Azobenzene polymer surface undulation grating photoetching machine based on guided mode interference

A technology of azobenzene and polymers, applied in the field of lithography machines, can solve the problems of long exposure time, high cost, complicated process, etc., and achieve the effects of reduced exposure time, short exposure time and simple optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

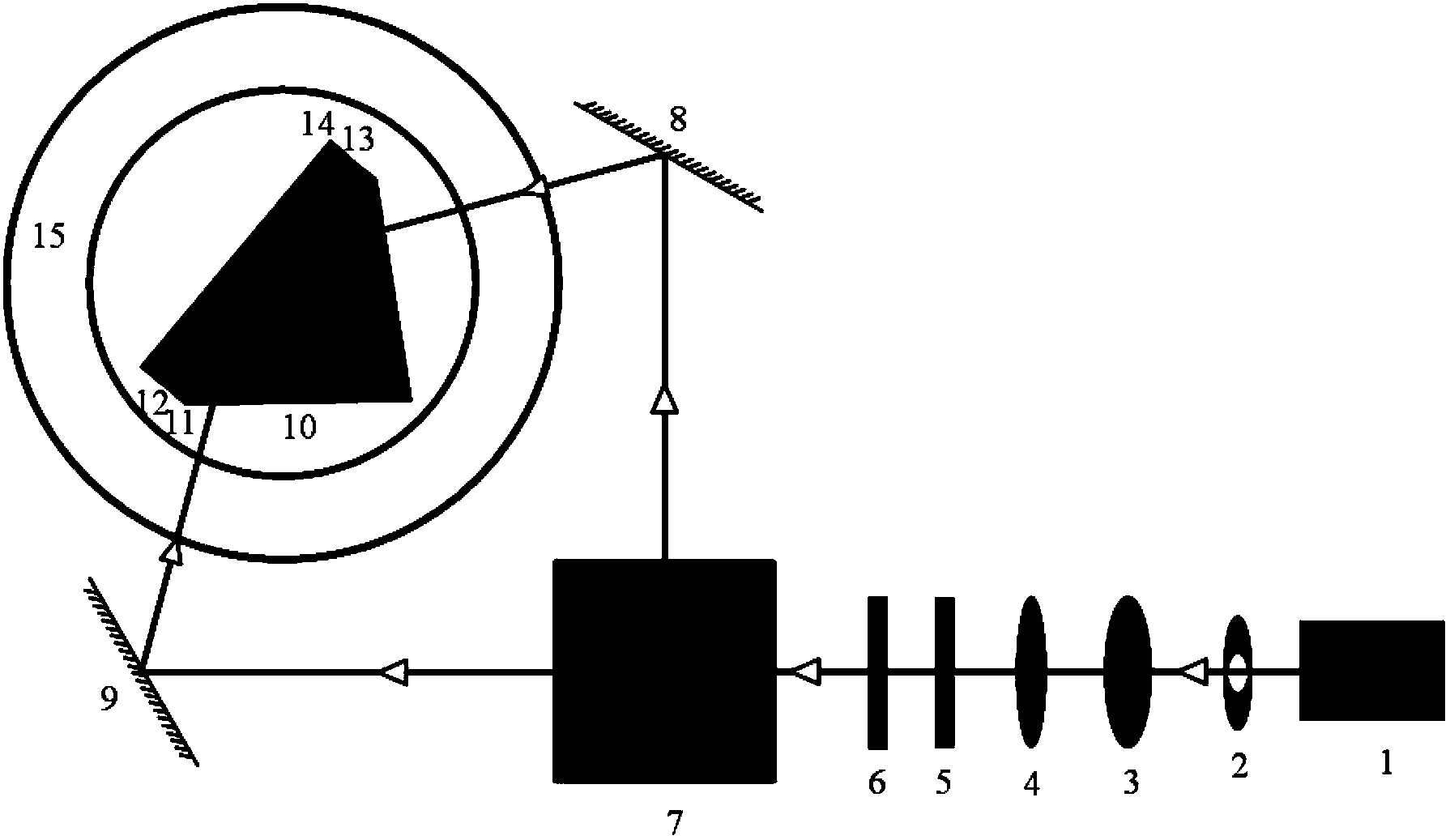

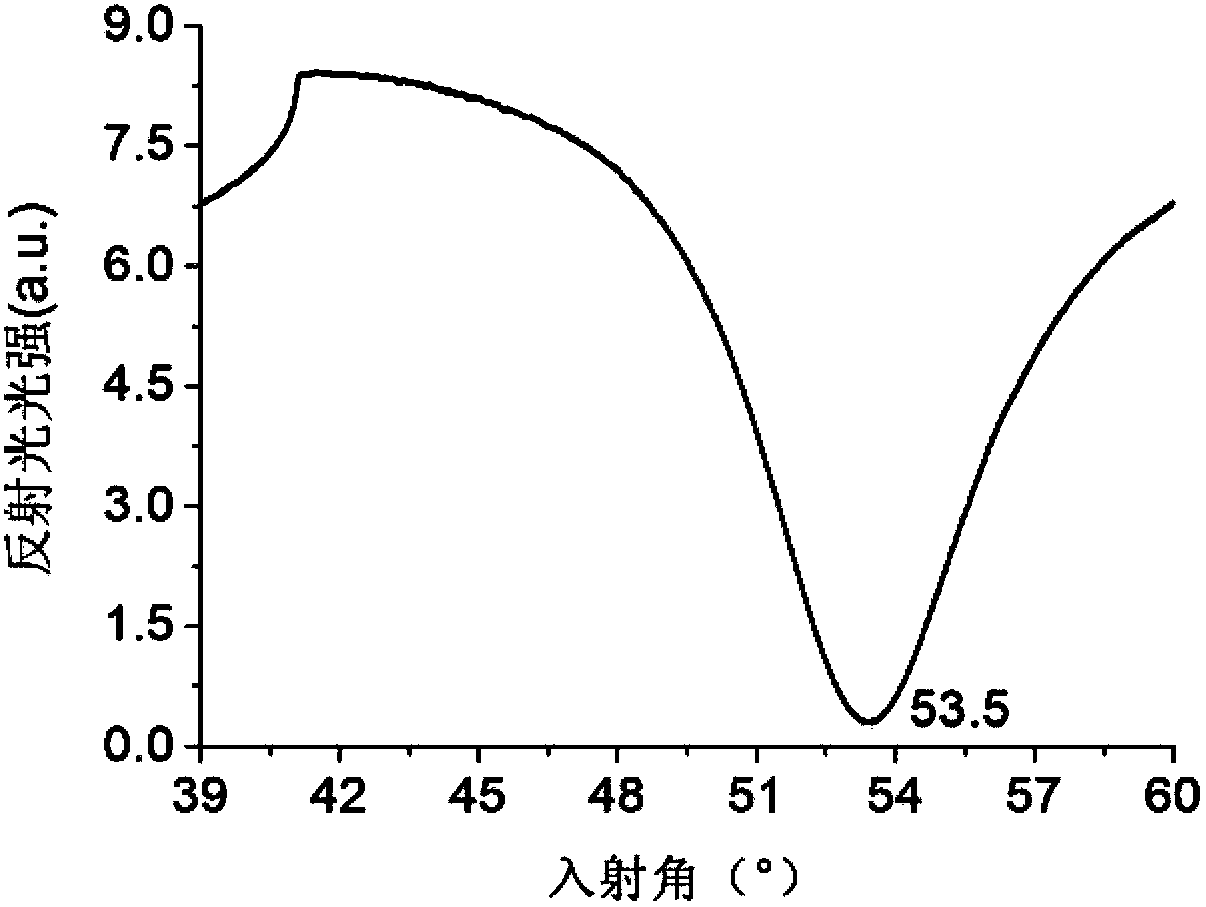

[0039] refer to figure 1 An azobenzene polymer surface relief grating lithography machine based on guided mode interference is shown, including: a laser light source 1, a photoelectric shutter 2, a short focal length lens 3, a long focal length lens 4, a half-wave plate 5, and a polarizer 6. Beam splitter 7, plane mirror A8, plane mirror B9, prism 10, matching oil 11, glass substrate 12, metal film 13, azobenzene polymer film 14, optical waveguide parameter measuring instrument 15; wherein, in A metal thin film 13 (25nm silver film) is vapor-deposited on the glass substrate 12, and then spin-coated with an azobenzene polymer cyclopentanone solution to obtain a 208nm thick azobenzene polymer film 14, and the glass substrate is coated with matching oil 11 12 is bonded with the prism 10, and placed in the center of the optical waveguide parameter measuring instrument 15. The polarizing direction of the polarizer 6 is adjusted to the horizontal direction to generate TM polarized ...

