Efficient balanced rotary cutting machine for bidirectional rotary cutting

A rotary cutting machine and balanced technology, which is applied in the manufacture of thin wood chips, wood processing appliances, manufacturing tools, etc., can solve the problems of increasing the cost of rotary cutting equipment, and achieve the effect of improving the rotary cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

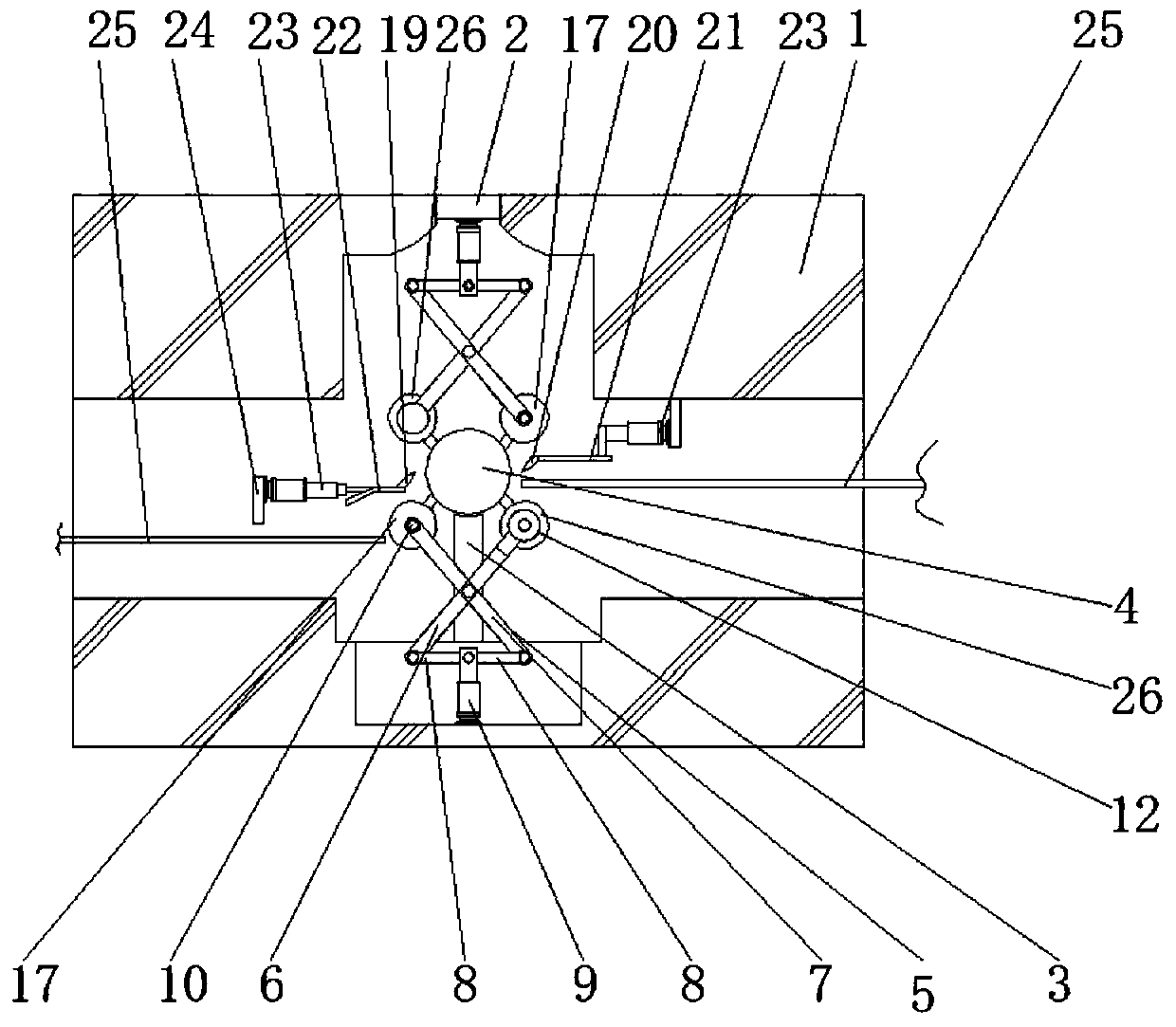

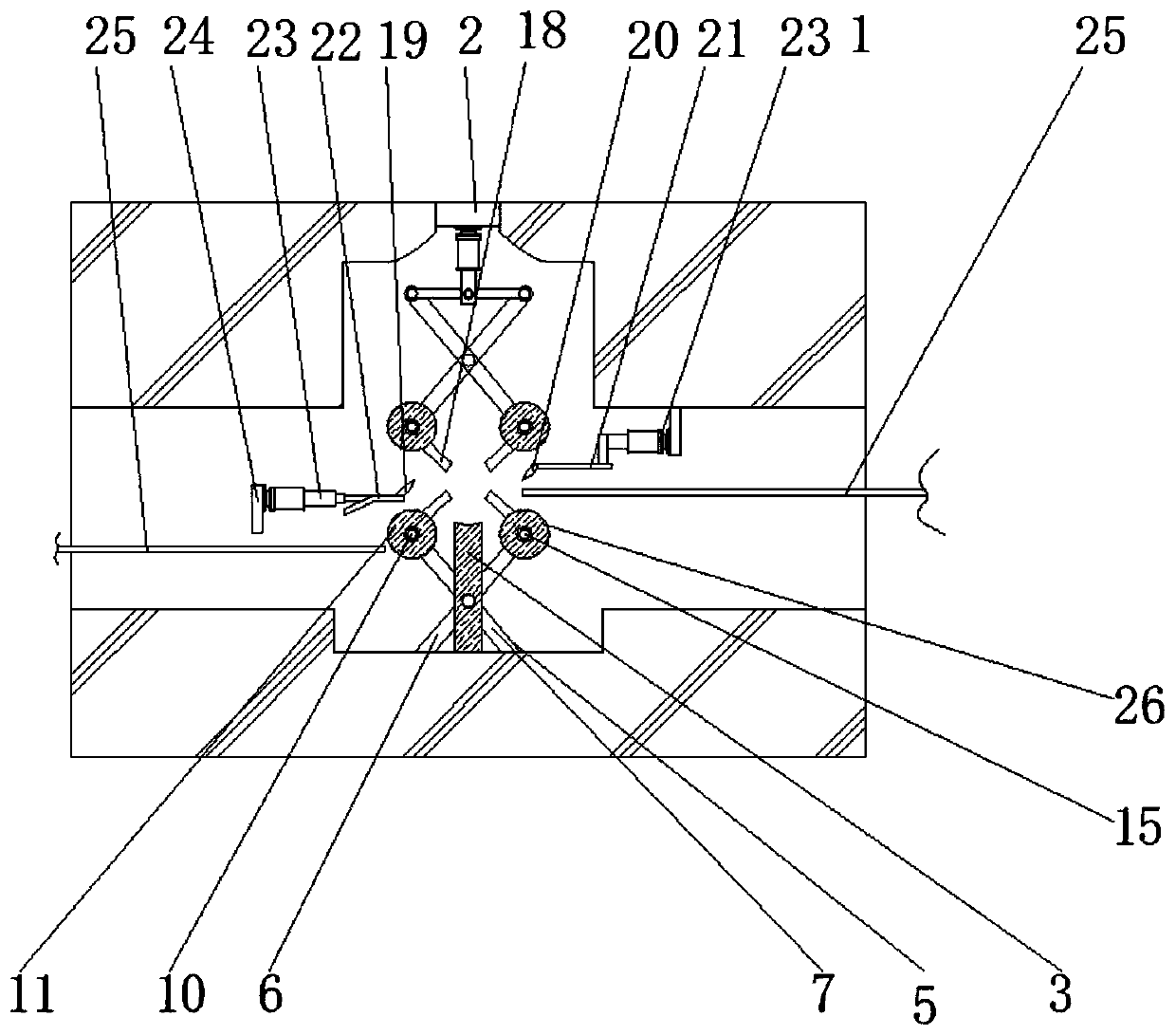

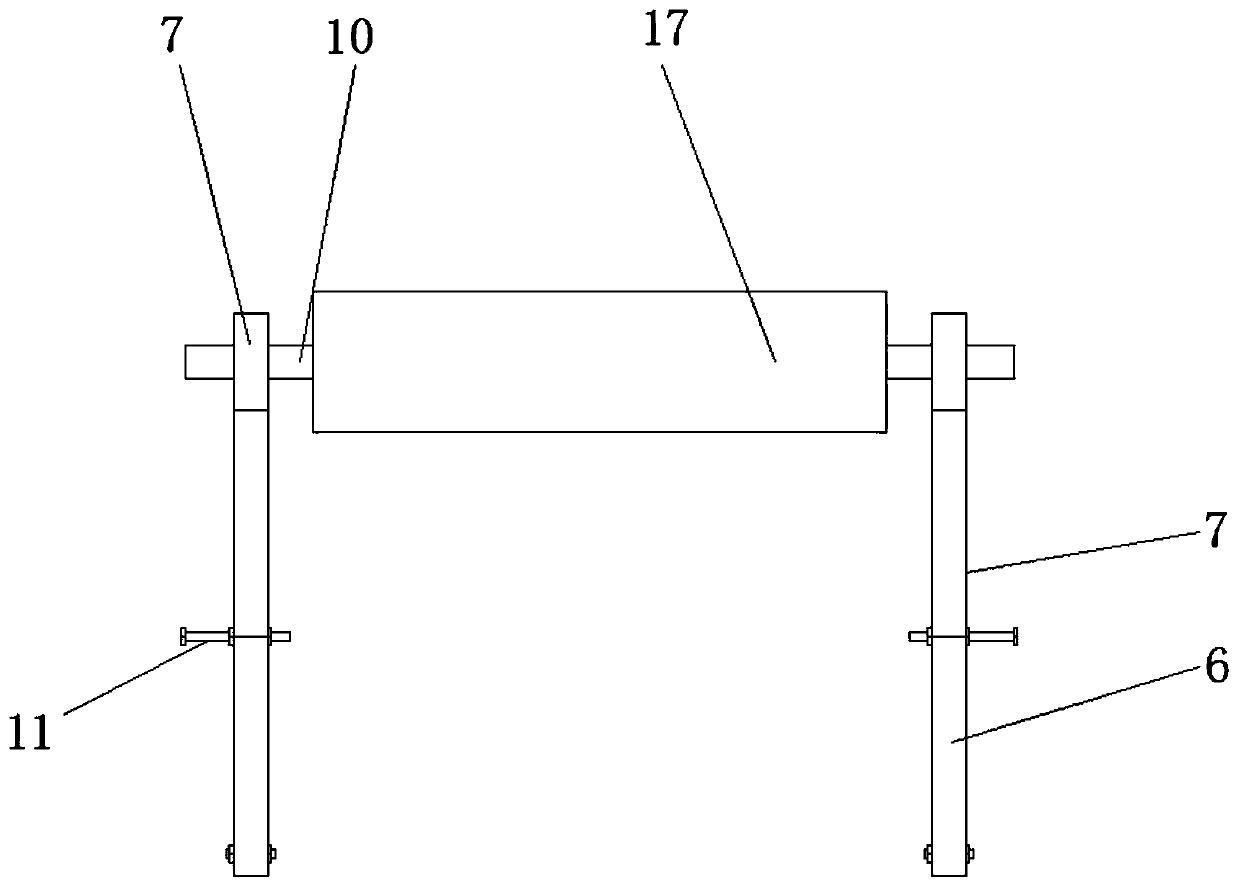

[0025] Such as Figure 1-4 A high-efficiency balanced rotary cutter with two-way rotary cutting shown includes a housing 1 and a feed port 2. The inside of the housing 1 is vertically provided with a support platform 3 along its width direction, and the top of the housing 1 is provided with a The feed port 2 located directly above the support platform 3 has an arc-shaped top end, and the arrangement of the arc-shaped structure on the top surface of the support platform 3 effectively improves the degree of fit between it and the outer wall of the wood 4. In this way, the two sides of the contacted wood 4 are limited, thereby providing convenience for the loading of the wood 4, and also providing conditions for the later rotary cutting of the wood 4. The top of the support table 3 is placed with a wood 4;

[0026] The upper and lower ends of the interior of the housing 1 are provided with two sets of support structures facing each other, and each set of support mechanisms inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com