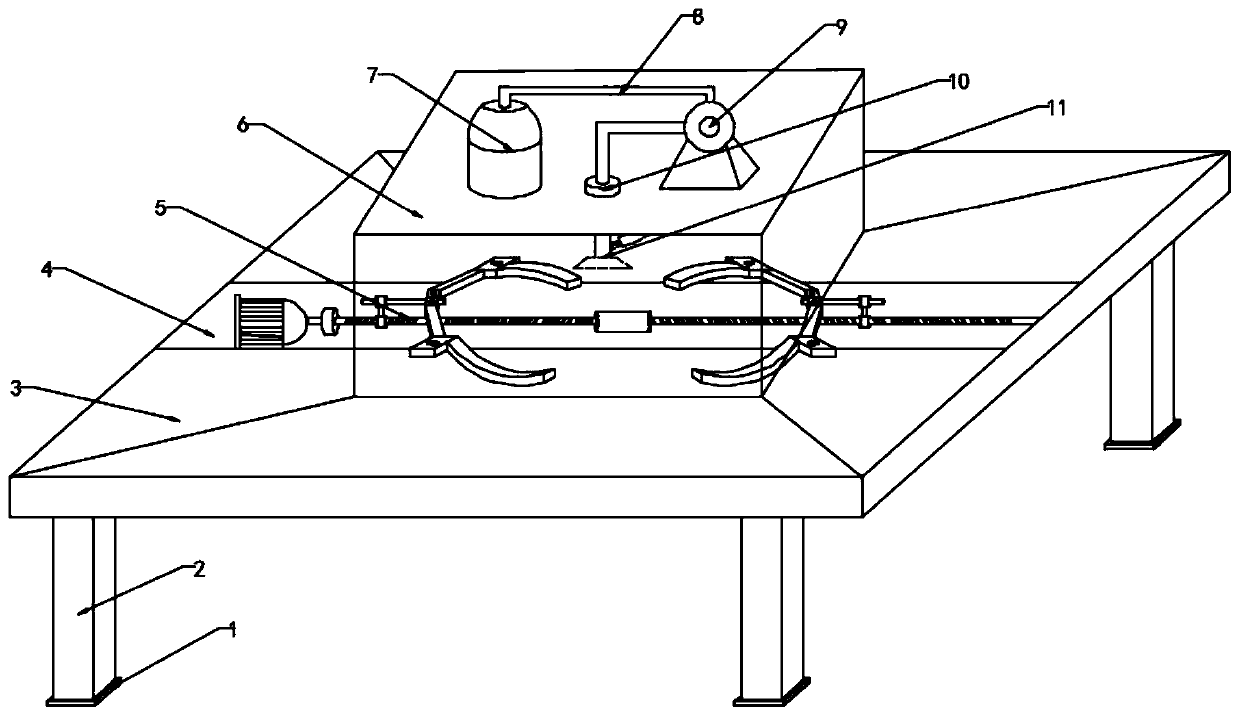

[0024] see figure 1 , in the embodiment 1 of the present invention, a kind of coloring device for production of anesthesia breathing mask, it comprises: workbench 3, is provided with slot 4 in the middle of described workbench 3, and glass shield 6 is installed on the slot 4, glass The front end of the shield 6 is provided with a closed door; the inside of the glass shield 6 is equipped with a clamping assembly 5 and a coloring assembly 11, and the upper end of the glass shield 6 is provided with a storage tank 7, a feeding pump 9 and a fixed terminal 10, The storage tank 7, the feed pump 9 and the fixed end 10 are connected through the feed pipe 8 in turn, and the lower end of the fixed end 10 is connected with the coloring assembly 11; the lower end of the workbench 3 is provided with a leg 2, A seat cushion 1 is installed at the lower end of the outrigger 2;

[0025] Open and close the door and place the anesthesia breathing mask inside the glass shield 6, clamp and fix th...

