A pipe joint pressure fatigue test device and test method

A fatigue test and pipe joint technology, applied in the field of performance testing experimental devices, can solve the problems of high price of hydraulic reversing valves, sensitive drive of oil pollution, complicated test devices, etc., and achieve fast switching speed, low price and long service life of components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

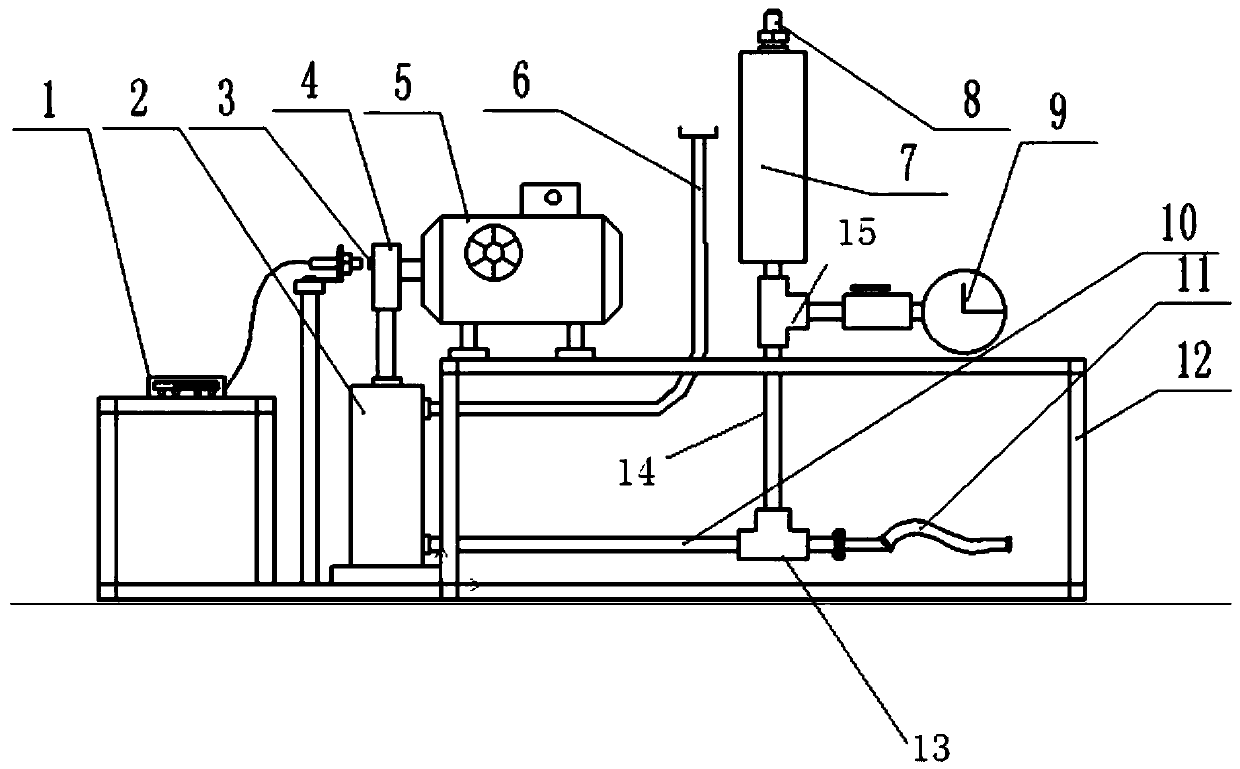

[0049] The invention provides a pipe joint pressure fatigue test device, which includes a support frame 12, a pressure generating device, a pressure transmission device, a pressure conversion device and a counting detection device, and the pressure generating device, the pressure transmission device, the pressure conversion device and the counting detection device are respectively Set on the support frame 12.

[0050] figure 1 In the schematic diagram of the pipe joint pressure fatigue test device shown, the support frame 12 is an experimental operation platform designed by 4040 thickened aluminum profiles according to the installation positions of each device, and can be designed according to needs.

[0051] The pressure generating device includes a set of 0.37KW stepless speed-adjusting deceleration motor 5, an eccentric cam 4 and a rear flange single-rod piston hydraulic cylinder 2 with an inner diameter of 32mm. The area of the high-pressure chamber of the cylinder mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com