A kind of preparation device and preparation method of chalcogenide glass fiber Bragg grating

A fiber Bragg, chalcogenide glass technology, applied in cladding fibers, optical waveguides, light guides, etc., can solve the problems of limited length of fiber Bragg grating center wavelength grating, highly dependent on phase mask, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

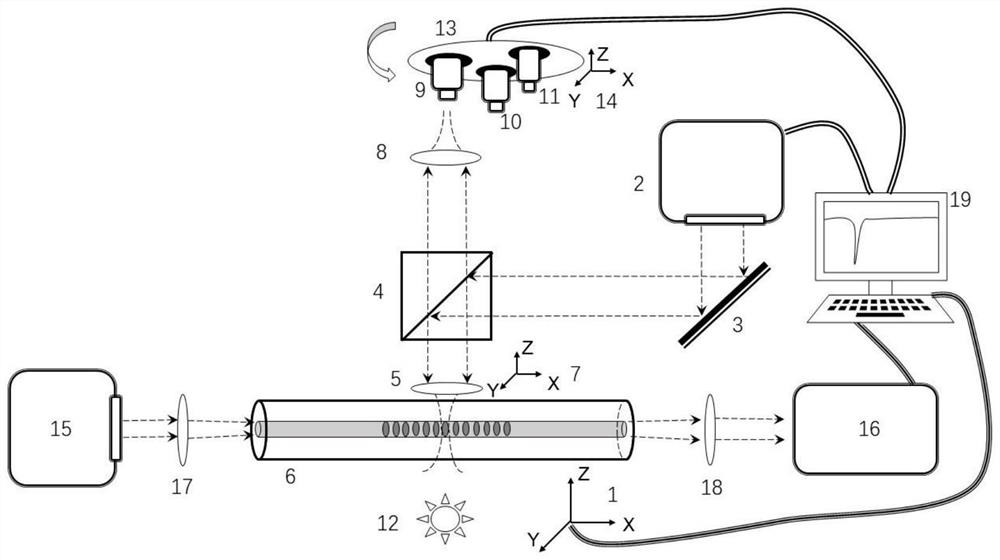

[0038] The present invention also provides a method for preparing a chalcogenide glass fiber Bragg grating based on the above device, comprising the following steps:

[0039] S1. According to the bandgap wavelength band of the host material of the chalcogenide glass optical fiber 6 used, select the corresponding wavelength tunable femtosecond laser light source 2 grating writing wavelength, with the help of reflective gold mirror 3, dichroic mirror 4, calcium fluoride Lens one 5, the first three-dimensional adjustment frame 7 make the femtosecond laser focus in the core of the chalcogenide glass optical fiber 6;

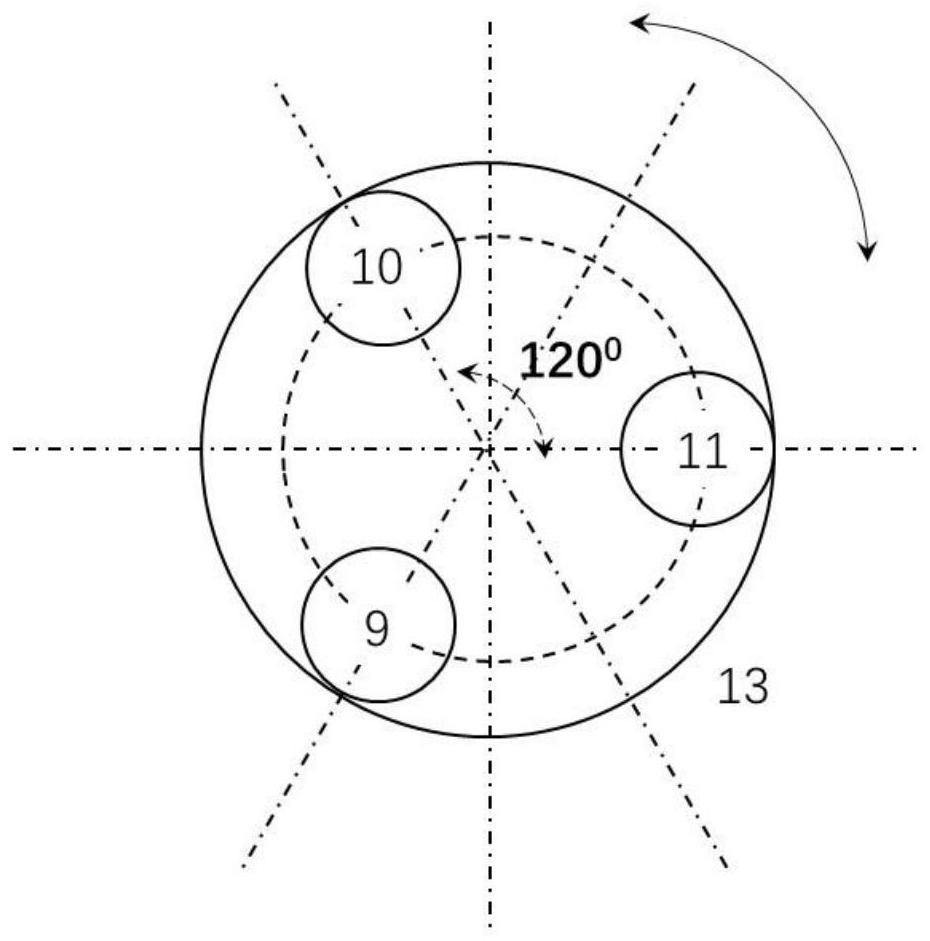

[0040] S2. According to the grating writing wavelength, switch to the visible light-near-infrared silicon-based camera 9 with a working band of 0.4-1 μm or the near-infrared-mid-infrared extended InGaAs camera 10 with a working band of 1-2.4 μm or a working band of 2.5 through the mechanical turntable 13 The mid-infrared mercury cadmium telluride camera 11 of -10 μm ...