Embodiment 2

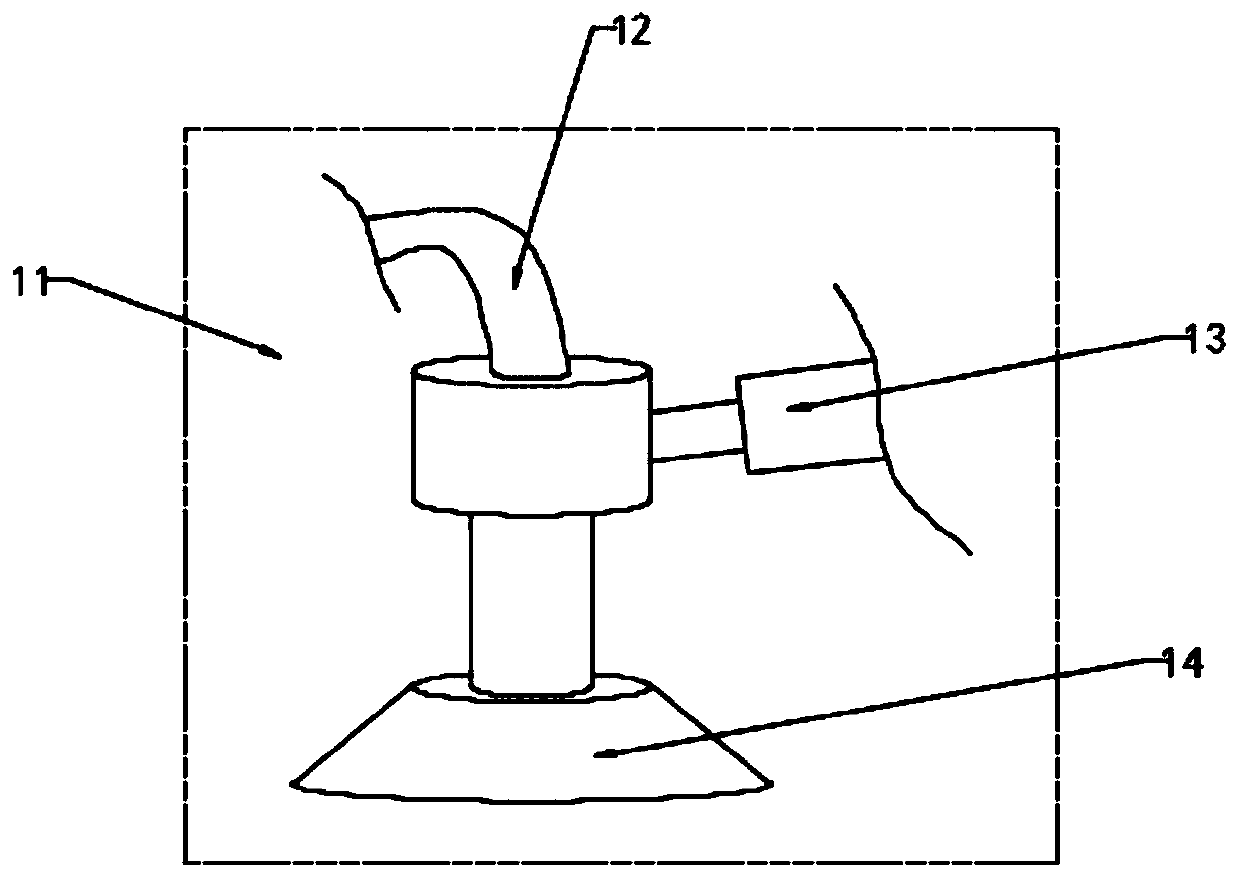

[0027] see figure 2 , further, the coloring assembly 11 includes a material guide tube 12, a temporary storage box, an electric telescopic rod 13 and a nozzle 14, the upper end of the material guide tube 12 is connected to the fixed end 10, and the lower end of the material guide tube 12 is connected to the temporary storage One end of the temporary storage box is connected to the electric telescopic rod 13, and the lower end of the temporary storage box is connected to the nozzle 14;

[0028] The feeding pump 9 draws the coloring paint inside the material storage tank 7 and delivers it to the nozzle 14 through the feed pipe 12 to spray it out to color the anesthesia breathing mask; during the coloring process, adjust the position of the nozzle 14 through the electric telescopic rod 13 Angle, so that the paint is evenly colored on the anesthesia breathing mask.

[0029] The remaining structural parts of embodiment 2 are the same as embodiment 1.

Embodiment 3

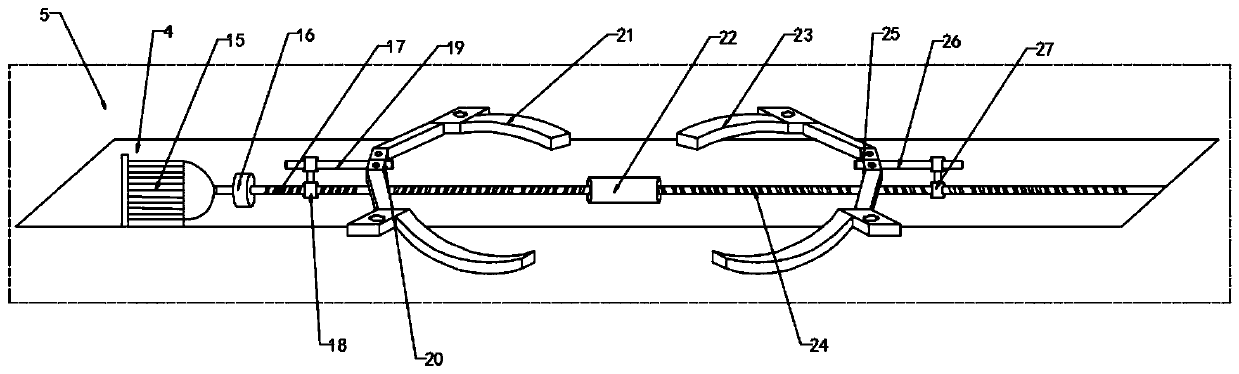

[0031] see image 3 Further, the clamping assembly 5 includes a motor 15, a reduction box 16, a first screw 17 and a second screw 24, the drive shaft of the motor 15 is connected to the reduction box 16, and one end of the reduction box 16 is connected to the first screw 17, the first screw mandrel 17 is connected with the second screw mandrel 24 through the connecting sleeve 22;

[0032] Further, the thread direction on the surface of the first screw rod 17 is opposite to the thread direction on the surface of the second screw rod 24;

[0033] Further, a first slider 18 is slidably installed on the first screw rod 17, and a first push rod 19 is arranged on the first slider 18, and one end of the first push rod 19 is connected to the first connecting terminal 20, and the first The first clamping block 21 is hinged and movable on both sides of the connection end 20;

[0034] Specifically, the number of the first clamping blocks 21 is two, and the middle of the two first clamp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap