Emergency escape equipment for rail transit vehicle

A technology for rail transit and traffic vehicles, which is applied in the field of emergency escape equipment for rail transit vehicles. It can solve problems such as rope wear, narrow application range, and decreased safety factor, and achieve the effects of convenient recycling, wide application range, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

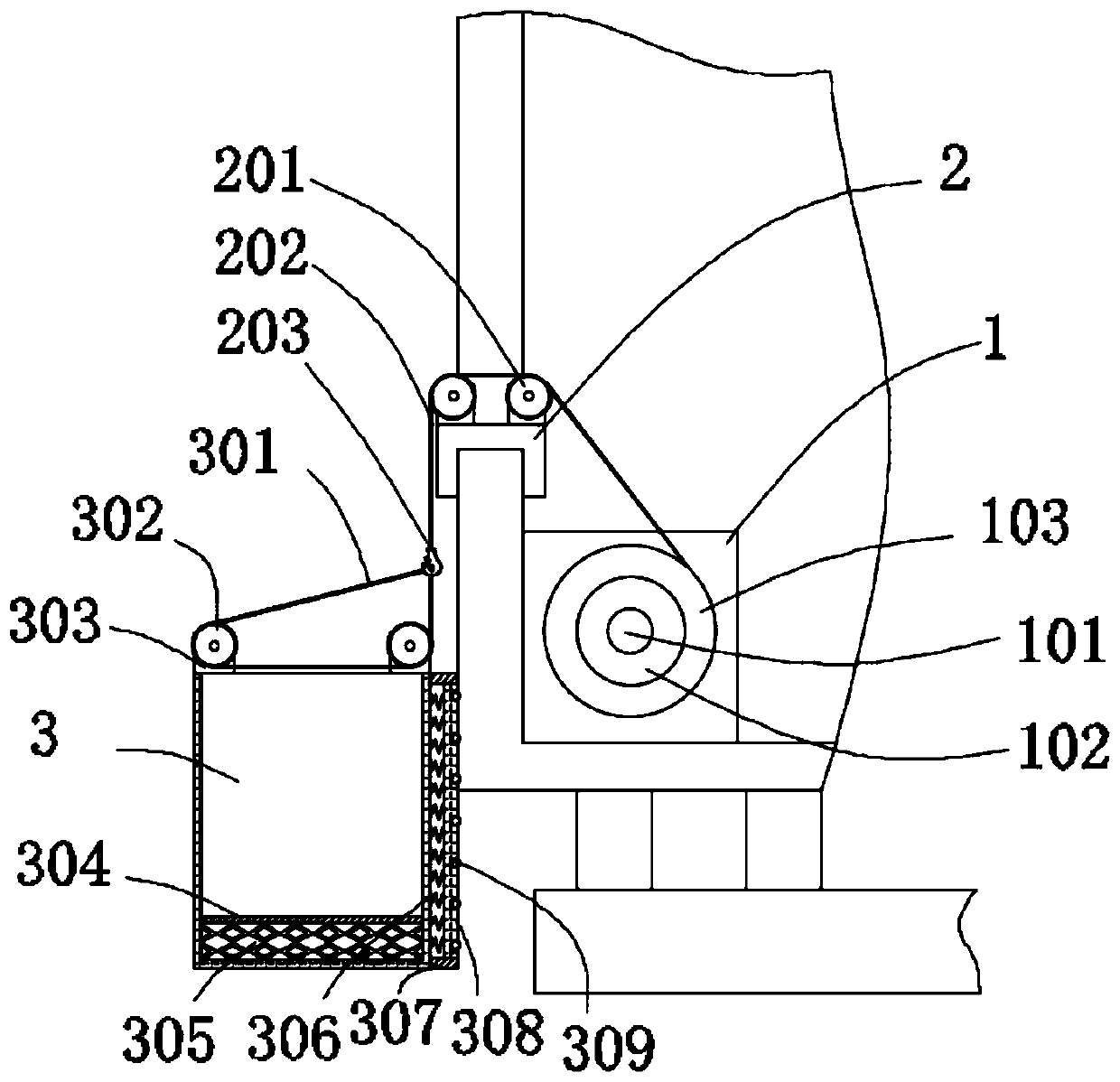

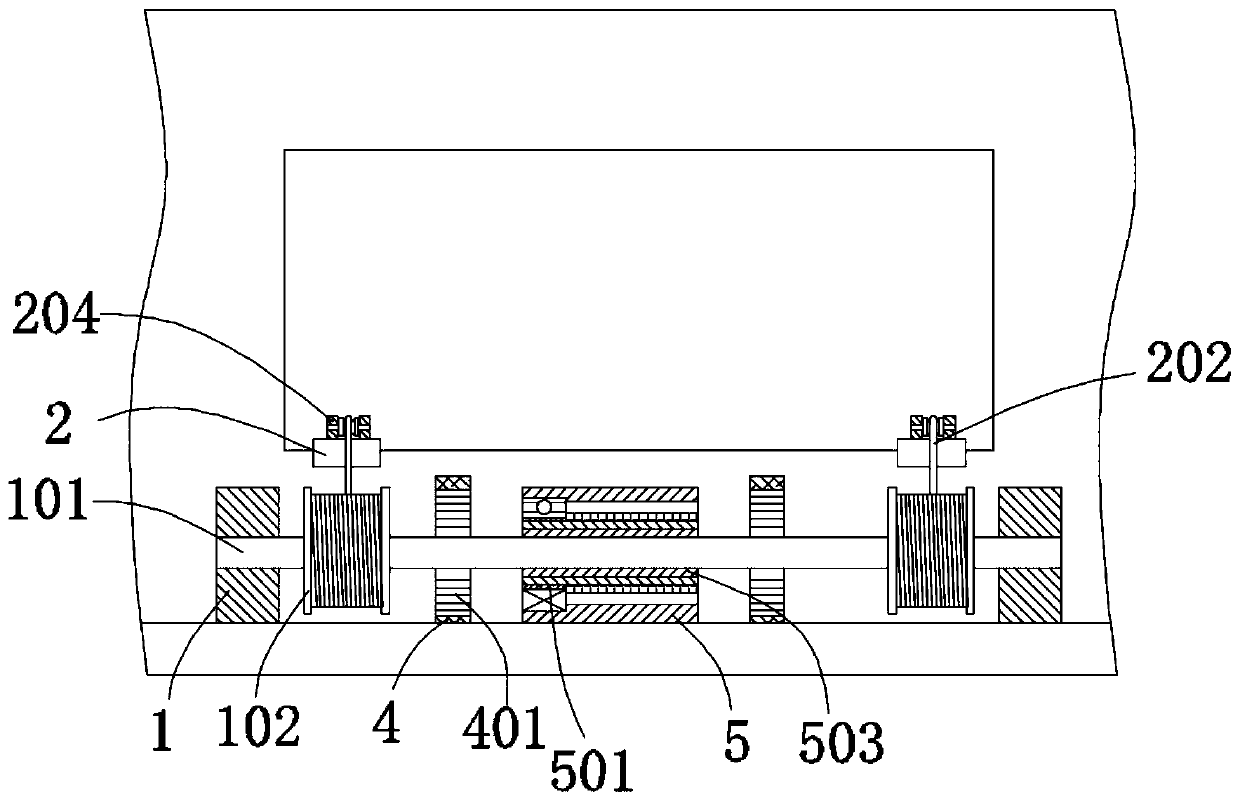

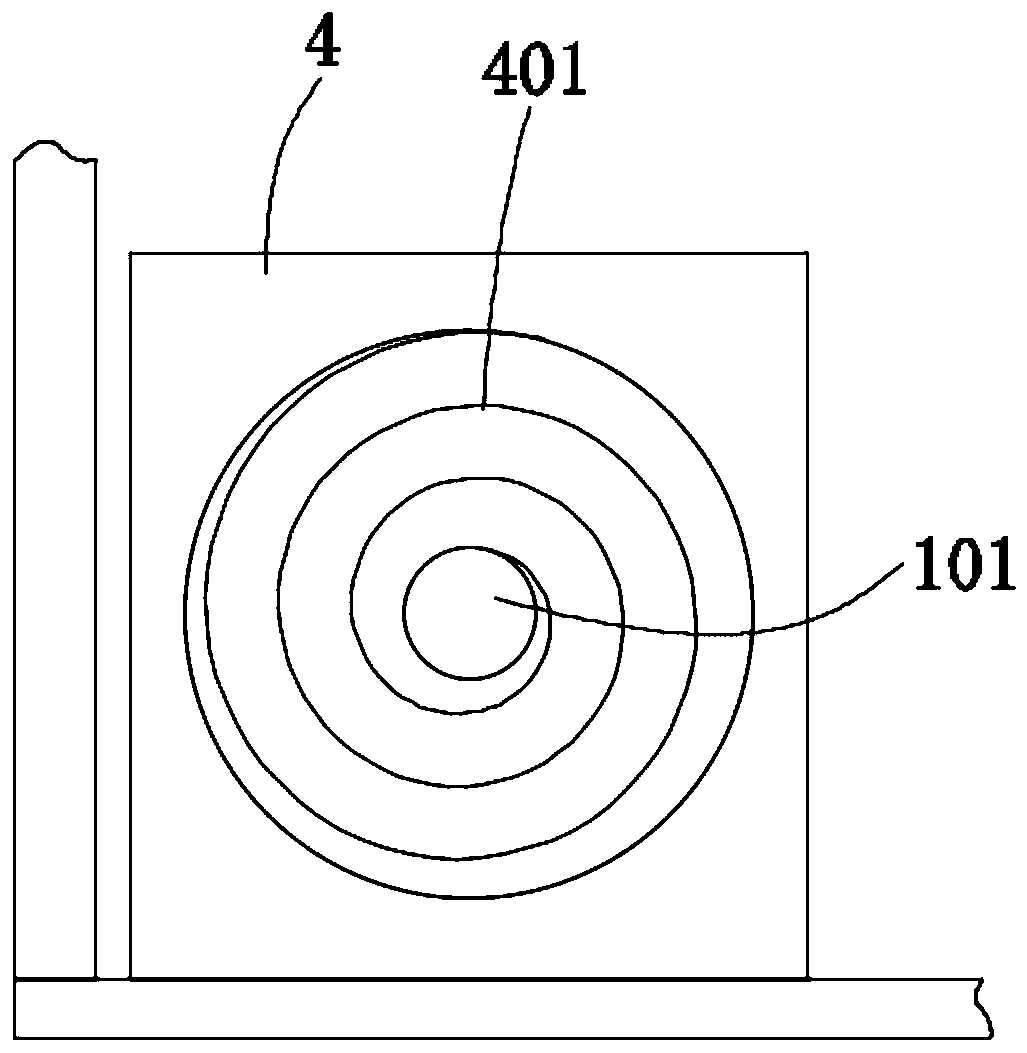

[0027] refer to Figure 1-7 , an emergency escape device for a rail transit vehicle, comprising a hanging basket 3, two clamping blocks 2 and two first support seats 1, the inner walls of the two first support seats 1 are connected with the same rotating shaft 101 through bearings, and the first The support base 1 is welded to the inner bottom of the rail transit car, and both sides of the outer wall of the rotating shaft 101 are sleeved with rope winding rollers 102, and the outer wall of the rope winding roller 102 is sleeved with a rope roll 103, and the rope output end of the rope roll 103 is pulled out There is a rope 202, the outer wall of the rotating shaft 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap