A structural color film capable of visual measurement and its preparation method and application

A structural color and color technology, which is applied in the field of preparation of structural color films on polydimethylsiloxane substrates, can solve problems such as complex processes, and achieve the effects of simple process, reduced measurement difficulty, and easy control of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a structural color film of focused laser interference lithography in this example comprises the following specific steps:

[0052] Step 1, according to the mass ratio of 10:1, weigh the liquid PDMS and PDMS curing agent with an electronic scale, mix the weighed liquid PDMS and PDMS curing agent in the same beaker, stir in the same direction with a glass rod for 10 minutes, and stir After uniformity, use a disposable plastic straw to absorb the evenly stirred PDMS from the beaker, drop it on a clean glass slide placed horizontally, and let it stand at room temperature 20°C for 5 minutes. PDMS will spread on the glass slide and form when stirring. The bubbles will also be discharged when standing still. After standing still, place the slide with PDMS on the glue spreader, first keep it at 500r / min for 10 seconds, then keep it at 1500r / min for 60 seconds, spin coat Then put it on the heating plate to heat and cure. The heating temperature is 80°C-100...

Embodiment 2

[0061] A method for preparing a structural color film of focused laser interference lithography in this example comprises the following specific steps:

[0062] Step 1, according to the mass ratio of 10:1, weigh the liquid PDMS and PDMS curing agent with an electronic scale, mix the weighed liquid PDMS and PDMS curing agent in the same beaker, stir in the same direction with a glass rod for 10 minutes, and stir After uniformity, use a disposable plastic straw to absorb the evenly stirred PDMS from the beaker, drop it on a clean glass slide placed horizontally, and let it stand at room temperature for 5 minutes at 20°C. PDMS will naturally spread out on the surface of the glass slide. At the same time, the air bubbles formed during stirring will also be discharged when standing still. Put the slides with PDMS on the homogenizer after standing still, first keep it at a speed of 500r / min for 10 seconds, and then keep it at a speed of 1500r / min for 60 seconds. Seconds, after spin ...

Embodiment 3

[0070] In this example, a method for preparing a structural color film of focused laser interference lithography is combined with a flexible actuator to realize non-contact visual measurement of the curvature of the flexible actuator, including the following specific steps:

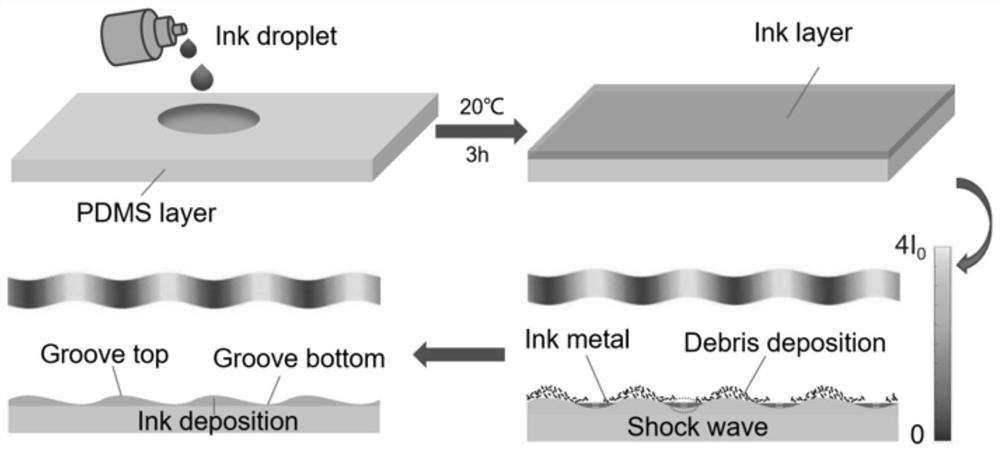

[0071] Step 1: Apply a layer of black ink on the position where the surface of the PDMS layer of the flexible actuator needs to be processed, using black water-based pen ink, and place the ink-coated flexible actuator sample at room temperature to dry the ink on the surface , to obtain a flexible actuator sample with a layer of ink layer on the surface;

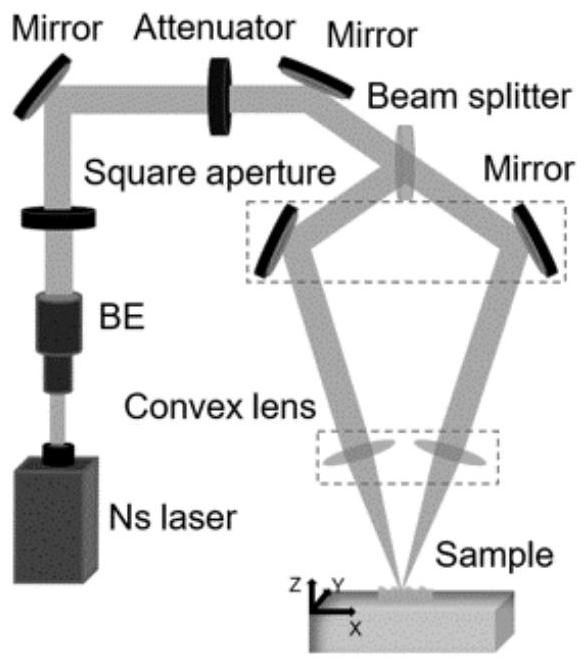

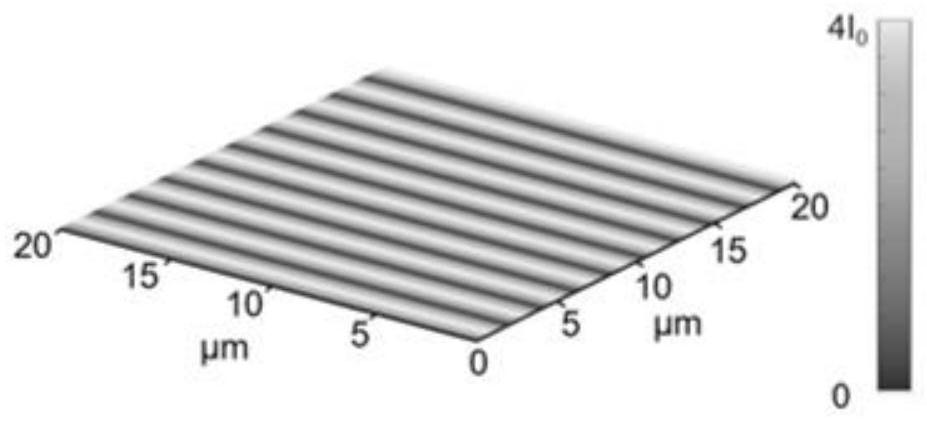

[0072] Step 2: Use a nanosecond laser with a center wavelength of 355nm, a pulse width of 10ns, and a repetition rate of 10Hz to perform focused laser interference lithography scanning on the part of the flexible actuator described in step 1 that needs to be processed. The laser interference lithography scanning processing system, as shown in Fig. 2 A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com