Embodiment 1

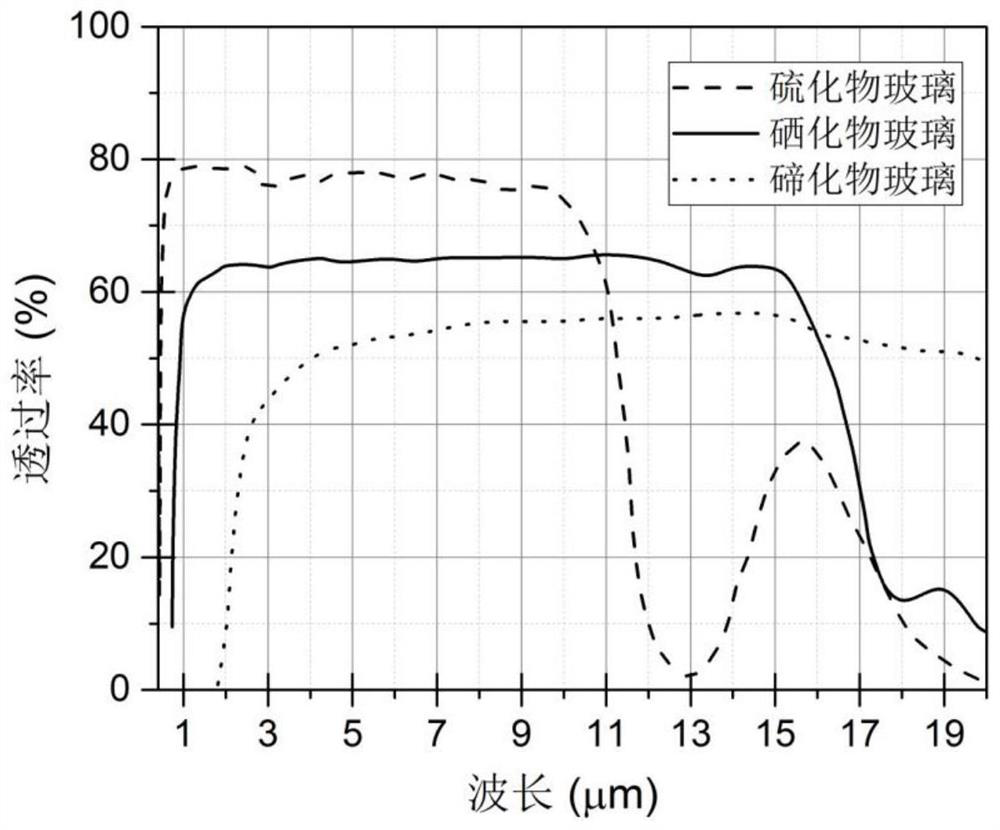

[0043] Embodiment 1: Chalcogenide glass fiber 6 uses sulfide glass single-mode fiber (core: As 0.40 S 0.60 , cladding: As 0.39 S 0.61 ), the fiber diameter is 160 μm, and the core diameter is 4 μm; its bandgap wavelength is located at ~0.52 μm (such as image 3 shown). Firstly, the optical fiber is fixed on the nano-precision three-dimensional mechanical mobile platform 1, the femtosecond laser wavelength is selected as 0.8 μm, the pulse repetition frequency is 1 kHz, the pulse width is 120 femtoseconds, and the single pulse energy is 5 nanojoules. Switch to the visible light-near-infrared silicon-based camera 9 with a working wavelength of 0.4-1.1 μm through the mechanical turntable 13, and use the auxiliary imaging system on the side of the fiber to realize the accuracy of the focus position (including the centrality and the upper and lower positions) of the femtosecond laser spot in the fiber core Position and make the X-moving direction of the nanometer-precision three...

Embodiment 2

[0044] Embodiment 2: Chalcogenide glass fiber 6 uses selenide glass single-mode fiber (core: Ge 0.1 As 0.3 Se 0.6 , cladding: Ge 0.13 As 0.2 S 0.67 ), the fiber diameter is 240 μm, and the core diameter is 6.5 μm. Its bandgap wavelength is located at 0.8μm (such as image 3 shown). Firstly, the optical fiber is fixed on the nano-precision three-dimensional mechanical mobile platform 1, the femtosecond laser wavelength is selected as 1.5 μm, the pulse repetition frequency is 100 kHz, the pulse width is 100 femtosecond, and the single pulse energy is 0.1 nanojoule. Switch to the near-infrared-mid-infrared extended InGaAs camera 10 with a working band of 1-2.4 μm through the mechanical turntable 13, and realize the focus position (including centrality and up-down position) of the femtosecond laser spot in the fiber core by means of the fiber side auxiliary imaging system ), and make the X-moving direction of the nanometer-precision three-dimensional mechanical mobile platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com