Embodiment 2

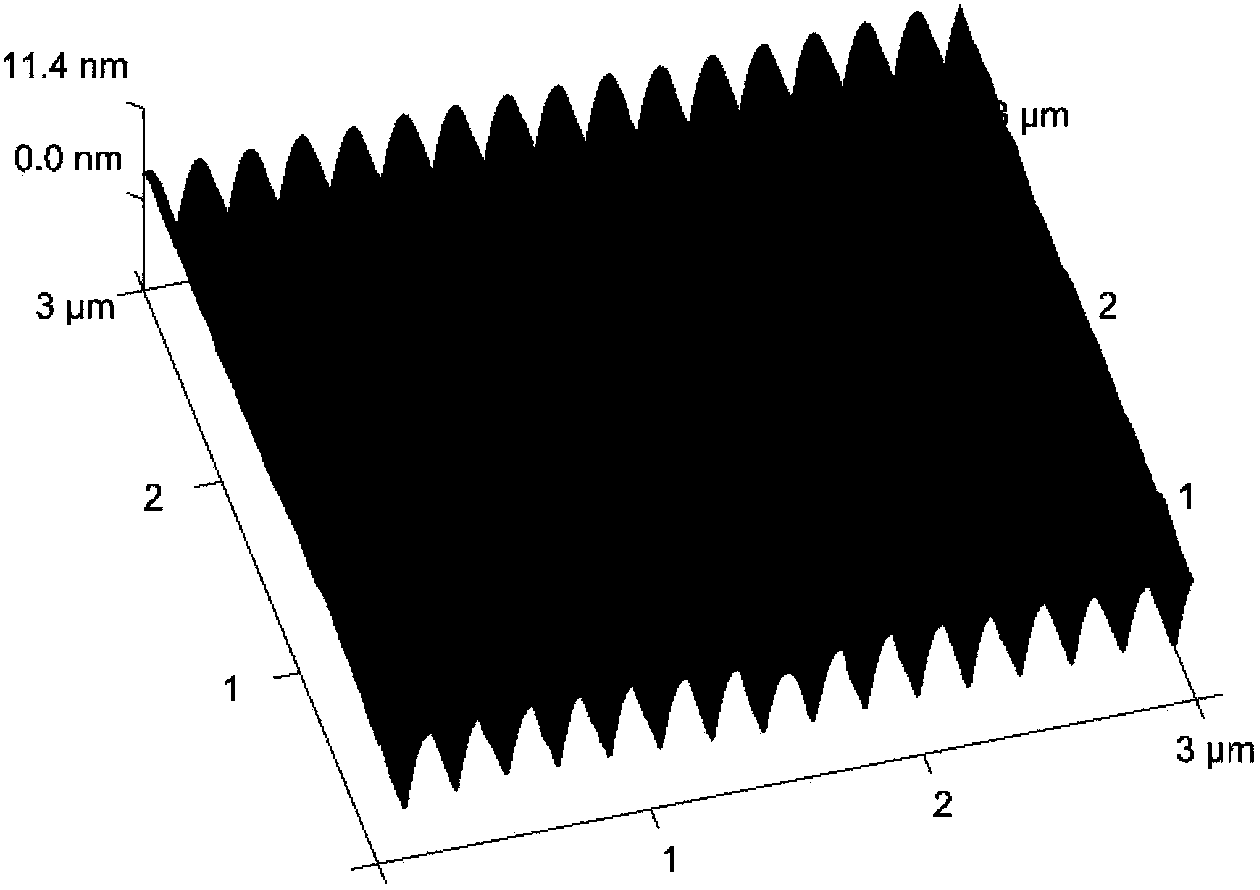

[0041] By changing the thickness of the azobenzene polymer film and the excited guided wave mode, the writing of subwavelength gratings with different periods can be realized. When the thickness of the azobenzene polymer film is 100nm, the polarization direction of the polarizer 6 is in the vertical direction, and the excitation angle of the excited TE1 mode is measured to be 52.8° under low-intensity laser conditions. The grating period of the subwavelength azobenzene polymer surface relief grating written under the conditions is 189nm, and its atomic force microscope photo is shown in Figure 4 .

[0042] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com